Coal seam roof and floor path virtual planning method for fully mechanized mining equipment space-time kinematics

A technology of roof and floor and kinematics, applied in the fields of earthwork drilling, machine learning, instruments, etc., can solve the lack of overall research on fully mechanized mining equipment and coal seam supporting methods, the lack of fusion of detection data and prediction data of coal seam roof and floor, and the lack of lower circulation Coal seam roof and floor prediction and work path planning to achieve the effect of improving accuracy and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described in more detail below in conjunction with specific embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

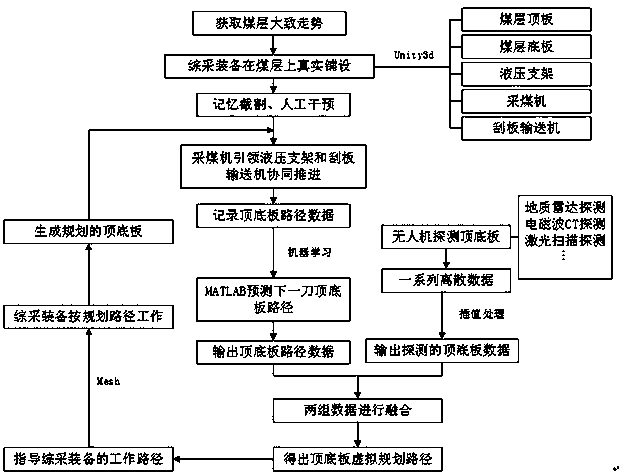

[0035] attached figure 1 It is the main content and flow process of the present invention. The method includes the steps of:

[0036] Detect the outline of the coal seam through geological exploration, obtain the trend and discrete points of the coal seam, interpolate the discrete points, and use Unity3d software to establish the roof and floor of the inherent coal seam;

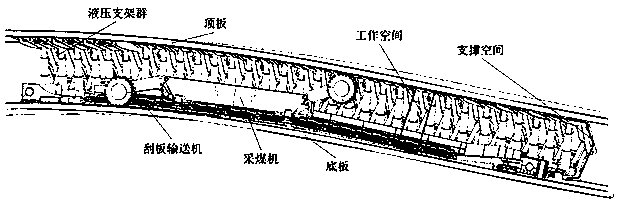

[0037] In Unity3d software, the physical engine is used to realize the real contact between the fully mechanized mining equipment and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com