Real-time forced belt deviation correcting device

A deviation correction device and belt technology, which is applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of not eliminating the safety risk of belt deviation, scratches, wear and even damage, and belt life reduction, so as to achieve deviation correction Strong strength, high deviation correction strength, and the effect of protecting damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

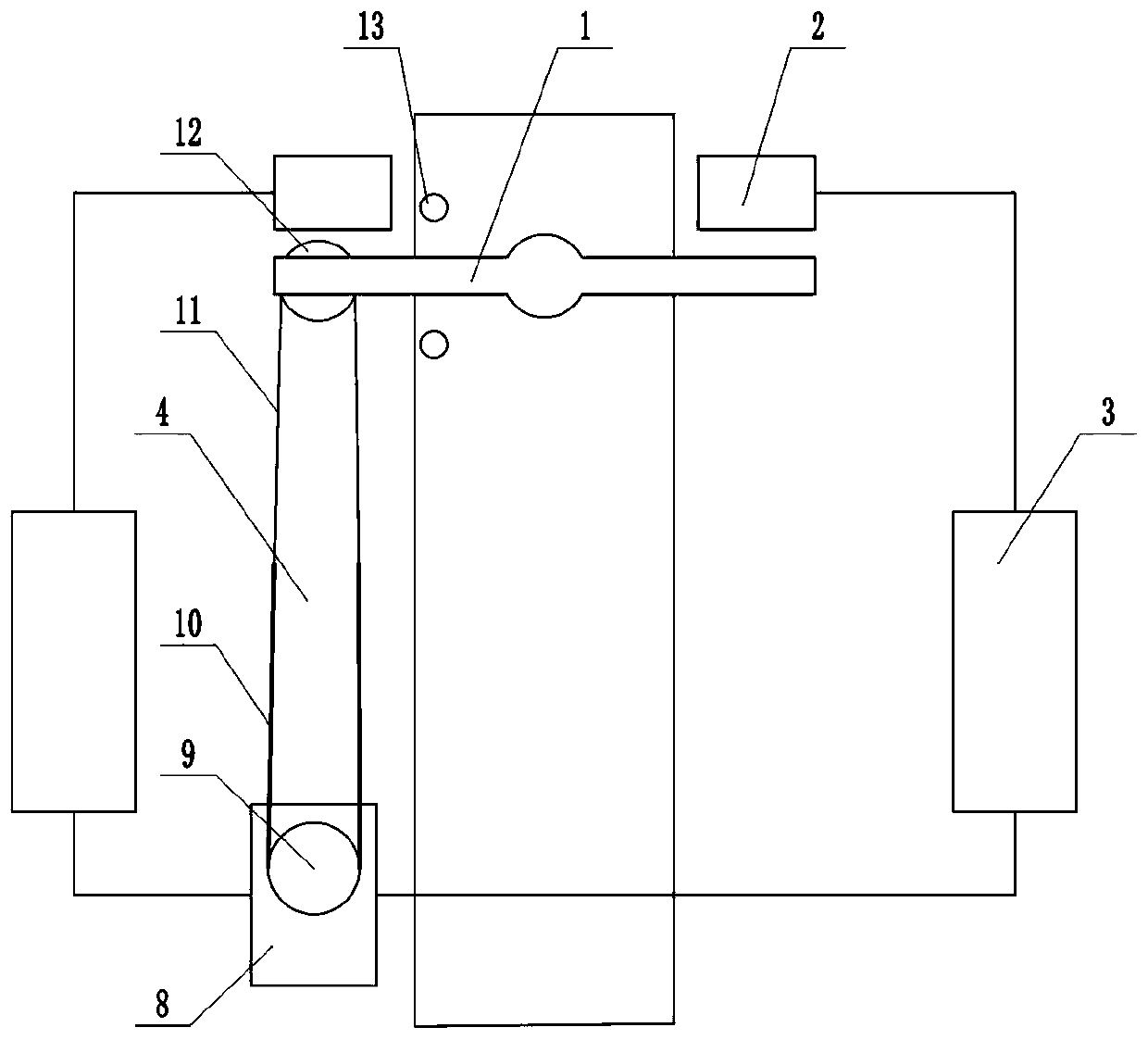

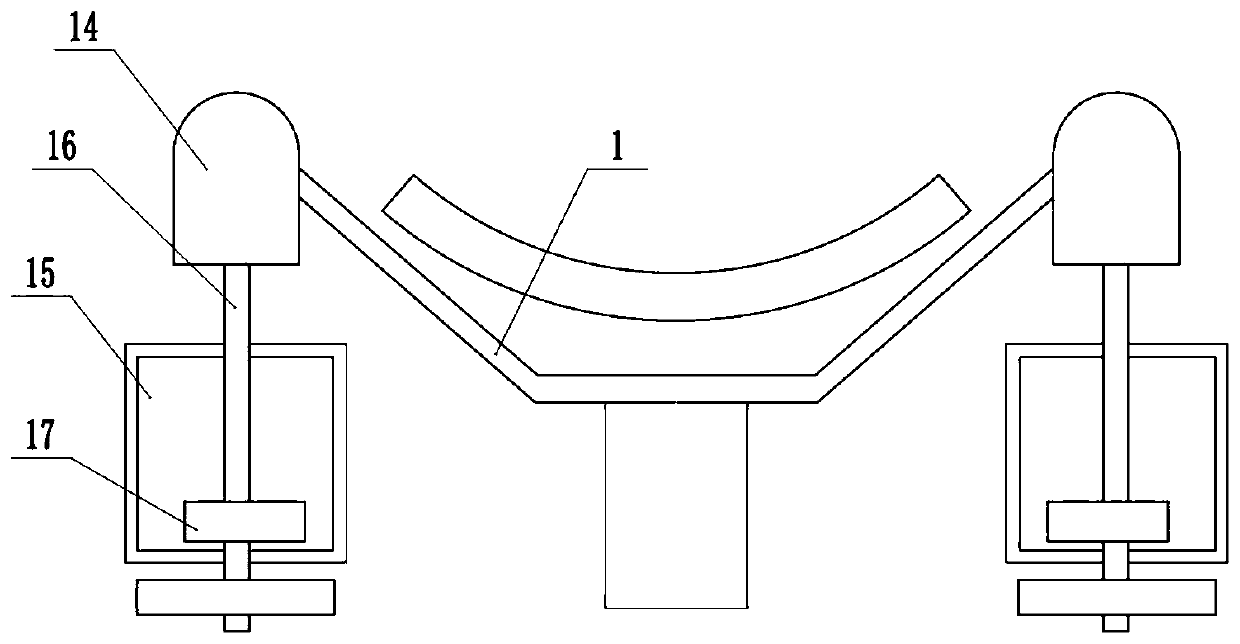

[0024] Please see attached figure 1 to attach image 3 As shown, a real-time forced belt deviation correction device includes a deviation adjustment idler group 1, a trigger mechanism 2, a signal transmission circuit 3 and an actuator 4; the three deviation adjustment idler groups 1 are installed on a belt conveyor, each One trigger mechanism 2 is respectively installed on the left and right sides of the deflection adjustment idler group 1; each trigger mechanism 2 controls the actuator 4 through a signal transmission circuit 3, and the actuator 4 controls the Adjust the movement of idler roller group 1.

[0025] The signal transmission circuit 3 includes a delay switch 5, a time relay 6 and a contactor 7; the trigger mechanism 2 is electrically connected to the input end of the delay switch 5, and the delay switch 5, the time relay 6 and the contactor 7 Electrically connected in turn, the output end of the contactor 7 is electrically connected to the actuator 4 .

[0026] ...

Embodiment 2

[0033] Please see attached figure 1 , attached figure 2 And attached Figure 4 As shown, embodiment 2 is on the basis of embodiment 1, and also includes a signal conversion switch 18 adapted to the oval cam 17; the signal conversion switch 18 is installed in the protective shell 15, and is connected with The two signal transmission circuits 3 are electrically connected.

[0034] How to use: When the working section of the belt conveyor runs towards the head of the belt conveyor, if the belt deviates seriously to the right, first scratch the right side of the belt conveyor as attached figure 1 to attach image 3The vertical rod 14 in the shown signal conversion device drives the vertical rod 16 to turn to the front right through the set angle through the vertical stick 14, and the elliptical cam 17 installed in the vertical rod 16 also turns to the set angle, And trigger the conduction to the right delay switch 5. After the right delay switch 5 receives the current signal,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com