Method for preparing oxamide from dimethyl oxalate

A technology of dimethyl oxalate and oxamide, applied in the field of preparing oxamide, can solve problems such as unfavorable industrialization, high reaction temperature, high cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

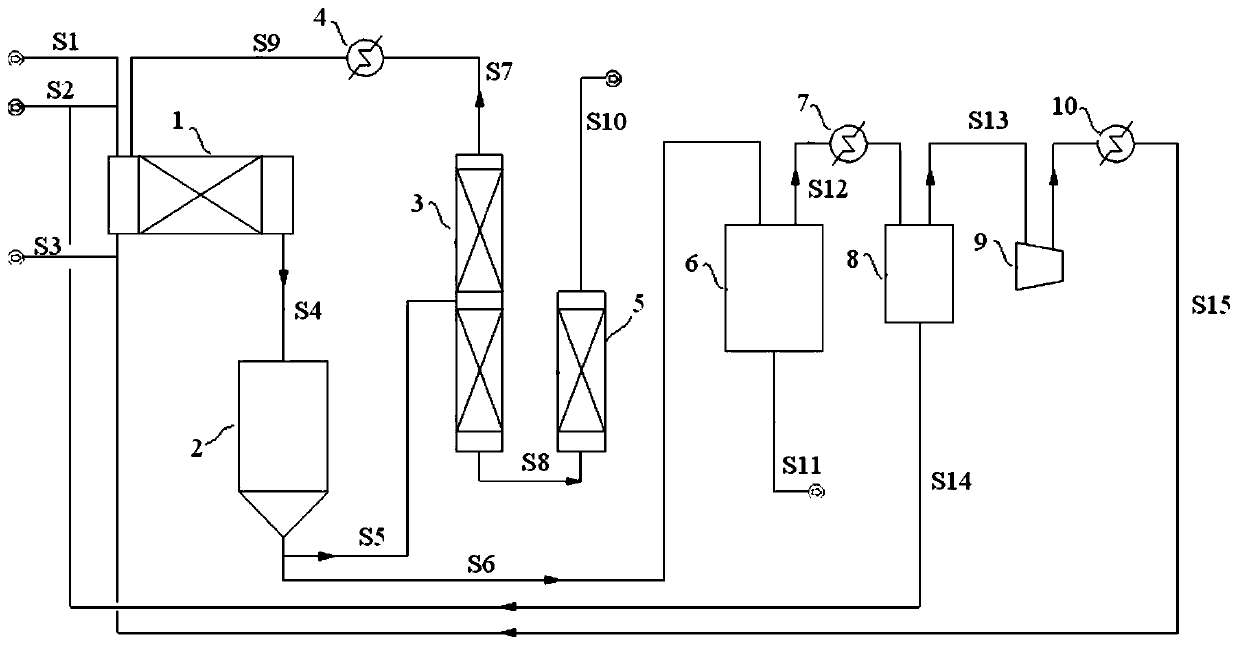

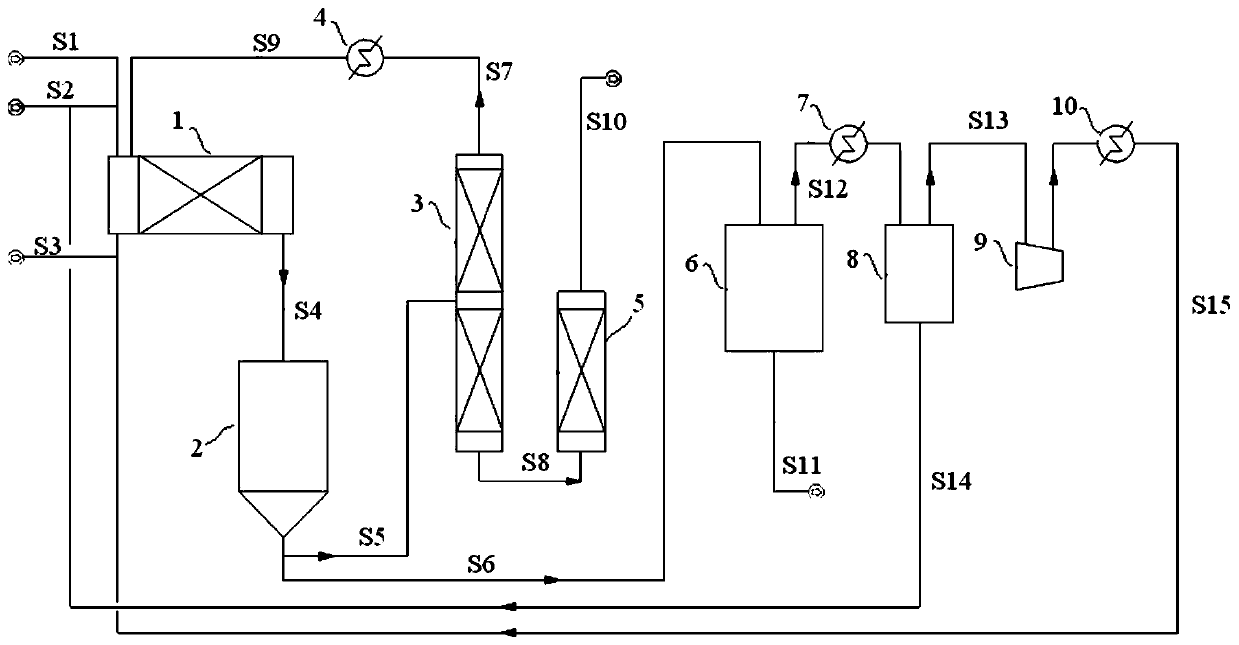

[0055] The mixed solution of dimethyl oxalate and methanol, fresh liquid ammonia and recovered liquid ammonia enter the ammonolysis reactor 1, and the molar ratio of dimethyl oxalate, methanol and ammonia is 1:4:4. At a temperature of 60° C., an ammonolysis reaction occurs under a pressure of 0.6 MPa for a reaction time of 1 h, and an ammonolysis product stream S4 is generated. The reacted ammonolysis product stream S4 enters the solid-liquid separator 2, and the separated first solid phase stream S6 enters the drier 6. The temperature of the drier 6 is 80° C., and is dried for 6 hours to obtain the oxamide product S11. The first liquid stream S5 enters the rectifying column 3 of methanol through a pump, and the rectifying conditions are as follows: feed pressure is 0.7Mpa (G), temperature is 60°C, tower bottom pressure is 0.71Mpa (G), and temperature is 120°C ℃, the pressure at the top of the tower is 0.69Mpa (G), the temperature is 14°C, 15 trays, the reflux ratio is 0.6, th...

Embodiment 2

[0057] The mixed solution of dimethyl oxalate and methanol, fresh liquid ammonia and recovered liquid ammonia enter the ammonolysis reactor 1, and the molar ratio of dimethyl oxalate, methanol and ammonia is 1:2:4. At a temperature of 80° C., an ammonolysis reaction occurs under a pressure of 1.2 MPa for a reaction time of 0.5 h, and