Road structure of urban intersection, bus station and bus lane

A technology for bus-only lanes and intersections, which is applied in the field of road engineering, can solve the problems of small depth of semi-flexible pavement surface structure, poor crack resistance, and easy falling off of grouting materials, so as to achieve sustainable development, solve water damage, Realize the effect of mass utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

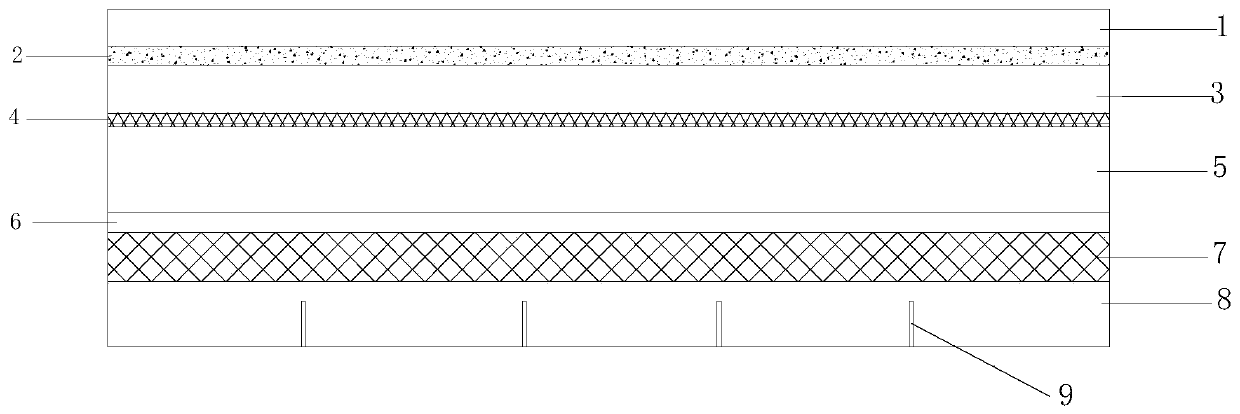

[0031] Example 1, such as figure 1 Shown, according to the road structure of a kind of urban intersection, bus stop and bus lane of the present invention, described road structure comprises surface layer 1, middle surface layer 3, lower layer 5, base layer 7 and subbase layer from top to bottom 8. A rubber asphalt stress-absorbing layer 6 is arranged between the lower layer 4 and the base layer 7, wherein the surface layer 1 is composed of semi-flexible material SFA13 sprayed with dew stone agent in 4cm-6cm; the middle surface layer 3 is composed of 6cm ~8cm is composed of semi-flexible material SFA16 mixed with phase change energy storage materials; the lower layer 5 is composed of 8cm~10cm high-ratio RAP EME20 high modulus asphalt mixture, and the base layer 7 is 18cm~20cm mixed with bagasse fiber , waste rubber powder and water-absorbing resin polyacrylic acid sodium salt C-B-1 cement stabilized graded gravel or gravel, a first adhesive layer 2 is arranged between the surfa...

Embodiment 2

[0070] Example 2, the surface layer 1 is made of a 4cm semi-flexible material SFA13 sprayed with dew stone agent; the middle surface layer 3 is made of a 6cm semi-flexible material SFA16 mixed with a phase change energy storage material; the lower layer 5 is made of a 10cm high The EME20 high modulus asphalt mixture with a ratio of RAP is formed, and the base layer 7 is composed of 18cm C-B-1 cement-stabilized crushed stone or gravel mixed with bagasse fiber, waste rubber powder and water-absorbing resin polyacrylic acid sodium salt. A first adhesive layer 2 is arranged between the surface layer 1 and the middle layer 3, and a second adhesive layer 4 is arranged between the middle layer 3 and the lower layer 5. The first adhesive layer 2 and the second adhesive layer 4 are SBS modified asphalt adhesive layer or modified emulsified asphalt adhesive layer, the spreading amount per unit area is 0.8kg / m 2 , the thickness of the rubber asphalt stress absorbing layer 6 is 0.8cm; the...

Embodiment 3

[0072] Embodiment 3, the surface layer 1 is made of 6cm semi-flexible material SFA13 sprayed with dew stone agent; the middle surface layer 3 is made of 8cm semi-flexible material SFA16 mixed with phase change energy storage material; the lower layer 5 is made of 8cm high The EME20 high modulus asphalt mixture with a ratio of RAP is formed, and the base layer 7 is composed of C-B-1 cement-stabilized graded crushed stone or gravel mixed with bagasse fiber, waste rubber powder and water-absorbing resin polyacrylic acid sodium salt of 20 cm. A first adhesive layer 2 is arranged between the surface layer 1 and the middle layer 3, and a second adhesive layer 4 is arranged between the middle layer 3 and the lower layer 5. The first adhesive layer 2 and the second adhesive layer 4 are SBS modified asphalt adhesive layer or modified emulsified asphalt adhesive layer, the spreading amount per unit area is 0.7kg / m 2 , the thickness of the rubber asphalt stress absorbing layer 6 is 1.3cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com