Preparation method of foamed floating ball

A floating ball and foaming agent technology, applied in the field of foamed plastics, can solve problems affecting the accuracy of liquid level detection, uneven foaming of floating balls, rough outer surface, etc., achieve long service life, improve thermal stability, The effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

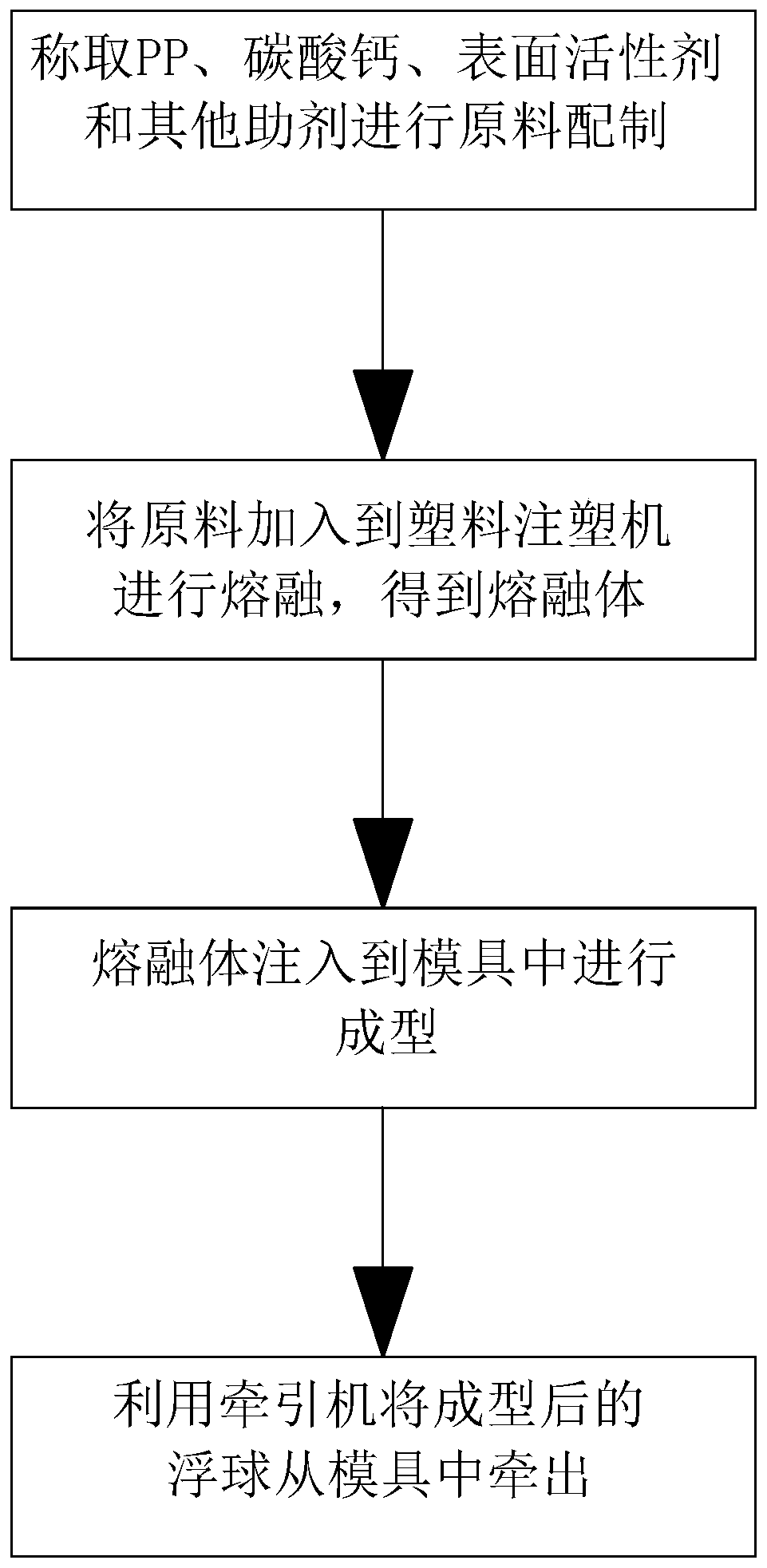

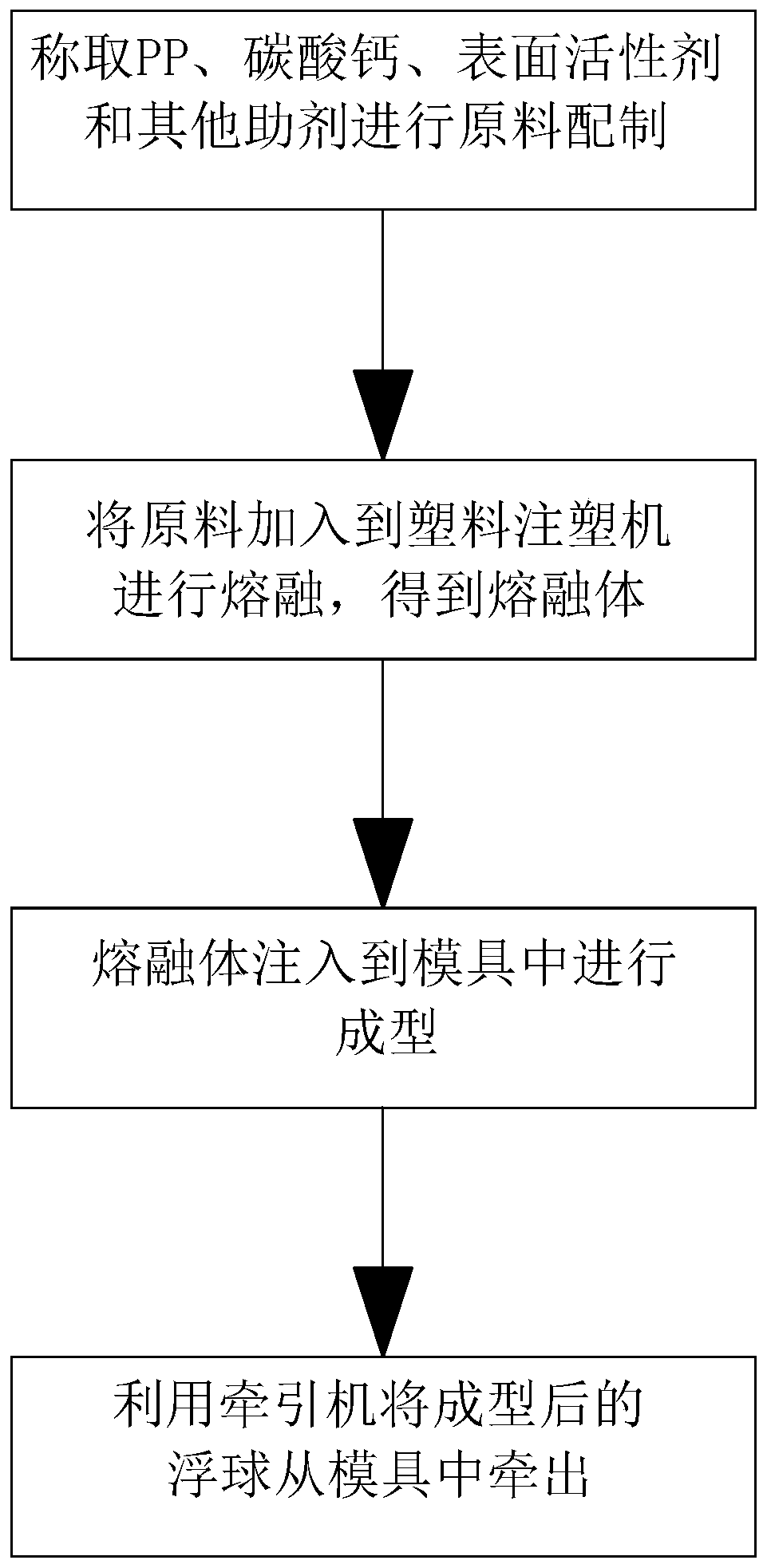

[0036] A preparation method for foamed buoyant balls, comprising the steps of,

[0037] Step 1, take 75KgPP, 3Kg calcium carbonate, 2Kg sodium dodecylbenzenesulfonate, 11Kg other additives and prepare raw materials;

[0038] Step 2, adding the raw materials of step 1 to a plastic injection molding machine for heating and melting to obtain a molten body;

[0039] Step 3, injecting the molten body of step 2 into a mold for molding;

[0040] Step 4. Use the tractor to pull the formed floating ball out of the mold.

[0041] Wherein, the plastic injection molding machine in step 2 is heated by microwaves with a frequency of 5400 MHz generated by a microwave generator. And other additives are the anti-oxidant of the white oil of 4Kg, the lithium iodide of 4Kg and 3Kg. Here, the antioxidant is a mixture of N-phenyl-α-naphthylamine and benzofuranone, and the mass ratio of N-phenyl-α-naphthylamine and benzofuranone is 1:1. In addition, calcium carbonate was soaked in acrylic acid f...

Embodiment 2

[0043] A preparation method for foamed buoyant balls, comprising the steps of,

[0044] Step 1, take by weighing 80KgPP, 6Kg magnesium carbonate, 3Kg potassium lauryl phosphate and 13Kg other auxiliary agents to prepare raw materials;

