Mixed bacteria secondary fermentation technology and application thereof in industrial production of L-alanine

A secondary fermentation, alanine technology, applied in fermentation, microorganism-based methods, microorganisms, etc., can solve problems such as limitations, inability to dock industrialization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

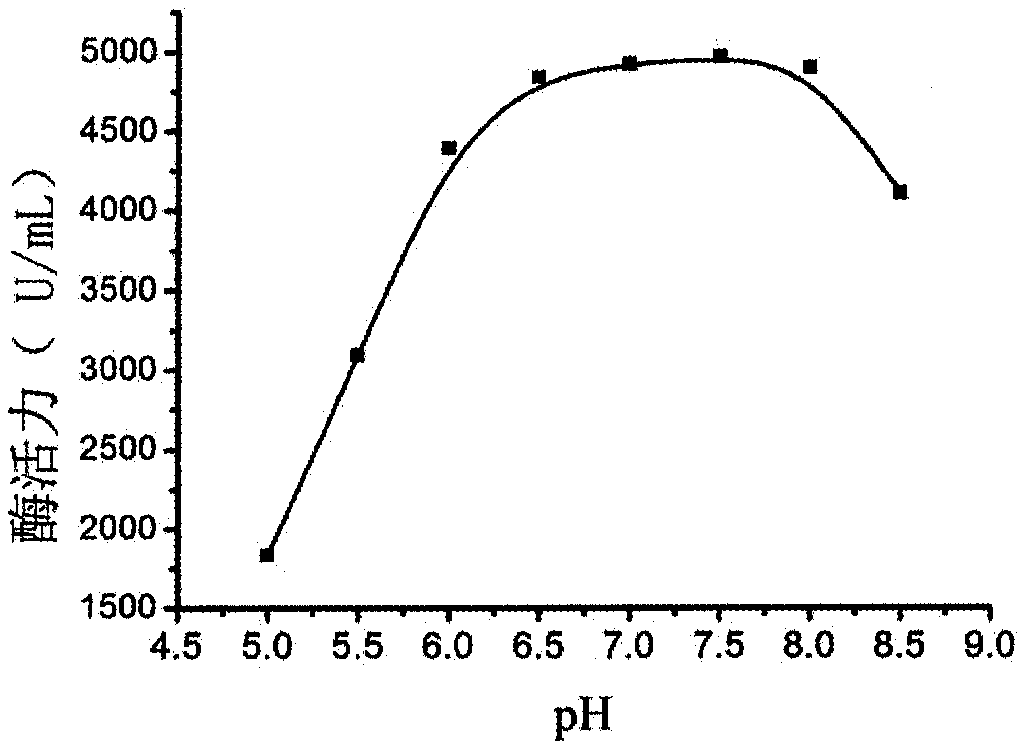

[0010] Embodiment 1 L-aspartase catalyzed pH range

[0011] The strain Escherichia coli CGMCC 9850 obtained by the previous screening and mutagenesis was fermented and cultured, and the fermentation medium was (g / L): corn steep liquor dry powder 13.0, magnesium sulfate 0.2, potassium dihydrogen phosphate 1.0, sodium chloride 1.5, fumaric acid 5.0, glucose 5.0, and ammonia water to adjust the pH to 6.5-7.0, collect the fermentation broth, and measure the enzyme activity under the conditions of pH 5.5, 6.0, 6.5, 7.0, 7.5, 8.0, and 8.5, and the results are shown in the attached figure 1 As shown, according to the measured enzyme activity and the corresponding pH value, the fitting curve is drawn, and it can be seen that within the pH range of 6.0-8.0, there is no significant difference in the L-aspartase activity of Escherichia coli CGMCC 9850, and the pH range Synchronized with Comamonas testosteroni CGMCC 6083, laying the foundation for mixed fermentation and joint catalysis. ...

Embodiment 2

[0012] Embodiment 2 fermentation medium optimization

[0013] Select the key factors of fermentation, carbon source, nitrogen source and inducer, and use single factor analysis combined with orthogonal experiment method to screen glucose, sucrose, citric acid, fumaric acid, glutamic acid, peptone, beef extract, corn steep liquor dry powder, yeast Flour, hydrolyzed cottonseed protein and other carbon sources, nitrogen sources and inducers were comprehensively evaluated by bacterial growth and enzyme activity. The results showed that the best nitrogen sources were peptone and corn steep liquor powder, and the best carbon sources were sodium glutamate and rich For malic acid, further optimize the concentration to obtain a primary fermentation medium formula range (g / L): peptone 5-10, corn steep liquor powder 10-20, sodium glutamate 6-10, magnesium sulfate 0.1-0.3, dihydrogen phosphate Potassium 0.5-1.5, the pH is adjusted to 6.5-7.5 with NaOH, the final concentration of the secon...

Embodiment 3

[0014] Embodiment 3 50L tank fermentation and 20t tank fermentation

[0015] Pilot and trial production were carried out in 50L and 20t fermenters with the above-mentioned optimized optimal medium, and secondary fermentation was carried out in stages. Comamonas testosteroni CGMCC 6083 was fermented once, and Escherichia coli CGMCC 9850 was inoculated after culturing at 36°C for 8 hours. The fermentation was continued for 12 hours. At the end of the fermentation, the vigor of the two strains was the highest, reaching above 26000U / mL and 4900U / mL respectively. Since the activity of L-aspartic acid enzyme is high enough, and it is the rate-limiting step of co-production, although the activity of L-aspartic acid-β-decarboxylase in mixed-bacteria fermentation is slightly lower than that of single-bacteria fermentation, it has no effect on production efficiency. influences.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com