Reinforced concrete laminated slab adopting zigzag folded plates for connection and preparation method

A technology of reinforced concrete and laminated slabs, which is applied to floors, building components, buildings, etc., can solve the problems of inconvenient construction on site, high project cost, and high cost, so as to achieve less deformation and dislocation, enhance shear bearing capacity, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

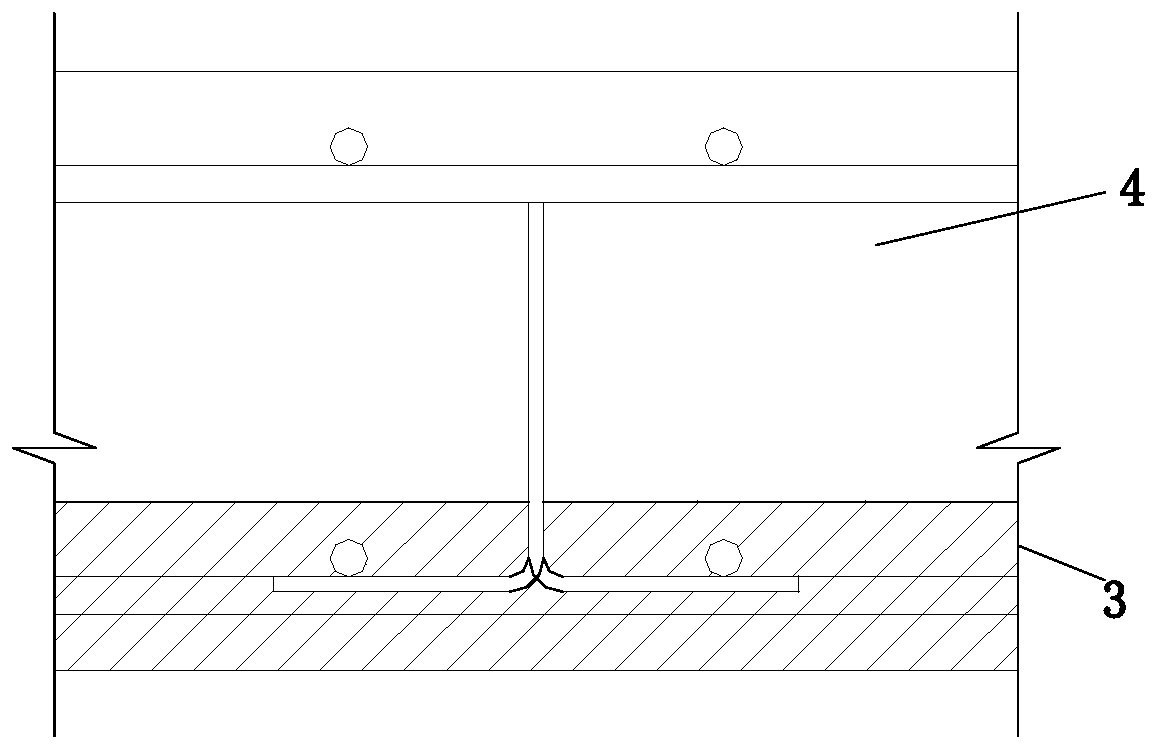

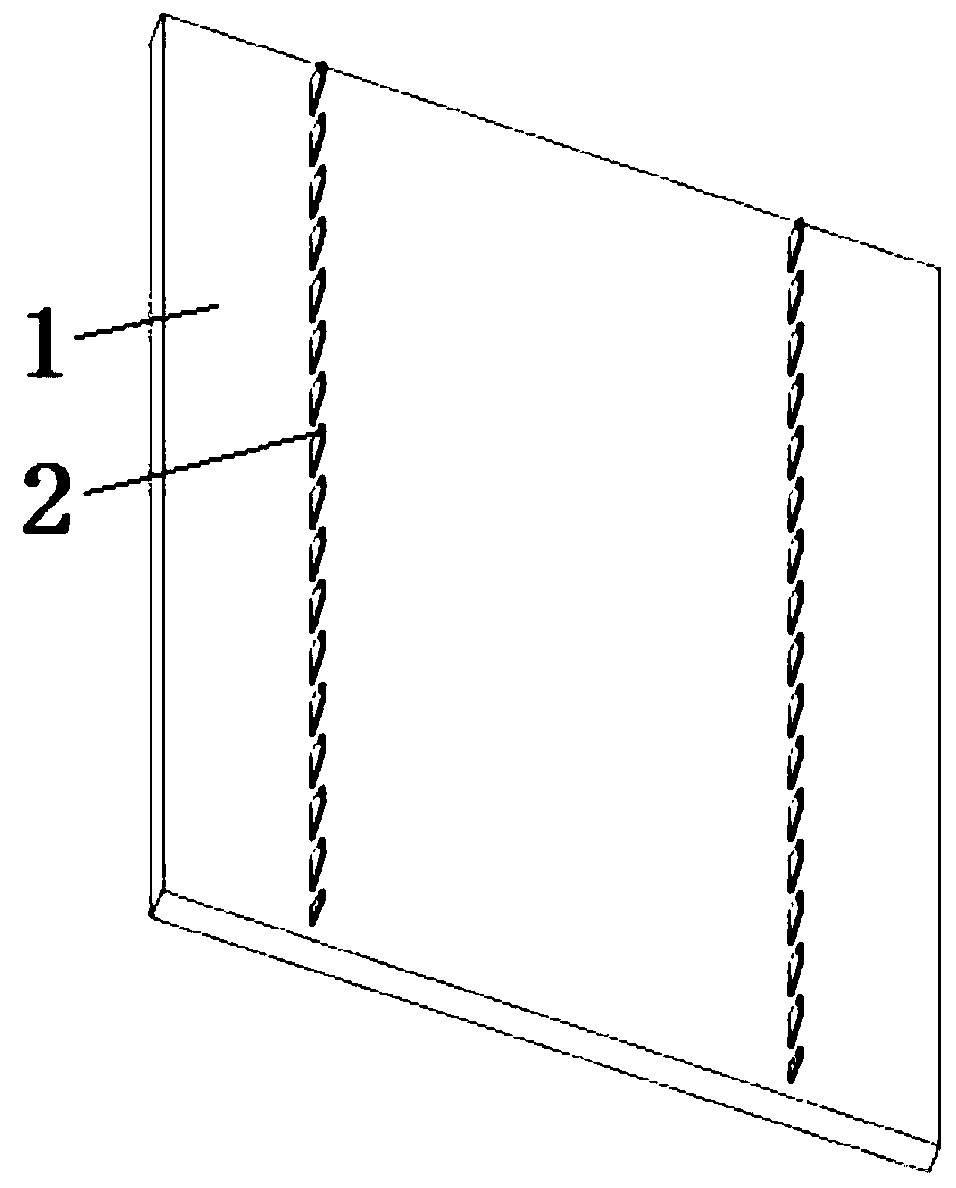

[0037] Example 1. A reinforced concrete laminated slab connected by folded slabs, constituted as Figure 1 to Figure 10 As shown, it includes a laminated slab bottom plate 3, and a concrete cast-in-place layer 4 is arranged above the laminated slab bottom plate 3; the laminated slab bottom plate 3 includes a prefabricated bottom plate 1, and a molded folding plate 2 is provided in the prefabricated bottom plate 1; The upper part of the slab 2 is located above the prefabricated floor 1 .

[0038] The prefabricated floor 1 includes a prefabricated concrete layer 101. The precast concrete layer 101 is provided with a prefabricated floor internal reinforcement layer 102, and the bottom of the folded plate 2 is connected to the prefabricated floor internal reinforcement layer 102 by welding.

[0039] Described type folding plate 2 comprises vertical plate 201, is provided with a group of vertical connecting plate 202 that cross-section is trapezoidal structure above vertical plate...