[0045] Step 2, adding the raw materials of step 1 to a plastic injection molding machine for heating and melting to obtain a molten body;

[0046] Step 3, injecting the molten body of step 2 into a mold for molding;

[0047] Step 4. Use the tractor to pull the formed floating ball out of the mold.

[0048] Wherein, the plastic injection molding machine in step 2 is heated by microwaves with a frequency of 6800 MHz generated by a microwave generator. And other additives are 5Kg white oil, 4.5Kg cuprous iodide and 3.5Kg antioxidant. Here, the antioxidant is a mixture of N-phenyl-α-naphthylamine and benzofuranone, and the mass ratio of N-phenyl-α-naphthylamine and benzofuranone is 1:1. In addition, magnesium carbonate was soaked in maleic acid...

Embodiment 3

[0050] A preparation method for foamed buoyant balls, comprising the steps of,

[0051] Step 1, take by weighing 85KgPP, 9Kg sodium bicarbonate, 4Kg sodium dodecylbenzenesulfonate and 15Kg other auxiliary agents to prepare raw materials;

[0052] Step 2, adding the raw materials of step 1 to a plastic injection molding machine for heating and melting to obtain a molten body;

[0053] Step 3, injecting the molten body of step 2 into a mold for molding;

[0054] Step 4. Use the tractor to pull the formed floating ball out of the mold.

[0055]Wherein, the plastic injection molding machine in step 2 is heated by microwaves with a frequency of 8200 MHz generated by a microwave generator. And other additives are the anti-oxidant of the white oil of 6Kg, the lithium iodide of 5Kg and 4Kg. Here, the antioxidant is a mixture of N-phenyl-α-naphthylamine and benzofuranone, and the mass ratio of N-phenyl-α-naphthylamine and benzofuranone is 1:1. In addition, sodium bicarbonate was so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com