Chromium-containing waste leather scrap treatment method

A treatment method and dander technology, which is applied in the field of chromium-containing waste dander treatment, can solve problems such as waste of resources and environmental hazards, achieve mild hydrolysis, ensure stability, and ensure the effect of hydrolysis quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

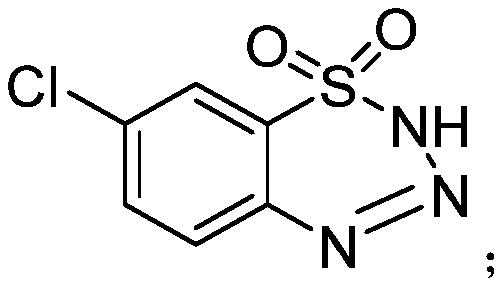

[0026] The preparation method of 7-chloro-2H-benzo[e][1,2,3,4]thitriazine 1,1-dioxide is:

[0027] 2mmol 2-amino-5-chlorobenzenesulfonamide, 3mmol tert-butyl nitrite and 20ml solvent acetonitrile were added to the reaction vessel, stirred and mixed, and the reaction was carried out at a temperature of 25°C after mixing evenly, and the reaction time was 2h; After completion, filter and purify to obtain 7-chloro-2H-benzo[e][1,2,3,4]thitriazine 1,1-dioxide; the product yield is 90%.

[0028] Its reaction formula is

[0029]

[0030] Characterization data

[0031] 1 H NMR (400MHz, CDCl 3 )δ8.11(s,1H),7.64-7.61(m,1H),7.37-7.34(m,1H),7.18(s,1H); 13 C NMR (100MHz, CDCl 3 )δ145.2,132.2,131.8,130.9,126.3,121.7.

Embodiment 2

[0033] A method for treating chrome-containing waste dander, comprising the following steps: the addition of additives in each operation is based on the quality of chrome-containing waste dander:

[0034] Step 1: Add chrome-containing waste dander and 150% deionized water into the reaction vessel, stir and mix, after mixing evenly, add 5% protease into the reaction vessel for the first hydrolysis at a temperature of 37°C processing, the processing time is 4h;

[0035] Step 2: add 20% acid solution into the reaction vessel for stirring and mixing, and form a mixed solution after mixing evenly; under the condition of a temperature of 45°C, carry out the second hydrolysis treatment, and the treatment time is 5h;

[0036] Step 3: Adjust the pH of the mixture to 5.0-6.0 with an aqueous sodium carbonate solution with a mass concentration of 15%; then add 3% modifier, 1% accelerator, 2% dispersant and 0.5% catalyst to the mixture and stir After mixing, the retanning filler was prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com