Coal mine gas prediction method based on deep learning

A coal mine gas and deep learning technology, applied in neural learning methods, prediction, biological neural network models, etc., can solve problems without further mining and discovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

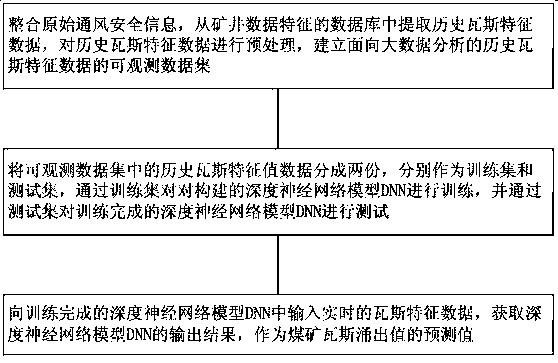

[0036] refer to figure 1 , providing a coal mine gas prediction method based on deep learning, including steps:

[0037] Integrate the original ventilation safety information, extract historical gas characteristic data from the database of mine data characteristics, preprocess the historical gas characteristic data, and establish an observable data set of historical gas characteristic data for big data analysis;

[0038] The historical gas eigenvalue data in the observable data set is divided into two parts, which are used as the training set and the test set respectively. The trained deep neural network model DNN is trained through the training set, and the trained deep neural network model is trained through the test set. DNN for testing;

[0039] Input the real-time gas characteristic data into the trained deep neural network model DNN, and obtain the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com