Up-conversion nanometer material with greatly enhanced red light and preparation method thereof

A nanomaterial, red light technology, applied in luminescent materials, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as the decline of luminous efficiency, and achieve the effect of eliminating surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

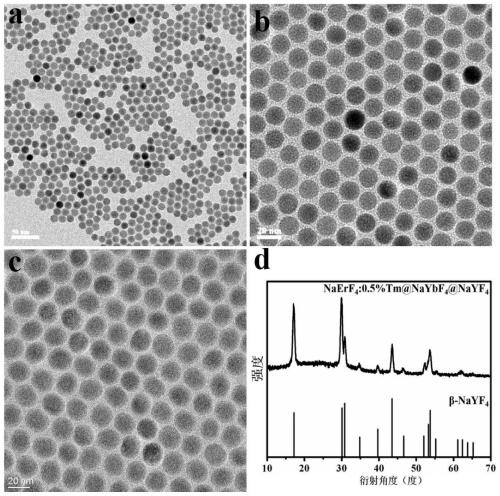

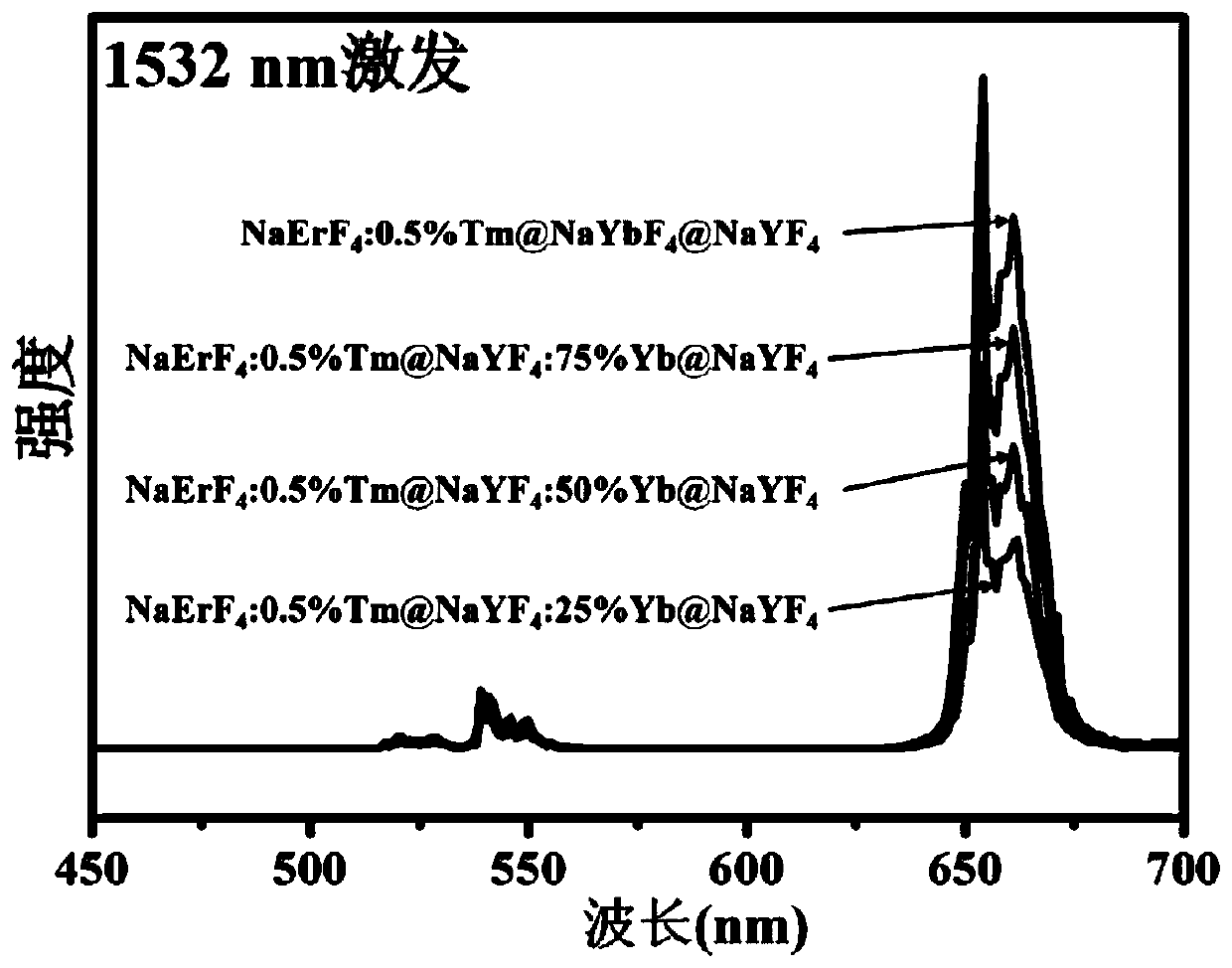

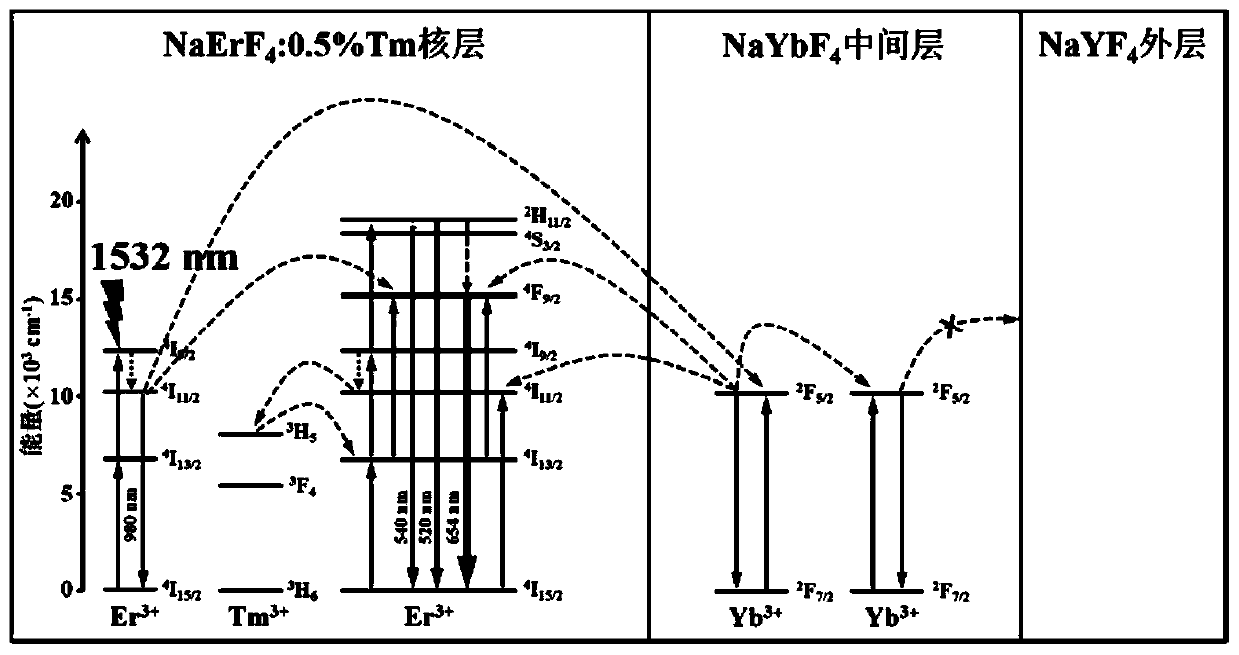

[0063] This embodiment provides a kind of NaErF 4 :0.5%Tm@NaYF 4 :25%Yb@NaYF 4 Preparation methods of upconversion nanomaterials.

[0064] (1)NaErF 4 : 0.5% Tm core layer preparation: put 6mL oleic acid and 15mL octadecene into a 100mL three-necked flask, mix and stir evenly. Then add 0.995mL concentration of 1mol L -1 Erbium chloride solution and 0.05mL concentration of 0.1mol L -1 Thulium chloride solution, mixed and stirred evenly, then heated up to 105°C and kept for 30min to remove water. Then the temperature was raised to 150°C and kept for 30 minutes to generate a rare earth-oleic acid chelate. Then the temperature was naturally cooled to room temperature, 0.1 g of sodium hydroxide (2.5 mmol) and 0.148 g of ammonium fluoride (4 mmol) in methanol (10 mL in total) were added to the above mixture and stirred, then the temperature was raised to 75 ° C and kept for 45 min , to remove excess methanol. Then, under the protection of argon, the temperature was raised to ...

Embodiment 2

[0068] This embodiment provides a kind of NaErF 4 :0.5%Tm@NaYF 4 :50%Yb@NaYF 4 Preparation methods of upconversion nanomaterials.

