Preparation method and application of magnetic sulfonated polystyrene molecular brush

A technology of polystyrene and molecular brushes, which is applied in the preparation of organic compounds, chemical instruments and methods, and the preparation of aminohydroxyl compounds, etc., can solve problems such as increased production costs, low sulfonic acid group loading, and difficulty in recycling, and achieve reduction Effects of pollutant discharge, simplified post-treatment, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

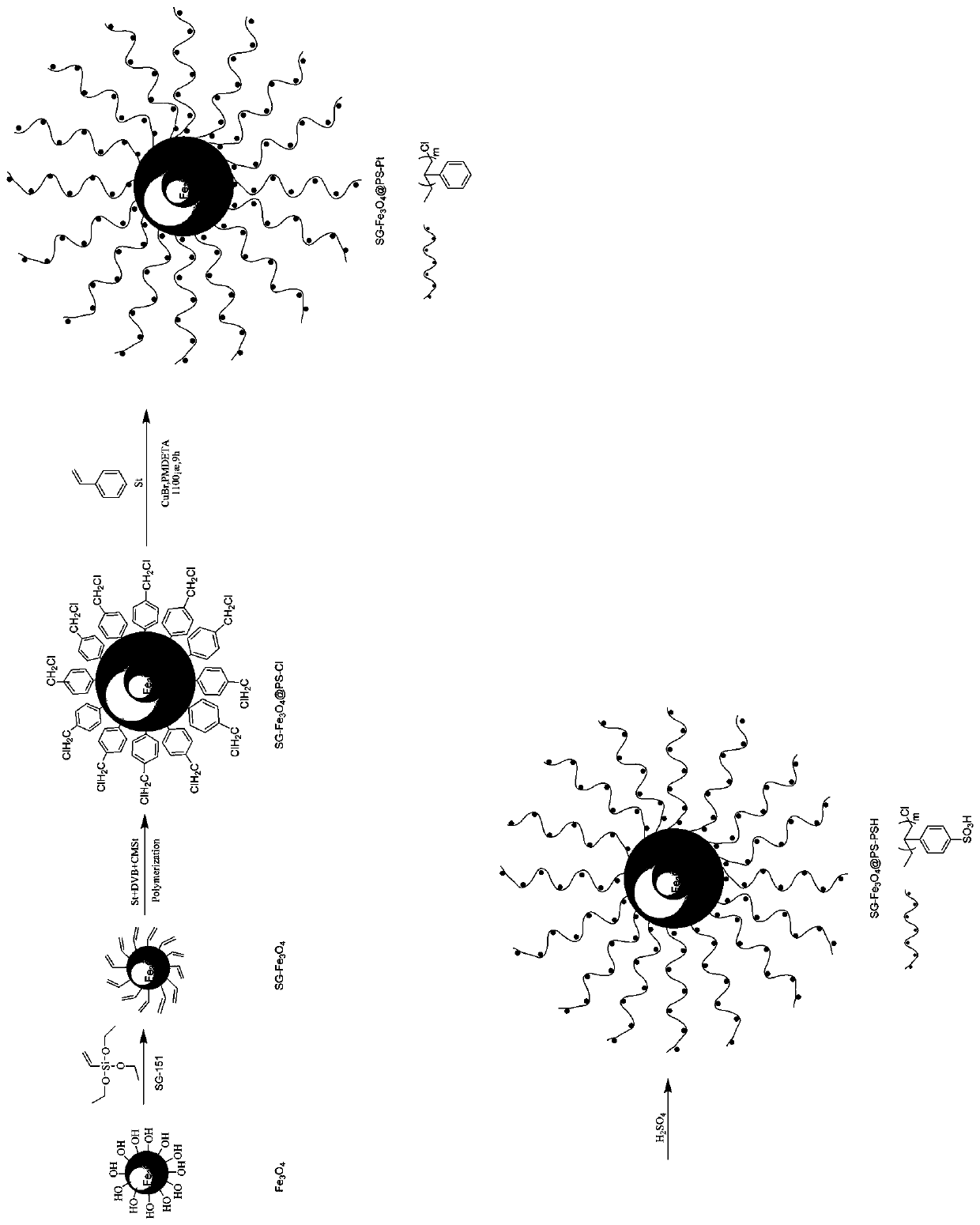

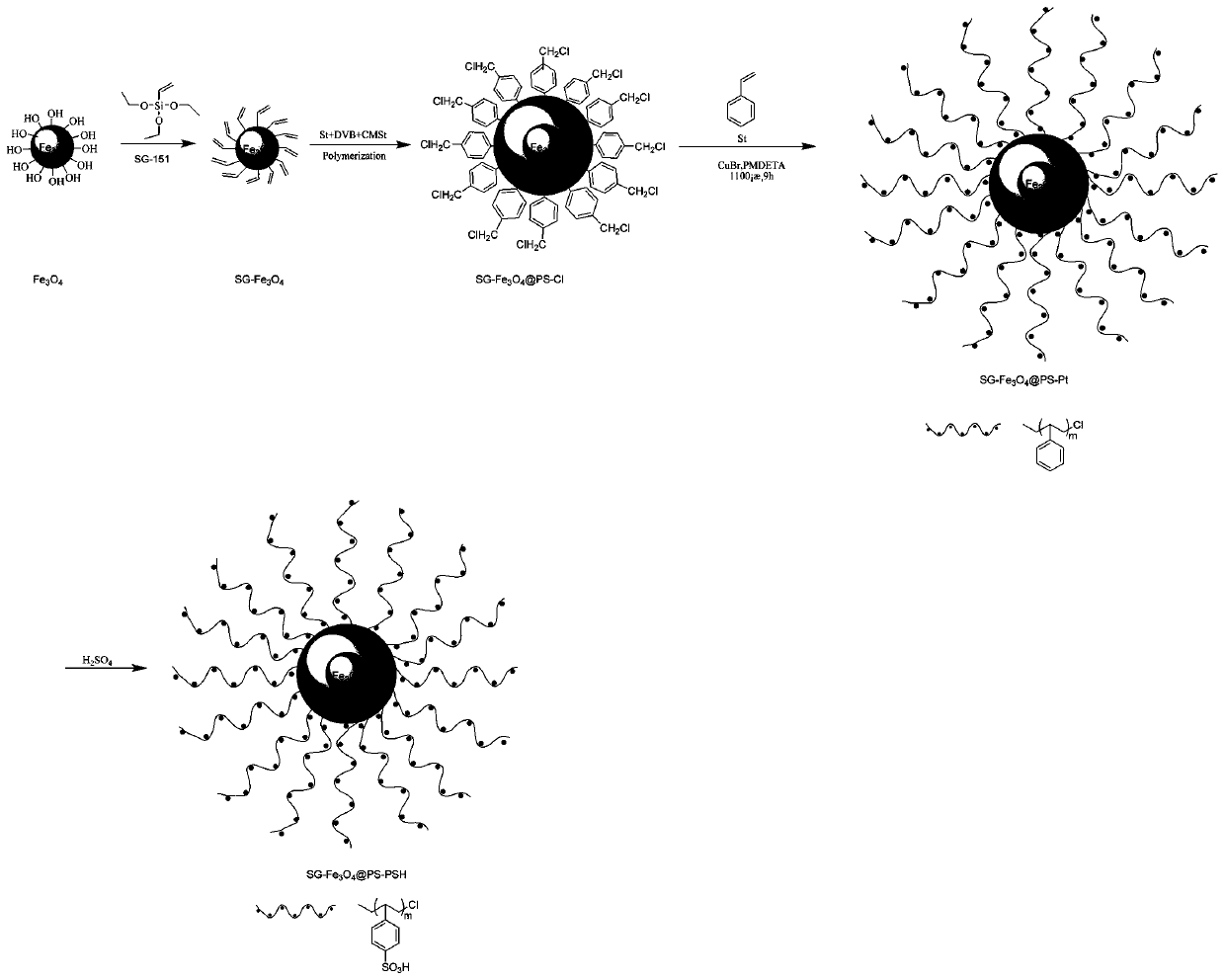

[0031] 1. Preparation of Magnetic Sulfonated Polystyrene Molecular Brush SG-Fe 3 o 4 @PS-PSH

