Foamed asphalt containing sodium hypochlorite oxidized waste tire rubber powder

A technology of sodium hypochlorite and waste tire rubber, applied in the field of foamed asphalt, can solve the problems of restricting the wide use of natural asphalt, expensive natural asphalt, limited sources, etc., and achieves improvement of structural strength and compressive performance, preparation speed, and mechanical properties. great effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

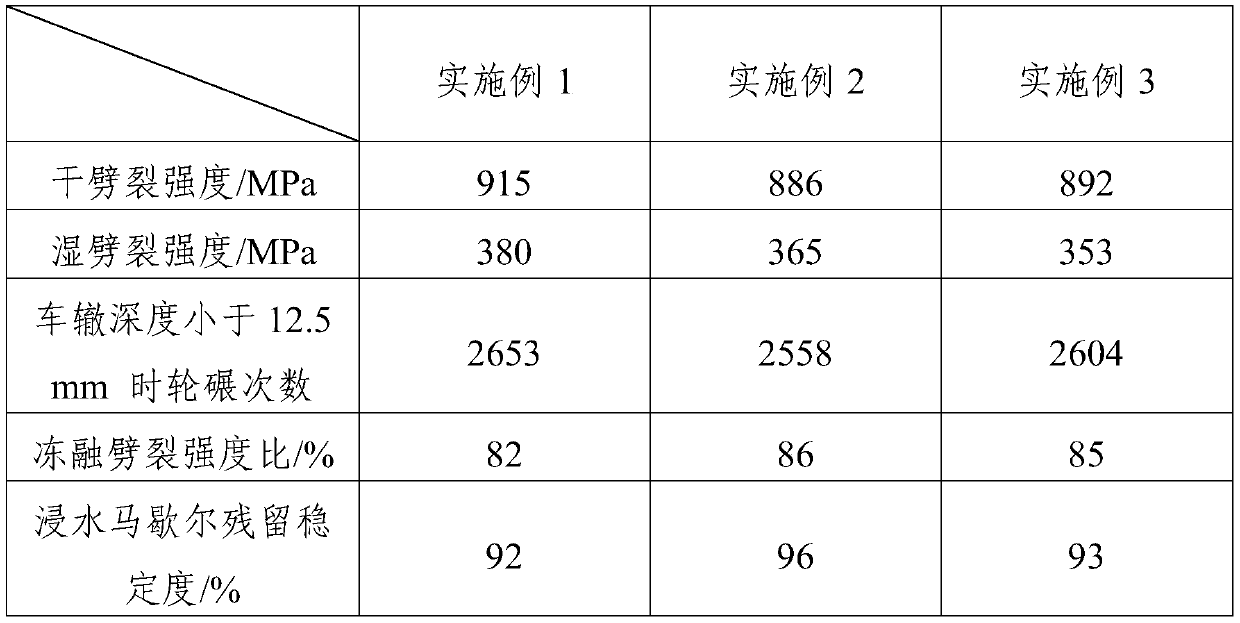

Embodiment 1

[0032] A foamed asphalt containing sodium hypochlorite oxidized waste tire rubber powder is prepared from the following raw materials in parts by weight:

[0033] 43 parts of SBS modified asphalt, 14 parts of zeolite powder / ZnO compound, 25 parts of ordinary Portland cement, 18 parts of sodium hypochlorite oxidized waste tire rubber powder, 20 parts of fly ash, 5 parts of sulfite lactone foaming agent, 0.2 parts of glycidyl methacrylate, 10 parts of dimethyl phthalate, 1 part of hypromellose, 25 parts of basalt rock, 60 parts of aggregate, 2 parts of pentaerythritol, 5 parts of basalt fiber, sodium humate type 15 parts of binder.

[0034] The preparation method of zeolite powder / ZnO composite is as follows:

[0035] Grind the zeolite ball into powder and add it to distilled water, then add zinc nitrate, stir and mix for 10 minutes to obtain reaction solution A, add sodium carbonate and sodium dodecylbenzenesulfonate to distilled water, stir and mix evenly to obtain reaction s...

Embodiment 2

[0043] A foamed asphalt containing sodium hypochlorite oxidized waste tire rubber powder is prepared from the following raw materials in parts by weight:

[0044] 60 parts of SBS modified asphalt, 15 parts of zeolite powder / ZnO compound, 25 parts of ordinary Portland cement, 12 parts of sodium hypochlorite oxidized waste tire rubber powder, 10 parts of fly ash, 1 part of sulfite lactone foaming agent, 0.1 part of glycidyl methacrylate, 7 parts of dimethyl phthalate, 3 parts of hypromellose, 20 parts of basalt rock, 50 parts of aggregate, 2 parts of pentaerythritol, 6 parts of carbon fiber, sodium humate type adhesive 15 parts of binder.

[0045] The preparation method of zeolite powder / ZnO composite is as follows:

[0046] Ground zeolite into powder and added to distilled water, then added zinc nitrate, stirred and mixed for 5 minutes to obtain reaction solution A, added sodium carbonate and sodium dodecylbenzenesulfonate to distilled water, stirred and mixed evenly to obtain...

Embodiment 3

[0054] A foamed asphalt containing sodium hypochlorite oxidized waste tire rubber powder is prepared from the following raw materials in parts by weight:

[0055] 60 parts of SBS modified asphalt, 15 parts of zeolite powder / ZnO compound, 25 parts of ordinary Portland cement, 14 parts of sodium hypochlorite oxidized waste tire rubber powder, 12 parts of fly ash, 1 part of sulfite lactone foaming agent, 0.2 parts of glycidyl methacrylate, 6 parts of dimethyl phthalate, 3 parts of hypromellose, 25 parts of basalt rock, 60 parts of aggregate, 3 parts of pentaerythritol, 5 parts of quartz glass fiber, sodium humate Type binder 12 parts.

[0056] The preparation method of zeolite powder / ZnO composite is as follows:

[0057] Grind the zeolite ball into powder and add it to distilled water, then add zinc nitrate, stir and mix for 10 minutes to obtain reaction solution A, add sodium carbonate and sodium dodecylbenzenesulfonate to distilled water, stir and mix evenly to obtain reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com