A multi -functional vertical polytetrafluoroethylene board and its layer pressure composite preparation process

A polytetrafluoroethylene sheet, polytetrafluoroethylene technology, which is applied in the directions of lamination, lamination device, lamination auxiliary operation, etc., can solve the problem of poor creep resistance, low bearing capacity, and knotting of polytetrafluoroethylene sealing materials. problems such as low strength, to achieve the effects of good sealing, low preparation cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

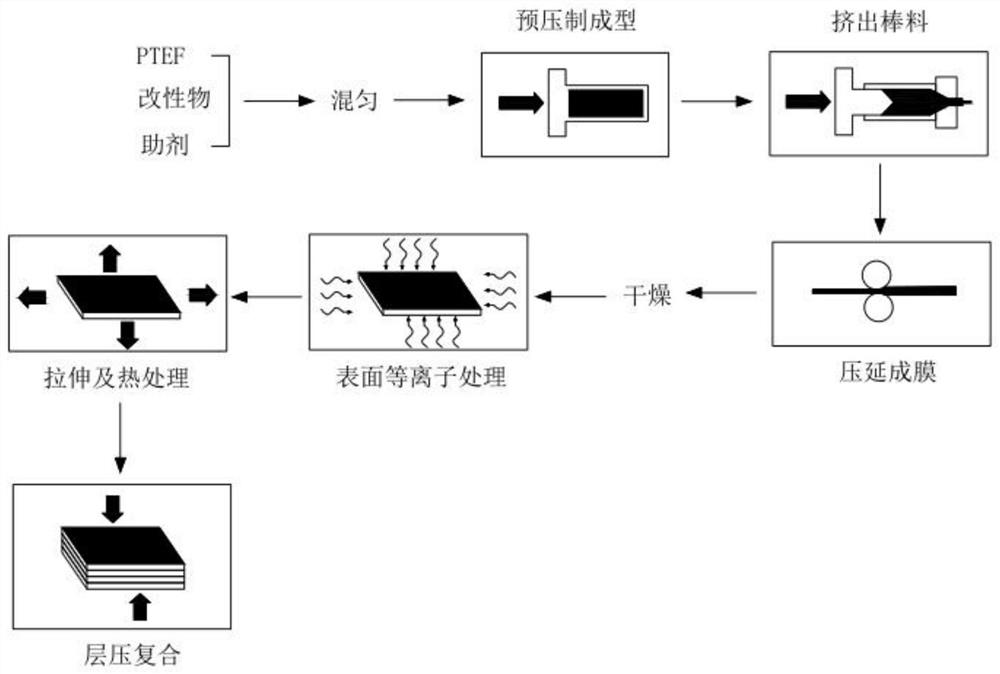

[0036] A multifunctional expanded polytetrafluoroethylene sheet, the polytetrafluoroethylene sheet is made by mixing polytetrafluoroethylene, polyvinylidene fluoride (PVDF), glass fiber, titanium dioxide and solvent oil evenly, pre-pressing and extruding rods after molding , after being pressed into a film by twin-screw, heated and volatilized to remove the solvent oil, and the polytetrafluoroethylene microporous film is obtained by horizontal and vertical stretching, and then the polytetrafluoroethylene microporous film is made into a stretched film by a lamination and composite process. Multifunctional PTFE sheet with high tensile strength.

[0037] The present invention also includes a lamination composite preparation process for preparing the above-mentioned multifunctional expanded polytetrafluoroethylene sheet, comprising the following preparation steps:

[0038] (1) Mixing of raw materials: mechanically mix polytetrafluoroethylene, polyvinylidene fluoride (PVDF), glass ...

Embodiment 2

[0059] The same parts of this embodiment as in Embodiment 1 will not be repeated, and the difference is that the molar ratio of total hydrogen atoms and fluorine atoms in polytetrafluoroethylene and polyvinylidene fluoride is changed to 1:3.

Embodiment 3

[0061] The same parts of this embodiment as in Embodiment 1 will not be repeated, except that the molar ratio of the total hydrogen atoms and fluorine atoms in polytetrafluoroethylene and polyvinylidene fluoride is changed to 1:5.

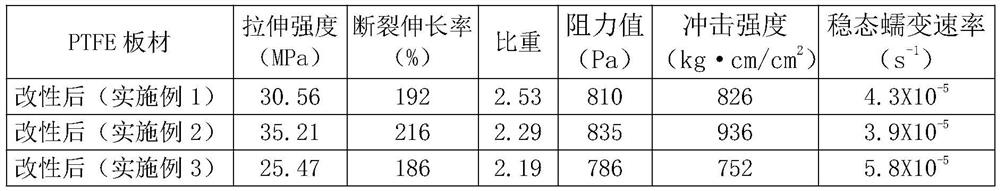

[0062] The test results of the properties of the modified PTFE sheets prepared in Examples 1, 2, and 3 are compared as shown in Table 1 below:

[0063] Comparison of parameters of PTFE sheets in Table 1 Examples 1, 2, and 3

[0064]

[0065] It can be seen from the experimental results that the ratio of hydrogen atoms in the raw material of the PTFE sheet in Example 2 is increased compared to the PTFE sheet in Example 1, and the fibers are protected from more PVDF wrapping to avoid being pulled during the preparation process. Or peel off with PTFE, so the tensile strength, elongation at break, and impact strength of the PTFE sheet prepared in Example 2 are higher than those in Example 1, and the steady-state creep rate decreases; Compared with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com