Manufacturing method of plant tissue semi-thin section

A production method and technology of plant tissue, applied in the biological field, can solve the problems of lack of layers, expensive glass knife, no contrast, etc., achieve the effect of improving quality and image effect, simple and easy configuration process, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0031] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

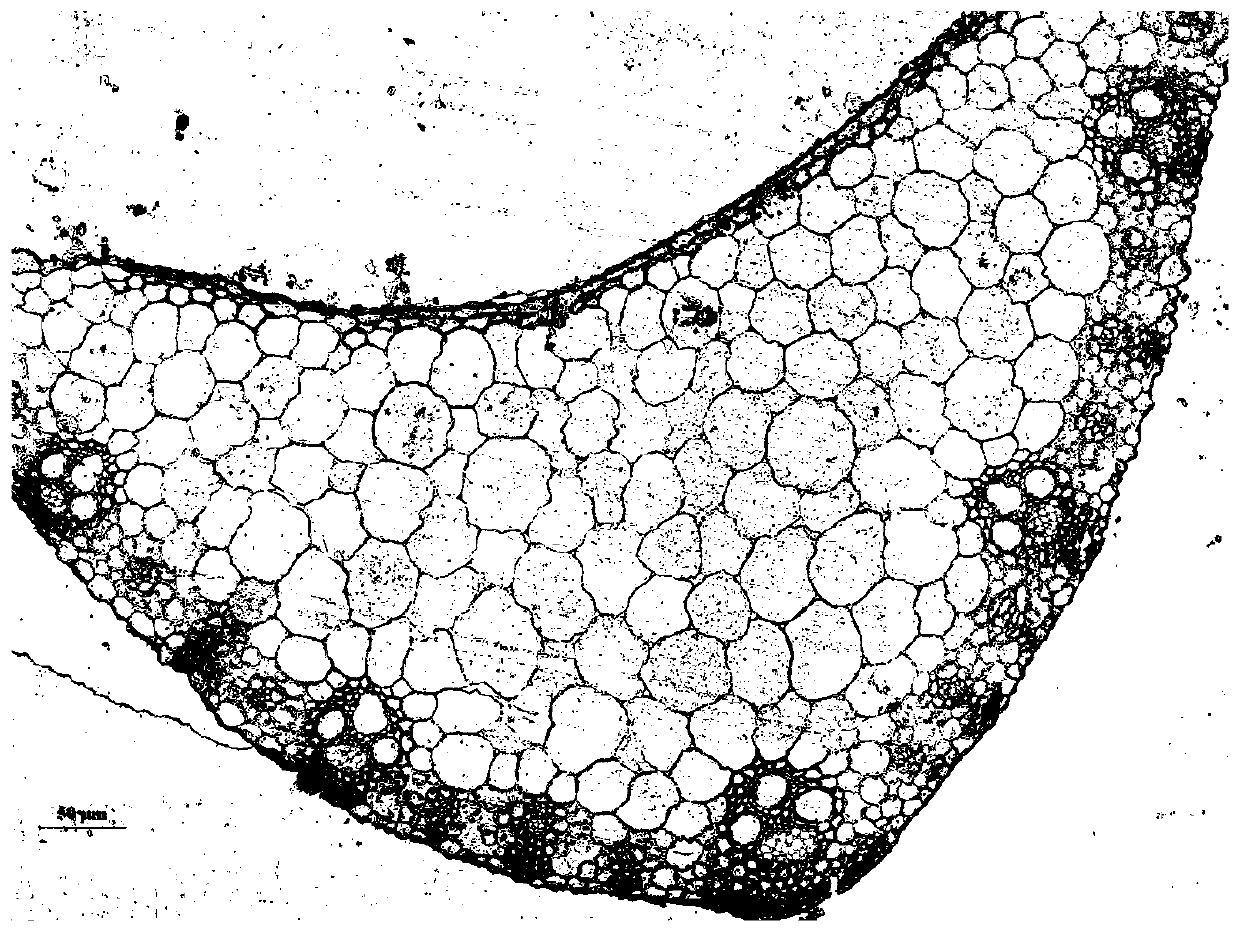

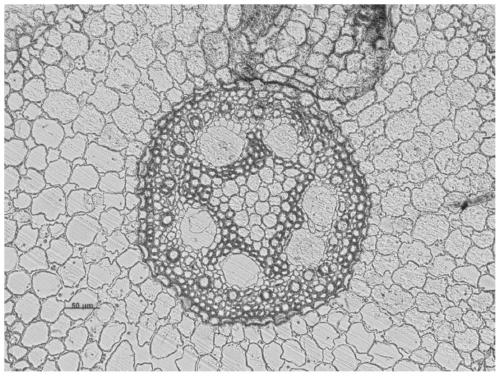

[0032] Such as figure 1 Shown, be the flow chart of the present invention to sorghum leaf safranin fast green counterstain semi-thin section:

[0033] (1) Material collection: the leaves with a size of 0.6cm×0.6cm can be selected in different growth stages except for the vein part;

[0034] (2) Fixing: fix the taken leaves in 2.5% glutaraldehyde fixative solution for more than 24 hours, and vacuumize to fully fix the tissues and cells;

[0035] (3) Rinse: Rinse the fixed leaves with 0.1M PBS buffer solution for 3 times, each time for 20 minutes; then rinse with distilled water for 2 times, each time for 20 minutes, to fully wash off the fixative;

[0036] (4) Dehydration: use 50%, 70%, 80%, 90%, 95%, 100% ethanol to dehydrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com