an ammonolysis product stream S4 is generated. The reacted ammonolysis product stream S4 enters the solid-liquid separator 2, and the separated first solid phase stream S6 is oxamide and enters the drier 6. The temperature of the drier 6 is 80° C. and dried for 6 hours. The first liquid phase stream S5 enters the rectification column 3 of methanol through a pump, and the conditions of rectification: feed pressure is 1.3Mpa (G), temperature is 100°C, tower bottom pressure is 1.31Mpa (G), temperature is 148°C , the top pressure is 1.29Mpa (G), the temperature is 34°C, 15 trays, and the reflux ratio is 0.6. The gaseous phase at the top of methanol r...

Embodiment 3

[0059]The mixed solution of dimethyl oxalate and methanol, fresh liquid ammonia and recovered liquid ammonia enter the ammonolysis reactor 1, and the molar ratio of dimethyl oxalate, methanol and ammonia is 1:4:6. At a temperature of 100° C. and a pressure of 1.0 MPa, an ammonolysis reaction occurs for a reaction time of 0.5 h, and an ammonolysis product stream S4 is generated. The reacted ammonolysis product stream S4 enters the solid-liquid separator 2, and the separated first solid phase stream S6 is oxamide and enters the drier 6. The temperature of the drier 6 is 80° C., and is dried for 6 hours to obtain the oxamide product S11. The first liquid stream S5 enters the rectification tower 3 of methanol through a pump, and the conditions of rectification: feed pressure is 1.1Mpa(G), temperature is 80°C, tower bottom pressure is 1.11Mpa(G), temperature is 140°C , the top pressure is 1.09Mpa (G), the temperature is 28°C, 15 trays, and the reflux ratio is 0.6. The gas phase at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com