Probiotic microcapsule with composite material as wall material and preparation method of probiotic microcapsule

A technology of microcapsules and probiotics, applied in the directions of microcapsules, capsule delivery, unknown raw materials, etc., can solve the problems of poor molding stability of microcapsules and difficulty in large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0180] Embodiment 1~5 and corresponding comparative example:

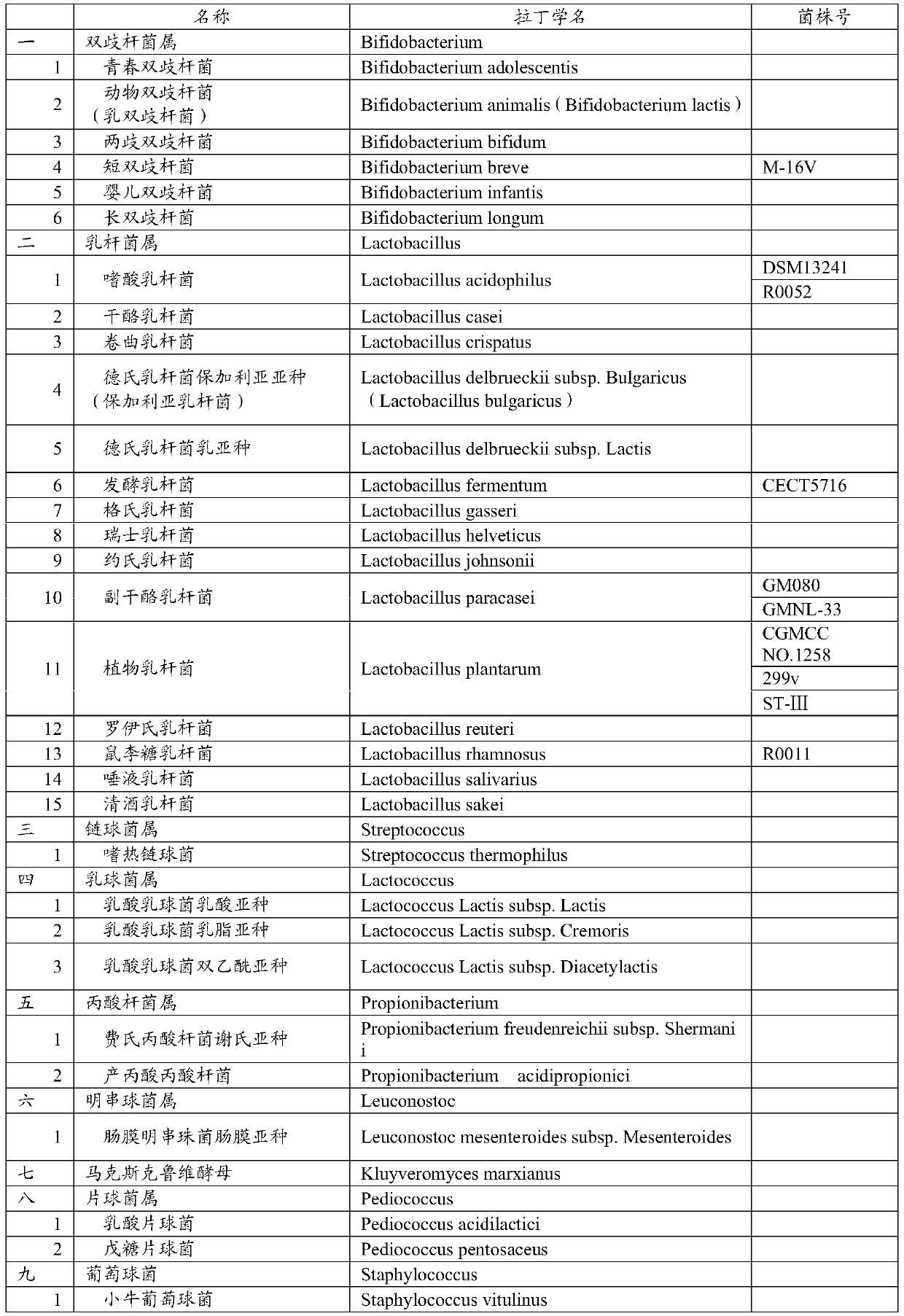

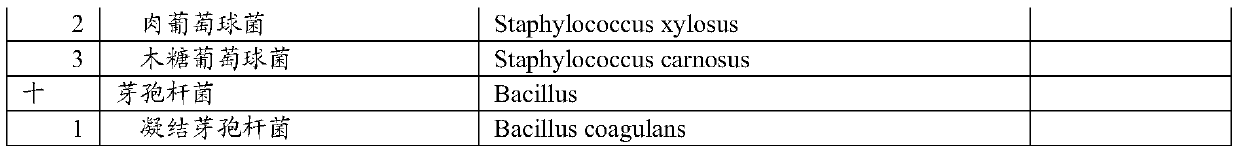

[0181] When preparing the composite wall material, the wall material uses isolated whey protein and pectin. The specific operations of Examples 1-5 and Comparative Examples 1-5 of the present invention are as follows:

Embodiment 1

[0183] Preparation of wall material solution: disperse whey protein isolate in sterile deionized water to prepare a whey protein solution with a mass fraction of 11%, and then add pectin and whey protein isolate dry matter weight ratio of 1:100. Glue, stirred at 4°C for 16 hours at low intensity and constant speed at 180 RPM to fully hydrate the solution until the solution is clear and free of agglomerates. The obtained protein solution was placed in a constant temperature water bath and heated at 78°C, with low-intensity stirring at 95RPM for 45 minutes. Immediately put it into a cold water tank to cool down, store at 4°C for 14 hours for later use, and the obtained wall material solution is obtained.

[0184] Granulation method: at room temperature, use a spray device to spray the above-mentioned wall material suspension containing probiotics through a nozzle with a preferred size of 100 μm, with a preferred frequency of 1000 Hz and a preferred nozzle feed pressure of 800 mb...

Embodiment 2

[0203] Prepare the wall material solution, disperse whey protein isolate in sterile deionized water, prepare a whey protein solution of 11% (w / w), natural pH, and then according to the dry matter mass ratio of pectin and whey protein isolate 1 :200 Add pectin, stir at 4°C for 16 hours at low intensity and constant speed, and rotate at 180RPM, to make it fully hydrated until the solution is clear without agglomeration. The obtained protein solution was placed in a constant temperature water bath and heated at 78°C, with low-intensity stirring at 95RPM for 45 minutes. Immediately put it into a cold water tank to cool down, store at 4°C for 14 hours for later use, and the obtained wall material solution is obtained.

[0204] Granulation method: at room temperature, use a spray device to spray the above-mentioned wall material suspension containing probiotics through a nozzle with a preferred size of 100 μm, with a preferred frequency of 1000 Hz and a preferred nozzle feed pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com