[0032] (1) Accurately weigh 20nm ferric oxide Fe 3 o 4 (6.0 g), vinyltriethoxysilane SG-151 (7.5 g) in a 1000 mL four-neck flask, add 240 mL of absolute ethanol and 20 mL of deionized water, and ultrasonically disperse for 30 min to disperse homogeneous, and stirred at 600 r / min for 16 h in a constant temperature water bath at 40 °C under the protection of nitrogen. After repeated washing with absolute ethanol and deionized water, and vacuum drying at 60 °C for 48 h, SG-Fe 3 o 4 .

[0033] (2) SG-Fe 3 o 4 (6 g), St (11.4168 g, 109.62 mmol), AIBN (0.6 g, 3.654 mmol), DVB (9.5448 g, 73.08 mmol), solvent acetonitrile (600 mL) were placed in a 1000 mL In a four-neck flask, under the protection of nitrogen, stir and reflux for 6 h in a constant temperature oil bath at 80 °C at a speed of 600 r / min. After repeated washing with absolute ethanol and deionized water, dry in a vacuum ...

Embodiment 2

[0041] 1. Preparation of Magnetic Sulfonated Polystyrene Molecular Brush SG-Fe 3 o 4 @PS-PSH

[0042] (1) Accurately weigh 20 nm ferric oxide Fe 3 o 4 (6.0 g), vinyltriethoxysilane SG-151 (7.5 g) in a 1000 mL four-neck flask, add 300 mL of absolute ethanol and 20 mL of deionized water, and ultrasonically disperse for 30 min to disperse homogeneous, and stirred at 600 r / min for 16 h in a constant temperature water bath at 40 °C under the protection of nitrogen. After repeated washing with absolute ethanol and deionized water, and vacuum drying at 60 °C for 48 h, SG-Fe 3 o 4 .

[0043] (2) SG-Fe 3 o 4 (6 g), St (11.4168 g, 109.62 mmol), AIBN (0.6 g, 3.654 mmol), DVB (9.5448 g, 73.08 mmol), solvent acetonitrile (600 mL) were placed in a 1000 mL In a four-neck flask, under the protection of nitrogen, stir and reflux for 6 h in a constant temperature oil bath at 80 °C at a speed of 600 r / min. After repeated washing with absolute ethanol and deionized water, dry in a vacu...

Embodiment 3

[0051] 1. Preparation of Magnetic Sulfonated Polystyrene Molecular Brush SG-Fe 3 o 4 @PS-PSH

[0052] (1) Accurately weigh 20 nm ferric oxide Fe 3 o 4Magnetic powder (6.0 g) and vinyltriethoxysilane SG-151 (7.5 g) were put into a 1000 mL four-neck flask, and 300 mL of absolute ethanol and 20 mL of deionized water were added, and ultrasonically dispersed for 30 min to make it Disperse evenly, and stir at 600 r / min for 16 h in a constant temperature water bath at 40 °C under nitrogen protection. After repeated washing with absolute ethanol and deionized water, and vacuum drying at 60 °C for 48 h, SG-Fe 3 o 4 .

[0053] (2) SG-Fe 3 o 4 (6 g), St (11.4168 g, 109.62 mmol), AIBN (0.6 g, 3.654 mmol), DVB (14.3172 g, 109.62 mmol), solvent acetonitrile (600 mL) were placed in a 1000 mL In a four-neck flask, under the protection of nitrogen, stir and reflux for 6 h in a constant temperature oil bath at 80 °C at a speed of 600 r / min. After repeated washing with absolute ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com