PAH-containing composite inhibitor as well as preparation method and application thereof

A technology of compound inhibitor and mixed solution, which is applied in chemical instruments and methods, preparation of alkali metal aluminate/alumina/aluminum hydroxide, aluminum compound, etc. Ideal and other issues, to achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

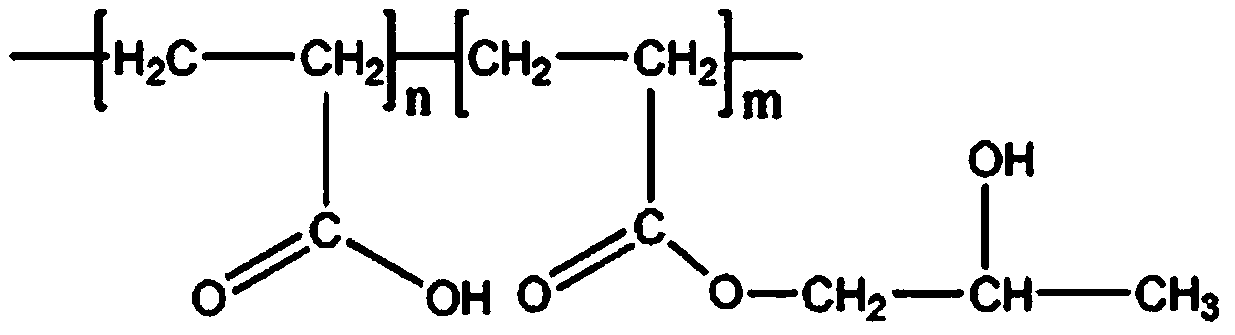

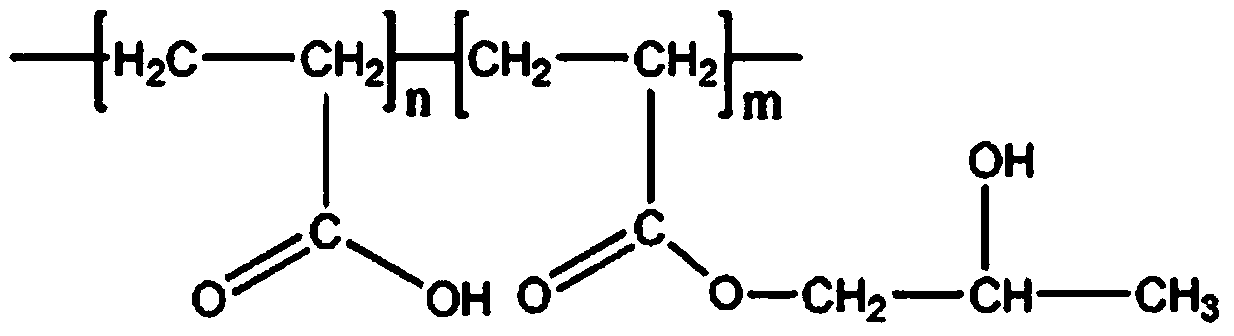

[0038] Embodiment 1 (preparation of acrylic acid-hydroxypropyl acrylate copolymer PAH):

[0039] Weigh 0.13g of ammonium persulfate and put it in a 100ml four-neck flask, add 17ml of distilled water, heat the water bath at 30°C, stir and dissolve, add 9.5g of acrylic acid, stir evenly to obtain mixed liquid A; In a beaker, add 17ml of distilled water to dissolve, after dissolving, add 8.6g of hydroxypropyl acrylate and 0.12g of mercaptopropionic acid to the beaker, stir and mix to obtain mixed solution B, add mixed solution B to the constant pressure funnel, slowly Add dropwise (1 drop / s) into a four-necked flask, and stir while adding dropwise. After the dropwise addition, the stirring was continued for 4h to obtain light yellow viscous liquid C. Pour the viscous liquid C into a large beaker containing 200ml of absolute ethanol, stir to dissolve the unreacted monomer, remove the supernatant after standing, and obtain a colorless transparent solid precipitate after centrifuga...

Embodiment 2

[0040] Embodiment 2 (preparation and application of composite inhibitor):

[0041] Weigh 0.021 g of the PAH polymer prepared in Example 1 and 0.014 g of commercially available sodium polyacrylate, and mix the two to obtain a composite inhibitor. The composite inhibitor of 0.035g (being 0.07% of clinker amount) is dissolved in the 200ml adjustment liquid A that leaching clinker is used to obtain adjustment liquid B, and adjustment liquid B is added in the there-necked flask, is placed in constant temperature water bath and is heated to 80 ℃ and keep warm. Weigh 50g of sintered alumina sintered clinker and add it to the adjustment liquid B, stir and mix evenly at a stirring speed of 300r / min, start the leaching timer, and the leaching time is 70min. After leaching, dry filter, accurately weigh the volume of the filtrate, analyze at constant volume, and calculate the leaching rate of alumina. Comparing the calculation results with the leaching rate of blank alumina in the same ...

Embodiment 3

[0042] Embodiment 3 (comparative test of embodiment 2):

[0043] Weigh 0.035g of commercially available sodium polyacrylate (PAAS) (0.07% of the amount of clinker) and dissolve it in 200ml of adjusting solution A for leaching clinker to obtain adjusting solution B, add adjusting solution B in a three-necked flask, and place at constant temperature Heat to 80°C in a water bath and keep warm. Weigh 50g of sintered alumina sintered clinker and add it to the adjustment solution B, stir with a polytetrafluoroethylene stirring paddle at a stirring speed of 300r / min, start the leaching timer, and the leaching time is 70min. After leaching, dry filter, accurately weigh the volume of the filtrate, analyze at constant volume, and calculate the leaching rate of alumina. Comparing the calculation results with the leaching rate of blank alumina in the same leaching process without adding inhibitors, it is obtained that the inhibitor increases the leaching rate of alumina, and the leaching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com