[0069] (1)NaErF 4 : 0.5% Tm core layer preparation: put 6mL oleic acid and 15mL octadecene into a 100mL three-necked flask, mix and stir evenly. Then add 0.995mL concentration of 1mol L -1 of erbium chloride solution and 0.05mL with a concentration of 0.1mol L -1 Thulium chloride solution, mixed and stirred evenly, then heated up to 105°C and kept for 30min to remove water. Then the temperature was raised to 150°C and kept for 30 minutes to generate a rare earth-oleic acid chelate. Then the temperature was naturally cooled to room temperature, 0.1 g of sodium hydroxide (2.5 mmol) and 0.148 g of ammonium fluoride (4 mmol) in methanol (10 mL in total) were added to the above mixture and stirred, then the temperature was raised to 75 ° C and kept for 45 min , to remove excess methanol. Then, under the protection of argon, the temperature was ...

Embodiment 3

[0073] This embodiment provides a kind of NaErF 4 :0.5%Tm@NaYF 4 :75%Yb@NaYF 4 Preparation methods of upconversion nanomaterials.

[0074] (1)NaErF 4 : 0.5% Tm core layer preparation: put 6mL oleic acid and 15mL octadecene into a 100mL three-necked flask, mix and stir evenly. Then add 0.995mL concentration of 1mol L -1 Erbium chloride solution and 0.05mL concentration of 0.1mol L -1 Thulium chloride solution, mixed and stirred evenly, then heated up to 105°C and kept for 30min to remove water. Then the temperature was raised to 150°C and kept for 30 minutes to generate a rare earth-oleic acid chelate. Then the temperature was naturally cooled to room temperature, 0.1 g of sodium hydroxide (2.5 mmol) and 0.148 g of ammonium fluoride (4 mmol) in methanol (10 mL in total) were added to the above mixture and stirred, then the temperature was raised to 75 ° C and kept for 45 min , to remove excess methanol. Then, under the protection of argon, the temperature was raised to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com