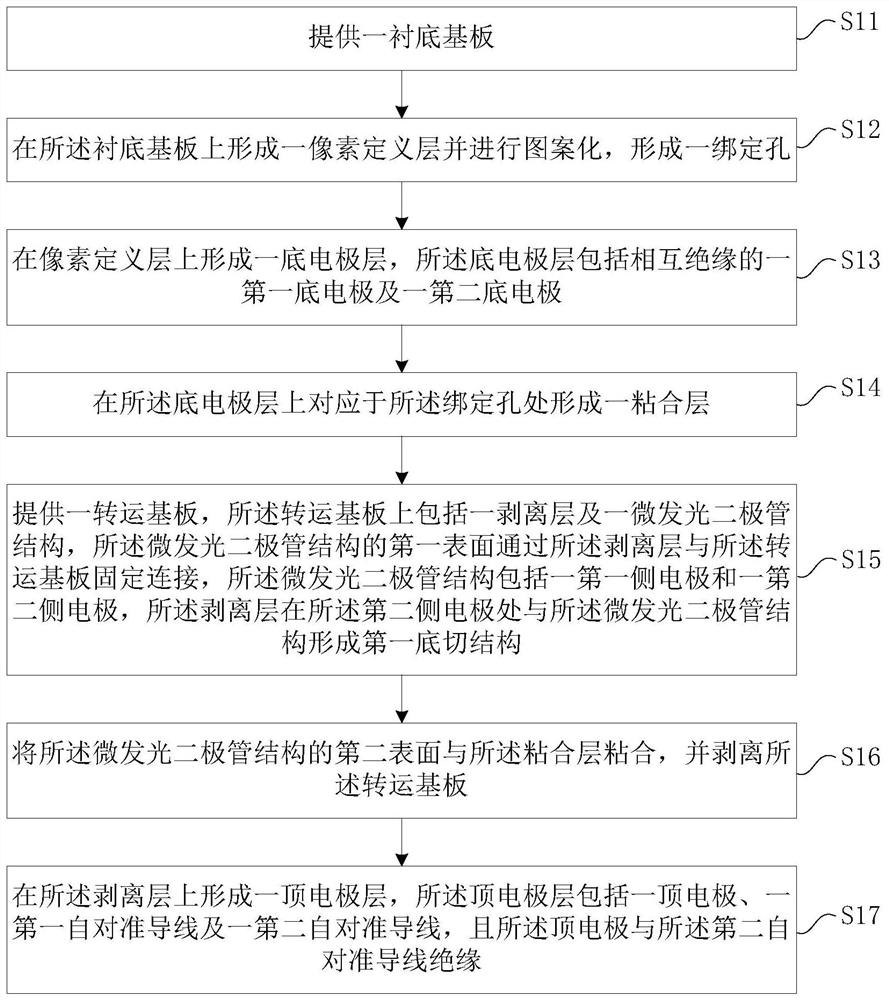

A micro light emitting diode display substrate and its preparation method

A technology for micro-light-emitting diodes and display substrates, which is used in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve problems such as increased repair costs, complicated bonding processes, and poor binding, and saves money. Production cost, improved device fabrication yield, and effects of good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

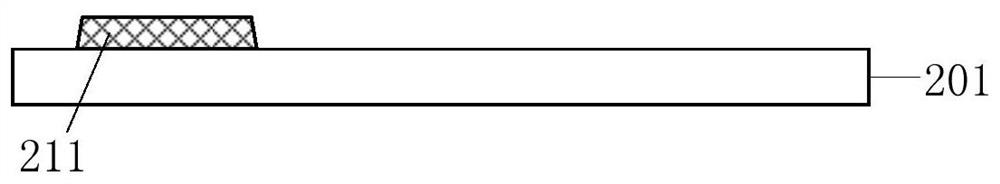

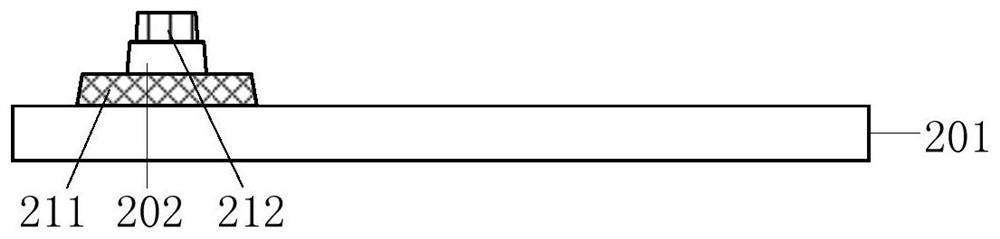

[0014] Embodiments of the present application are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals denote the same or similar components or components having the same or similar functions throughout. The terms "first", "second", "third", etc. (if any) in the description and claims of this application and the drawings are used to distinguish similar objects and not necessarily to describe a specific order or sequence . It should be understood that the items so described are interchangeable under appropriate circumstances. Furthermore, the terms "comprising" and "having", as well as any variations thereof, are intended to cover a non-exclusive inclusion. The directional terms mentioned in this application, such as: up, down, left, right, front, back, inside, outside, side, etc., are only directions referring to the drawings.

[0015] The embodiments described below with reference to the drawings and the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com