Truing method and device

A technology for curved parts and decorative strips, which is applied in the field of plastic correction methods and devices, and can solve problems such as plastic correction of unsuitable side decorative strips, appearance of easy-to-damage side decorative strips, poor plasticity of zirconium-based amorphous alloys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a shaping and correction method, which is suitable for the shaping and correction of side decorative strips. It is implemented by a shaping and correction device, which can not only perform shaping and correction on the length of side decorative strips, but also ensure that the performance of side decorative strips remains unchanged. and appearance is not damaged.

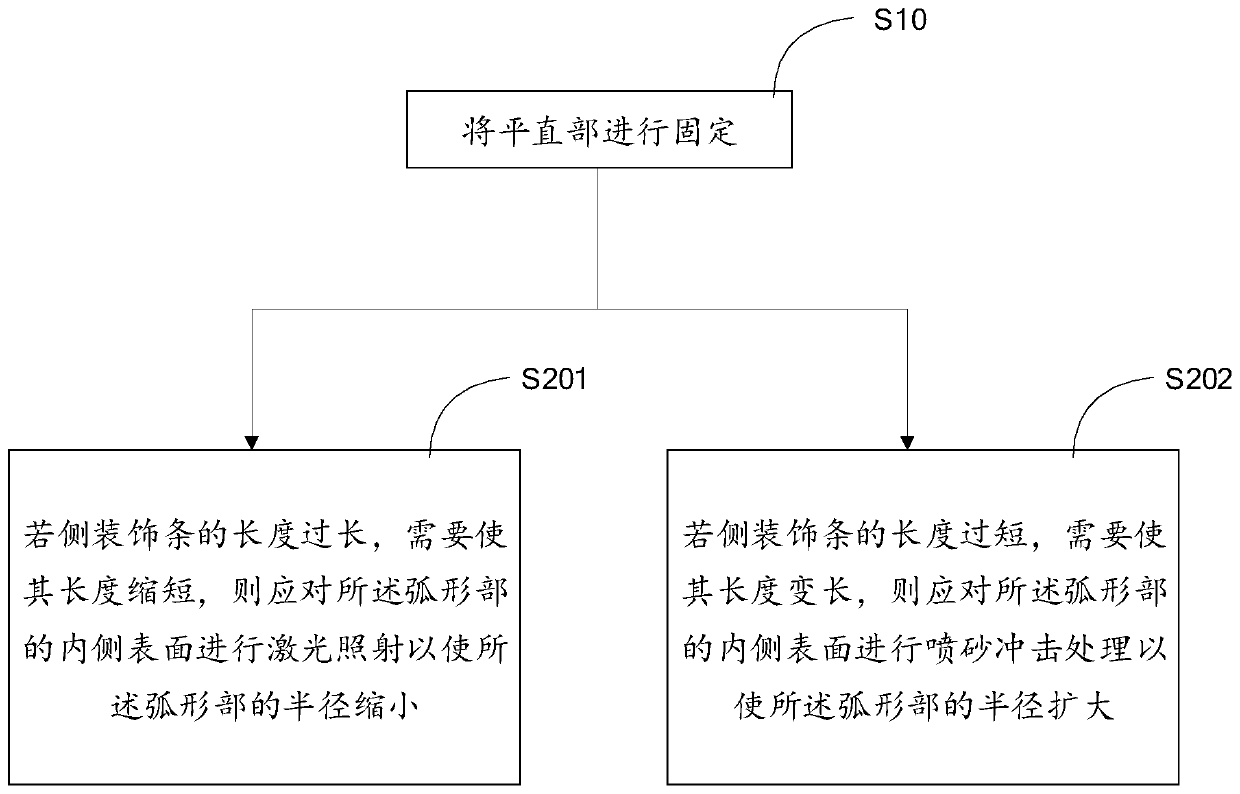

[0041] The side decorative strip includes two arc portions and a straight portion connecting the two arc portions. see figure 2 , the plastic correction method provided in this embodiment includes:

[0042] S10: Fix the straight part.

[0043] S20: Processing the inner surface of the arc portion to change the length of the side decorative strip.

[0044] It should be pointed out that the inner surface of the curved portion will eventually be attached to the housing of an electronic terminal such as a mobile phone, and its main appearance surface is the outer surface.

[0045] It...

Embodiment 2

[0056] The shaping correction device provided in this embodiment can be used to implement the shaping correction method provided in the embodiment of the present invention, and has corresponding functions and beneficial effects.

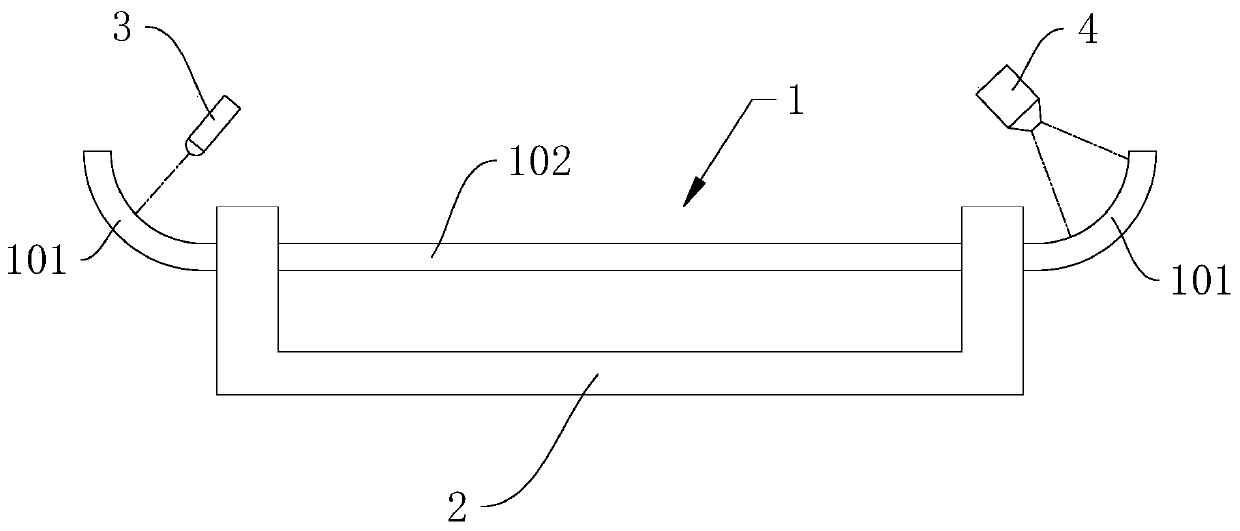

[0057] The shaping correction device is suitable for a side trim strip, and the side trim strip 1 includes two arc portions 101 and a straight portion 102 connecting the two arc portions 101 .

[0058] see image 3 , the plastic correction device includes:

[0059] a fixing jig 2 for fixing the straight portion 102;

[0060] The shaping mechanism is used to process the inner surface of the arc portion 101 to change the length of the side decorative strip 1 .

[0061] Specifically, the shaping mechanism includes:

[0062] A laser emitting mechanism 3, configured to irradiate the inner surface of the arc portion 101 with laser light to reduce the radius of the arc portion 101;

[0063] The laser time control device is used to control the irradiatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com