Heating material for carbon dioxide cracking device

A heating material, carbon dioxide technology, applied in the direction of compressed gas generation, offensive equipment, explosives, etc., can solve the problems that liquid carbon dioxide cannot expand rapidly, the blasting energy is not high, and affects the blasting process, etc., achieving high flatness and high calorific value , to ensure the effect of safety and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

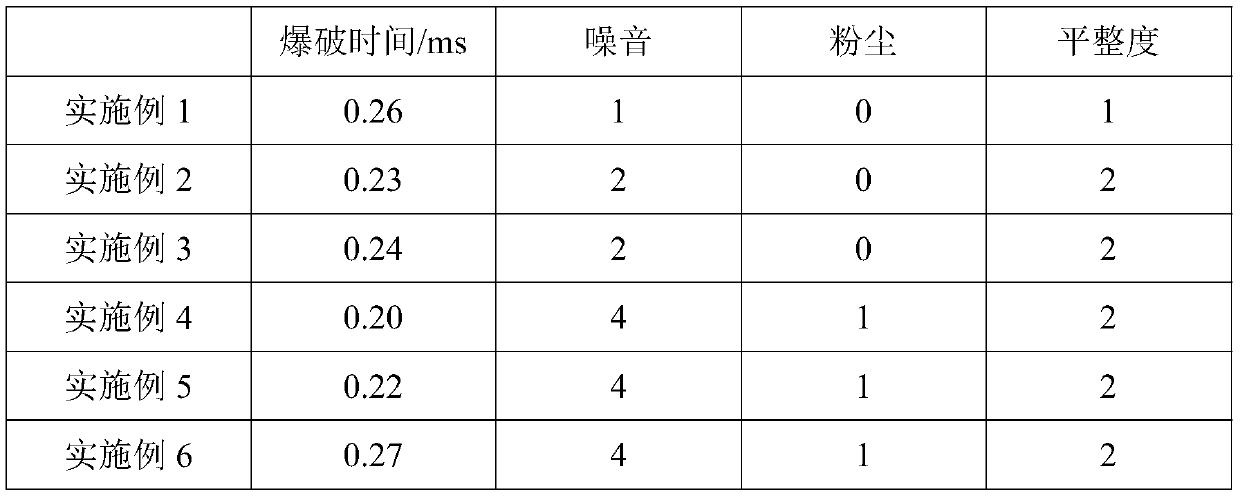

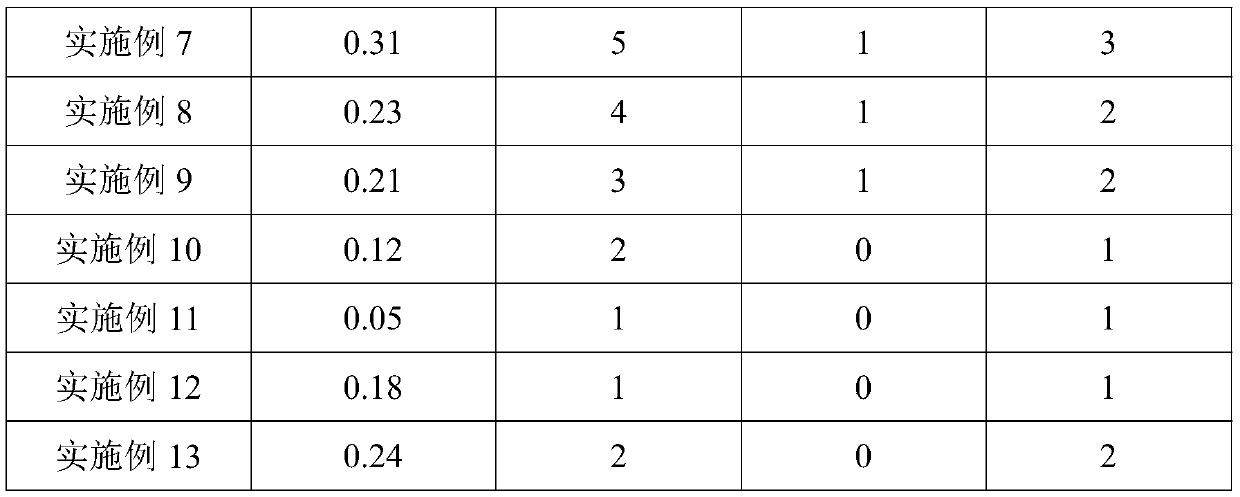

Embodiment 1

[0057] Embodiment 1: Provide a kind of exothermic material for carbon dioxide cracker, raw material comprises 0.4 weight part of cerium, 2 weight parts of metal powder, 18 weight parts of salicylic acid, 55 weight parts of potassium permanganate, 22 weight parts of ammonium compound and 8 parts by weight of ash powder. Wherein, ashes include plant ash, sulfur, hemp stalk ash, charcoal powder, and the weight ratio among plant ash, sulfur, hemp stalk ash, charcoal powder is 1:0.01:1:10; Described ammonium compound is ammonium nitrate and A mixture of ammonium molybdate, wherein the weight ratio of ammonium nitrate and ammonium molybdate is 4.5:1.2; the metal powder is a mixture of beryllium powder, magnesium powder and lithium powder, and its mass ratio is 1:2.5:0.8; the magnesium powder The average particle size is 65nm.

[0058] Blasting method: add the carbon dioxide blasting composition into the carbon dioxide blaster, and send the carbon dioxide blaster into the blast hole...

Embodiment 2

[0059] Embodiment 2: Provide a kind of exothermic material for carbon dioxide cracker, raw material comprises 0.4 weight part of cerium, 2 weight parts of metal powder, 18 weight parts of salicylic acid, 55 weight parts of potassium permanganate, 22 weight parts of ammonium compound and 8 parts by weight of ash powder. Wherein, the ash powder includes plant ash, sulfur, hemp stalk ash, and charcoal powder, and the weight ratio between plant ash, sulfur, hemp stalk ash, and charcoal powder is 1:0.01:1:10; the ammonium compound is ammonium nitrate; The metal powder is a mixture of beryllium powder, magnesium powder and lithium powder with a mass ratio of 1:2.5:0.8; the average particle size of the magnesium powder is 65nm.

[0060]Blasting method: add the carbon dioxide blasting composition into the carbon dioxide blaster, and send the carbon dioxide blaster into the blast hole, wherein the weight ratio of the heating material for the carbon dioxide cracker to the liquid carbon ...

Embodiment 3

[0061] Embodiment 3: Provide a kind of exothermic material for carbon dioxide cracker, raw material comprises 0.4 weight part of cerium, 2 weight parts of metal powder, 18 weight parts of salicylic acid, 55 weight parts of potassium permanganate, 22 weight parts of ammonium compound and 8 parts by weight of ash powder. Wherein, ashes include plant ash, sulfur, hemp ash, charcoal powder, and the weight ratio between plant ash, sulfur, hemp ash and charcoal powder is 1:0.01:1:10; the ammonium compound is ammonium molybdate ; The metal powder is a mixture of beryllium powder, magnesium powder and lithium powder, the mass ratio of which is 1:2.5:0.8; the average particle size of the magnesium powder is 65nm.

[0062] Blasting method: add the carbon dioxide blasting composition into the carbon dioxide blaster, and send the carbon dioxide blaster into the blast hole, wherein the weight ratio of the heating material for the carbon dioxide cracker to the liquid carbon dioxide is 0.08:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com