Economical low-temperature structural steel plate for polar region and manufacturing method thereof

A technology for structural steel plates and manufacturing methods, which is applied in the field of economical low-temperature structural steel plates for polar regions and its manufacturing, can solve the problems of steel plate performance fluctuations, increased control difficulty, increased production costs, etc., achieve low-temperature toughness improvement, increase crack growth resistance, The effect of reducing the amount added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

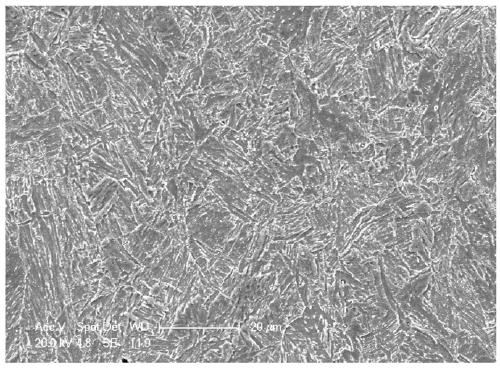

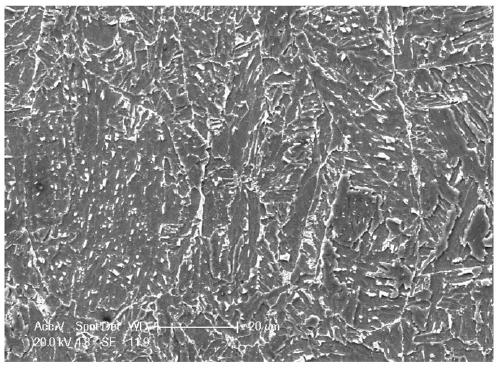

Embodiment 1

[0023] According to chemical composition: C: 0.09%, Si: 0.34%, Mn: 1.37%, Nb: 0.045%, V: 0.038%, Ti0.018%, Als: 0.042%, Ni: 0.36%, P: 0.009%, S : 0.002%, CEV: 0.35%, the rest is Fe and unavoidable impurities smelted continuous casting slab. The cross-sectional size of the continuous casting slab obtained from the molten steel with qualified composition is 300×1820mm; after the hot continuous casting slab is cut into a fixed length, it is hoisted and stacked at a temperature of 750-700°C and slowly cooled for more than 3 days. The continuous casting slab is reheated, and the furnace time is controlled at 4.5 hours, and the furnace temperature is 1175°C. After coming out of the furnace, descale and enter the roughing mill for rolling. Rolling starts at 1056°C. The reduction ratios of the last two passes of this stage are controlled at 18.2 and 18.6% respectively, and the final final rolling temperature is guaranteed to be 1005°C. At this time, the rolling The thickness is 160mm...

Embodiment 2

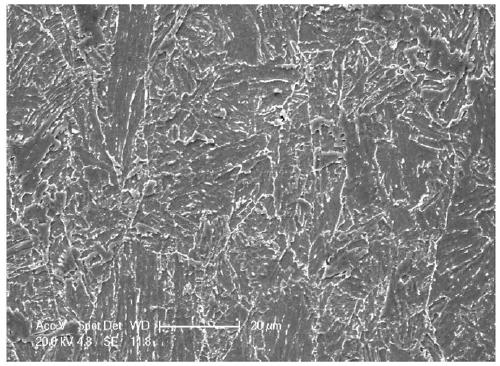

[0025]According to chemical composition: C: 0.05%, Si: 0.17%, Mn: 1.28%, Nb: 0.026%, V: 0.024%, Ti0.022%, Als: 0.030%, Ni: 0.21%, P: 0.008%, S : 0.001%, CEV: 0.28%, the rest is Fe and unavoidable impurities smelted continuous casting slab. The cross-sectional size of the continuous casting slab obtained from molten steel with qualified composition is 250×2320mm; after the hot continuous casting slab is cut into a fixed length, it is hoisted and stacked at a temperature of 650-600°C and slowly cooled for more than 3 days. The continuous casting slab is reheated, and the furnace time is controlled for 4 hours, and the furnace temperature is 1145°C. After coming out of the furnace, descale and enter the roughing mill for rolling. The rolling starts at 1047°C. The reduction ratios of the last two passes of this stage are controlled at 16.7 and 17.1% respectively, and the final final rolling temperature is guaranteed to be 995°C. At this time, the rolled piece The thickness is 130...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com