Treatment method for vintage processing on knitted fabric

A technology for knitted fabrics and processing methods, which is applied in the field of fabric dyeing, can solve the problems of reducing the comfort of knitted fabrics, the surface of knitted fabrics is easily damaged, and the density of knitted fabrics is high, so as to achieve good washing fastness and improve color washing fastness The effect of small loss of strength and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

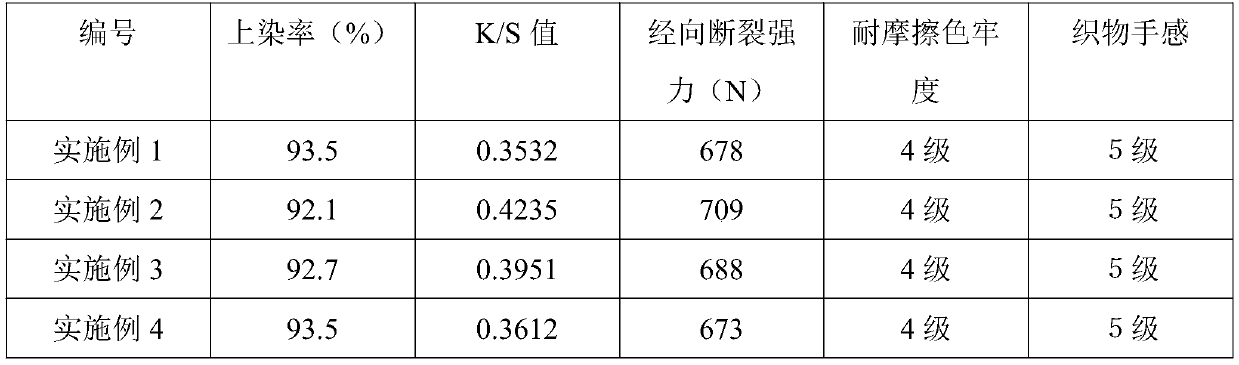

Embodiment 1

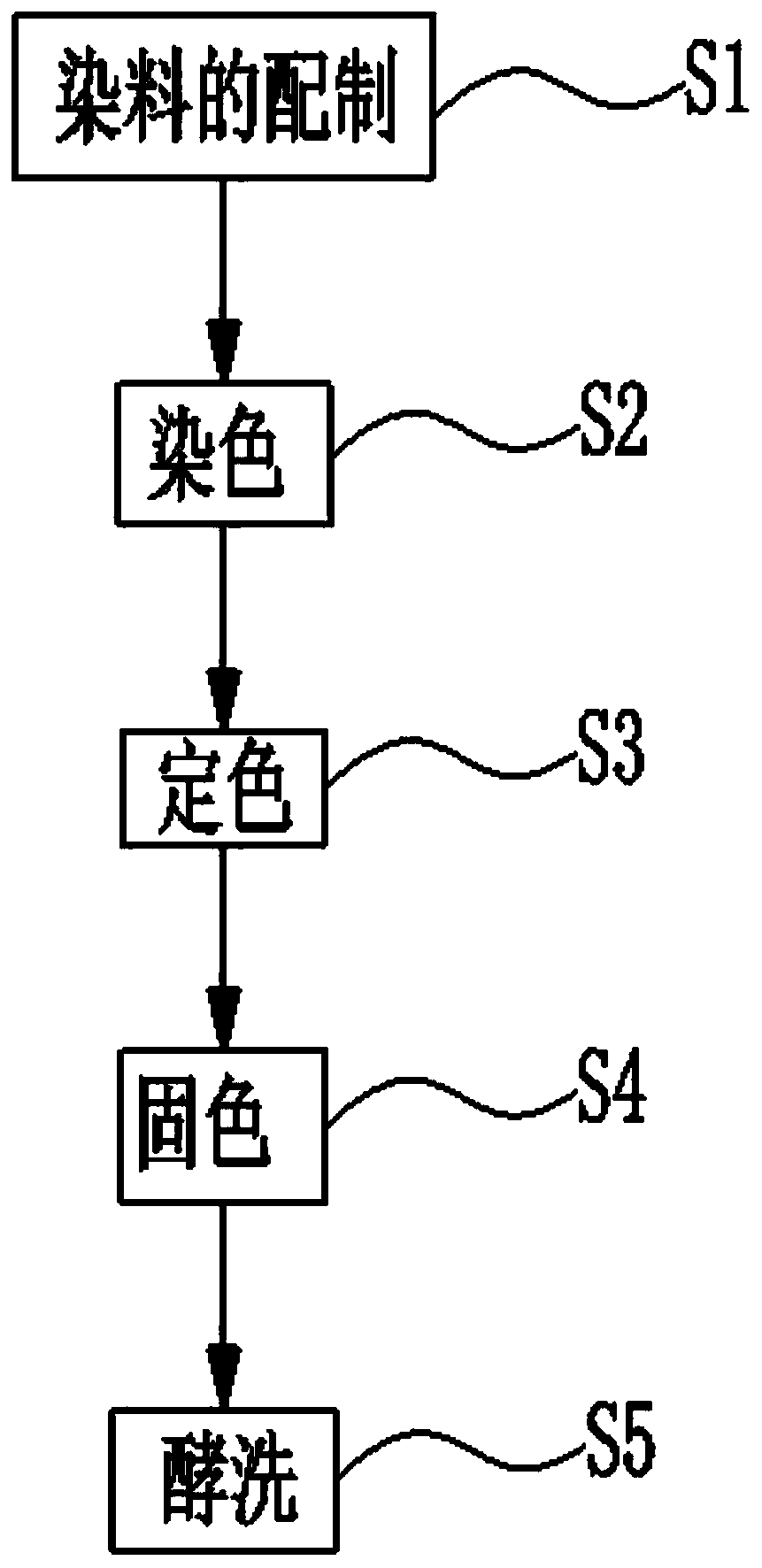

[0058] refer to figure 1 As shown, a method for treating knitted fabrics with retro imitation, specifically includes the following steps:

[0059] S1, the preparation of dyes,

[0060] S11. Accurately weigh 5 kg of weak acid brilliant blue RAW and add it to a stirring tank with 1000 L of water, and stir for 10 minutes;

[0061] S12, then add 2.5kg Yuanming powder and 0.5kg ammonium sulfate, continue to stir for 10min;

[0062] S13, finally add 0.5kg fatty alcohol polyoxyethylene ether and 1.5kg glacial acetic acid, continue stirring for 10min;

[0063] S14. Then, at a heating rate of 1.5° C. / min, the mixed solution is heated from room temperature to 100° C., and kept at a temperature of 100° C. for 40 minutes;

[0064] S15. Naturally cool to room temperature and set aside.

[0065] S2, dyeing,

[0066] S21, put the knitted fabric fabric into the air overflow dyeing machine;

[0067] S22. Preheat the dye prepared in step S1 to 50° C., then add it to the air overflow dyein...

Embodiment 2

[0083] In step S1, accurately weigh 3kg of weak acid brilliant blue RAW and add it to a stirring tank with 1000L of water, and stir for 10 minutes; Oxyethylene ether and 1kg glacial acetic acid continued to stir for 10min; all the other technical features were the same as in Example 1.

Embodiment 3

[0085] In step S1, accurately weigh 4 kg of weak acid brilliant blue RAW and add it to a stirring tank with 1000 L of water, and stir for 10 min; then add 2 kg of sodium bicarbonate and 0.6 kg of ammonium sulfate, and continue stirring for 10 min; finally add 0.5 kg of fatty alcohol polyoxygen Vinyl ether and 1.2kg glacial acetic acid continued to stir for 10 min; all the other technical features were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com