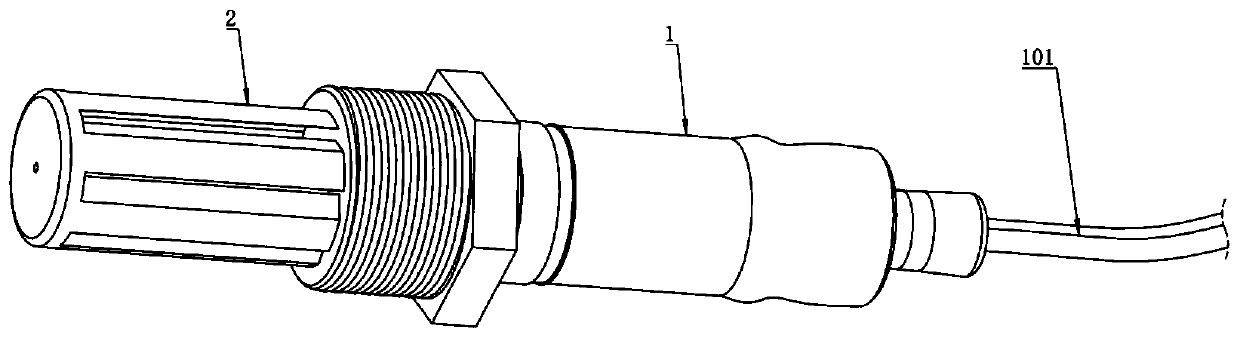

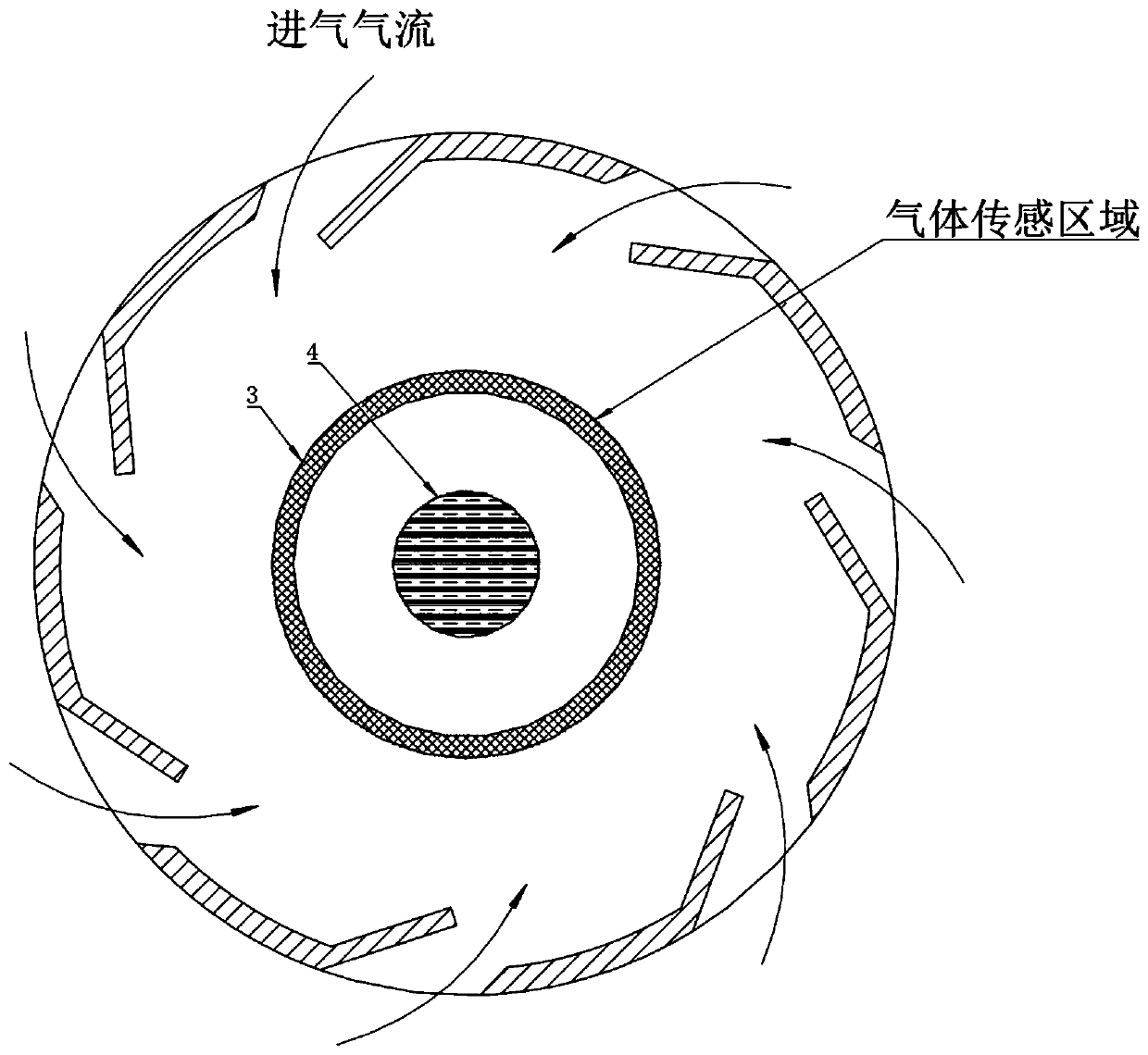

Vehicle oxygen sensor with quick response and strong anti-interference capability

A vehicle-used oxygen sensor and fast-response technology, applied in the field of oxygen sensors, can solve the problems of intermittent exhaust airflow, unstable airflow, and poor timeliness of signal feedback, and achieve the effects of increasing response speed, uniform heating, and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

