Stirrer for continuously mixing oily fluid

A stirrer and fluid technology, applied in the direction of mixers, mixer accessories, mixers with rotating stirring devices, etc., can solve the problems of unstable stirring transmission efficiency, uneven mixing of oily fluids, etc., to improve convenience and stability , The effect of double transmission is stable, and the effect of guiding effect is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

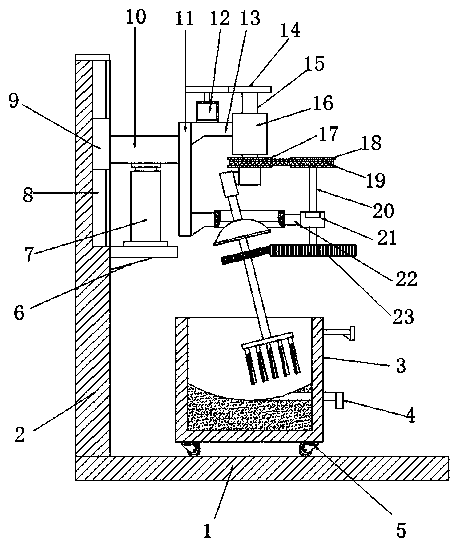

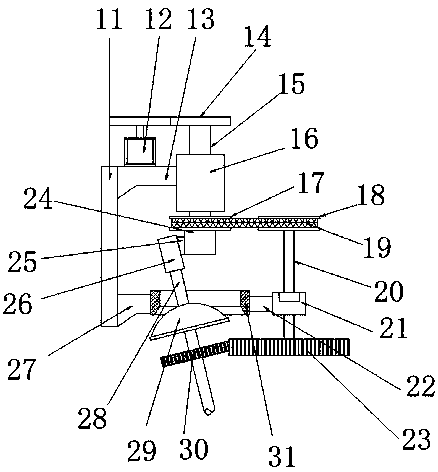

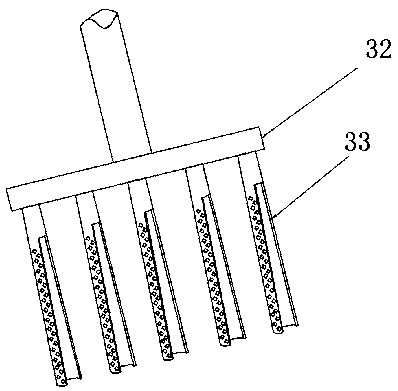

[0028] refer to Figure 1-3 , an agitator for continuous mixing of oily fluids, comprising a bottom plate 1, a side plate 2 is fixed on the left side of the top outer wall of the bottom plate 1, a lifting mechanism is fixed on the outer wall of one side of the side plate 2, and the lifting mechanism is fixedly connected with a connecting plate 11, and the connecting plate 11 One side is fixed with the first connecting block 13 and the second connecting block 27, the first connecting block 13 is fixedly connected with the axle sleeve 16, the rotating shaft 15 is plugged in the axle sleeve 16, the top of the rotating shaft 15 is connected with the drive mechanism, and the rotating shaft 15 bottom ends are fixed with driving block 24, and driving block 24 sides are fixed with wedge-shaped block 25, and the slope of wedge-shaped block 25 is fixed with fixed shaft 26, and the bottom end of fixed shaft 26 is rotated and installed with stirring shaft 28, and the bottom end of stirring...

Embodiment 2

[0036] refer to Figure 4 , an agitator for continuous mixing of oily fluids. The difference between this embodiment and Embodiment 1 is that the moving wheel 5 is replaced by a slider 35, and two slide rails 34 are fixed on the bottom plate 1, and the slider 35 is slidably engaged on the slider. on track 34.

[0037] The working principle of this embodiment: the slide rail 34 can facilitate the lateral movement of the mixing box 3 by using the slider 35, realize the guiding effect of the mixing box 3 moving, and improve the convenience and stability of the mixing box 3 movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com