Manually carved model epoxy resin mud and preparation method thereof

An epoxy resin and model technology, which is applied to the field of hand-carved model epoxy resin clay and its preparation, can solve the problems of reducing the curing effect and physical and chemical properties of modeling materials, losing the effect of modeling art performance, and the stickiness of carving tools being outstanding. To achieve excellent performance of hand engraving with water, strong expressiveness of engraving details, good self-adhesion and repairability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

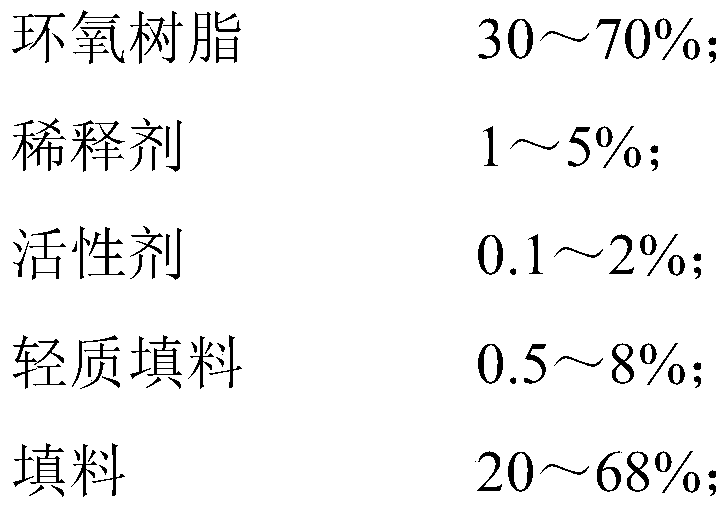

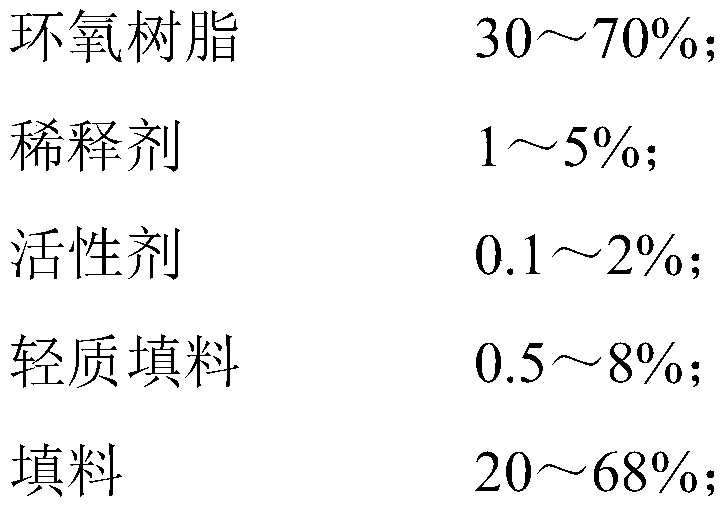

Method used

Image

Examples

Embodiment 1

[0040] Component A: The epoxy resin is bisphenol A epoxy resin, the diluent is butyl glycidyl ether, the active agent is a wetting and dispersing agent containing phosphine-sulfonic acid copolymer, and the lightweight filler is hollow glass microspheres. The filler is phenolic resin microspheres and heavy calcium;

[0041] Component B: The curing agent is aliphatic amine room temperature curing agent, the thixotropic agent is fumed silica, the flame retardant is aluminum hydroxide, the pigment is pigment carbon black, and the filler is talcum powder.

Embodiment 2

[0043]Component A: The epoxy resin is hydrogenated epoxy resin, the diluent is allyl glycidyl ether, the active agent is polyammonium ammonium carboxylate sodium wetting and dispersing agent, the lightweight filler is hollow glass microspheres and diatomaceous earth, the filler phenolic resin microspheres;

[0044] Component B: the curing agent is aliphatic amine curing agent at room temperature, the active agent can be the same as that of component A, the thixotropic agent is organic bentonite, the flame retardant is magnesium hydroxide and aluminum hydroxide, the pigment is yellow toner and blue Color powder, the filler is kaolin.

Embodiment 3

[0046] Component A: The epoxy resin is bisphenol A epoxy resin, the diluent is lauryl glycidyl ether, the active agent is a wetting and dispersing agent containing phosphine sulfonic acid copolymer and anilinomethyltriethoxy Silane, light filler is diatomaceous earth, filler is phenolic resin microspheres and whiskers.

[0047] Component B: the curing agent is aliphatic amine curing agent at room temperature, the active agent can be the same as that of component A, the thixotropic agent is organic bentonite, the flame retardant is antimony trioxide, the pigment is brown toner, and the filler is mica powder .

[0048] The present invention provides hand-engravable model epoxy resin mud, which mainly includes the following steps:

[0049] Preparation of component A: Add epoxy resin, diluent and active agent into a vacuum mixer, stir at a speed of 1000rpm for 10 minutes, then reduce the speed to 500rpm, and add light filler and filler in sequence. After all was added, the speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com