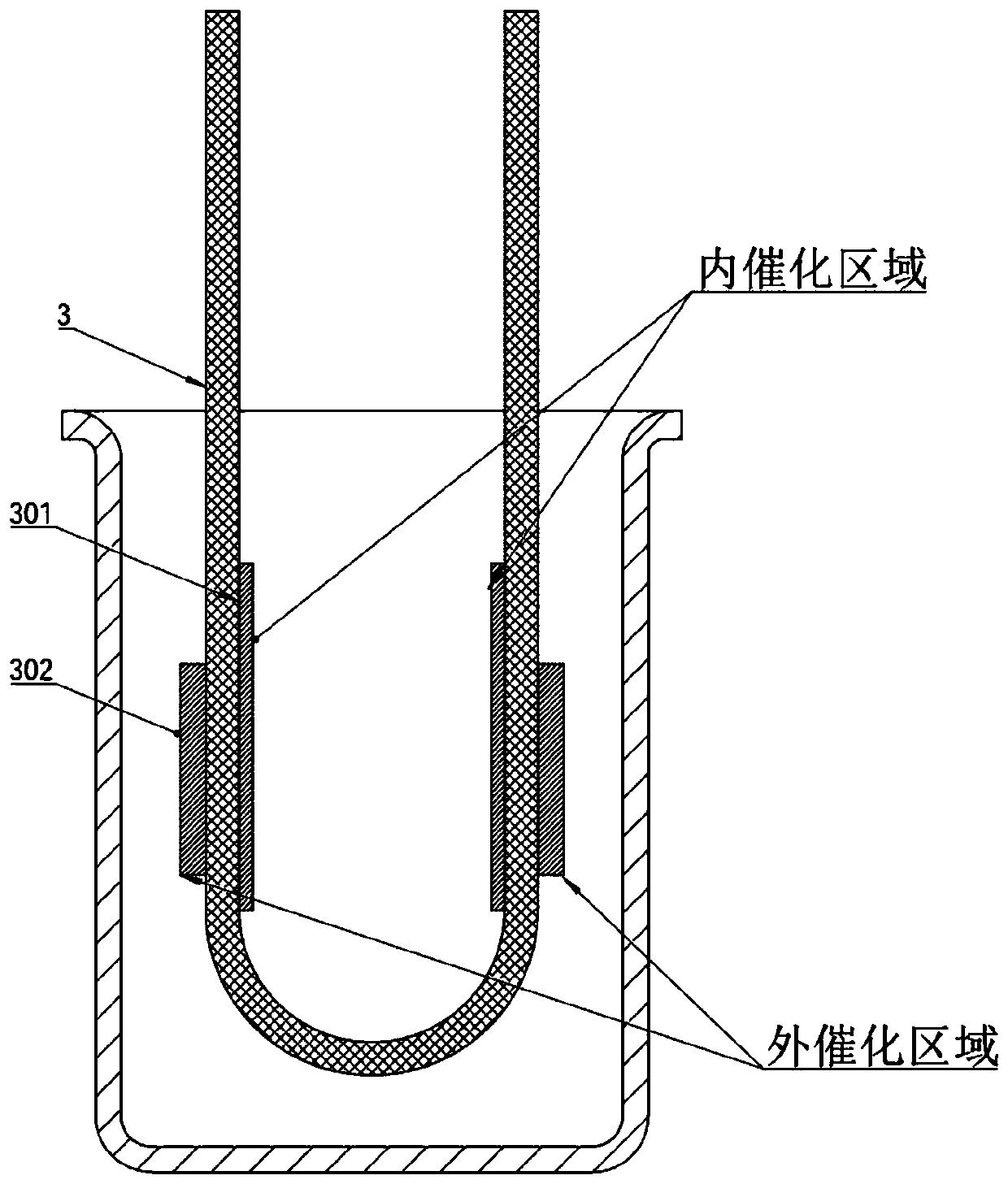

[0040] The preparation method of zirconium tube catalytic layer comprises the following steps:

[0041] a. Add fusion additives to the electrode platinum slurry;

[0042] b. Ball milling into a uniform slurry, which is sprayed inside and outside the zirconium tube by a spraying machine, and the coating area ratio of the inner and outer catalytic layers is 0.8; it is made into a green body;

[0043] c. Carry out four-stage sintering to the green body;

[0044] d. The first stage is the preheating stage, the temperature is 100°C, and the duration is 2 hours; it is used to remove the moisture in the green body; the temperature is raised slowly (the purpose is to slowly volatilize the residual moisture in the green body, and countless tiny particles are formed during the volatilization process. Pores, forming a microscopic porous surface) relatively long time of heat preservation is conducive to the complete evaporation of water, on the one hand, more micropores are formed, on th...

Embodiment 2

[0051] The preparation method of zirconium tube catalytic layer comprises the following steps:

[0052] a. Add fusion additives to the electrode platinum slurry;

[0053] b. Ball milling into a uniform slurry, which is sprayed inside and outside the zirconium tube by a spraying machine, and the coating area ratio of the inner and outer catalytic layers is 1; it is made into a green body;

[0054] c. Carry out four-stage sintering to the green body;

[0055] d. The first stage is the preheating stage, the temperature is 100°C, and the duration is 2 hours; it is used to remove the moisture in the green body; the temperature is raised slowly (the purpose is to slowly volatilize the residual moisture in the green body, and countless tiny particles are formed during the volatilization process. Pores, forming a microscopic porous surface) relatively long time of heat preservation is conducive to the complete evaporation of water, on the one hand, more micropores are formed, on the ot...

Embodiment 3

[0063] The preparation method of zirconium tube catalytic layer comprises the following steps:

[0064] a. Add fusion additives to the electrode platinum slurry;

[0065] b. Ball milling into a uniform slurry, which is sprayed inside and outside the zirconium tube by a spraying machine, and the coating area ratio of the inner and outer catalytic layers is 1.2; it is made into a green body;

[0066] c. Carry out four-stage sintering to the green body;

[0067] d. The first stage is the preheating stage, the temperature is 100°C, and the duration is 2 hours; it is used to remove the moisture in the green body; the temperature is raised slowly (the purpose is to slowly volatilize the residual moisture in the green body, and countless tiny particles are formed during the volatilization process. Pores, forming a microscopic porous surface) relatively long time of heat preservation is conducive to the complete evaporation of water, on the one hand, more micropores are formed, on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com