Embodiment 2

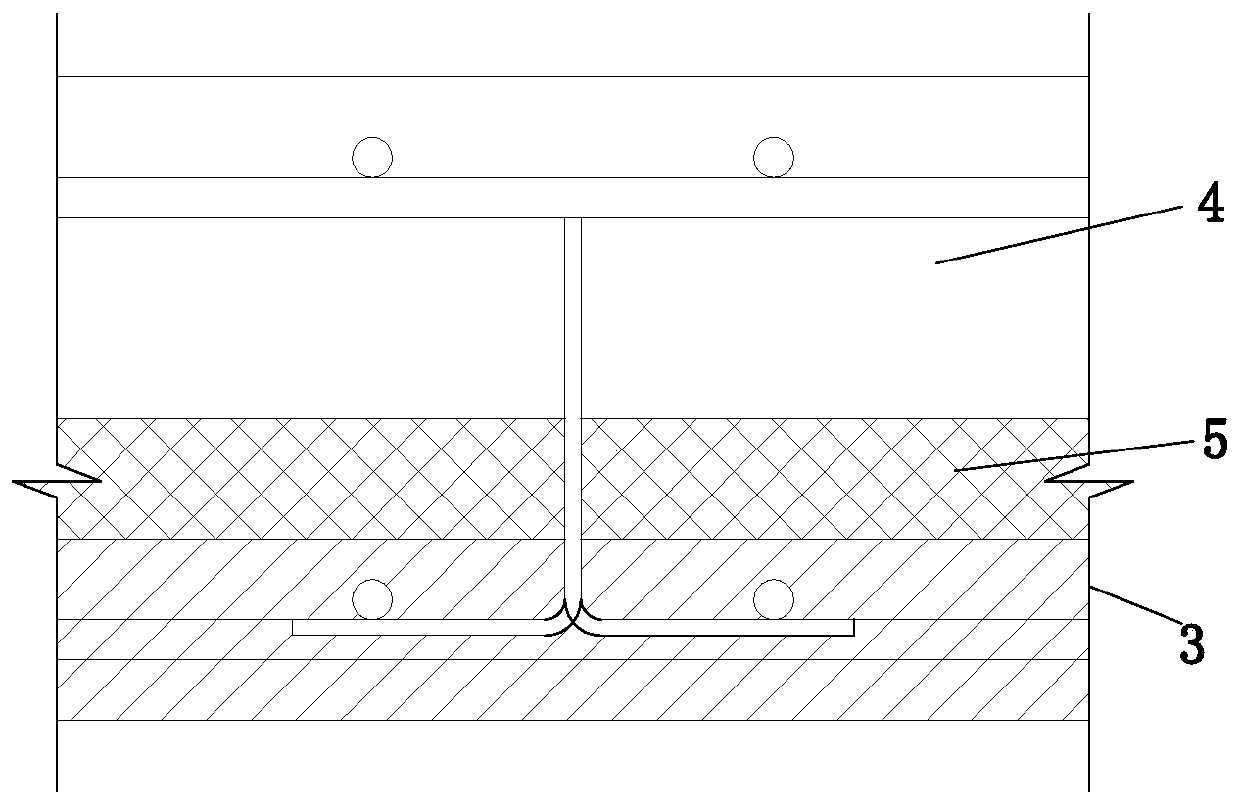

[0056] Example 2. A reinforced concrete laminated slab connected by folded slabs, constituted as Figure 1 to Figure 4 as well as Figure 11 to Figure 13 As shown, it includes a laminated slab bottom plate 3, and a concrete cast-in-place layer 4 is arranged above the laminated slab bottom plate 3; the laminated slab bottom plate 3 includes a prefabricated bottom plate 1, and a molded folding plate 2 is provided in the prefabricated bottom plate 1; The upper part of the slab 2 is located above the prefabricated floor 1 .

[0057] The prefabricated floor 1 includes a prefabricated concrete layer 101. The precast concrete layer 101 is provided with a prefabricated floor internal reinforcement layer 102, and the bottom of the folded plate 2 is connected to the prefabricated floor internal reinforcement layer 102 by welding.

[0058] Described type folding plate 2 comprises vertical plate 201, is provided with a group of vertical connecting plate 202 that cross-section is trapezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com