F-containing sintered ore and production method thereof

A production method and technology for sintered ore, which are applied in the field of F-containing sintered ore and its production, can solve the problems of low drum strength and affect the forward running of a blast furnace, and achieve the effects of ensuring long-term forward running and improving microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

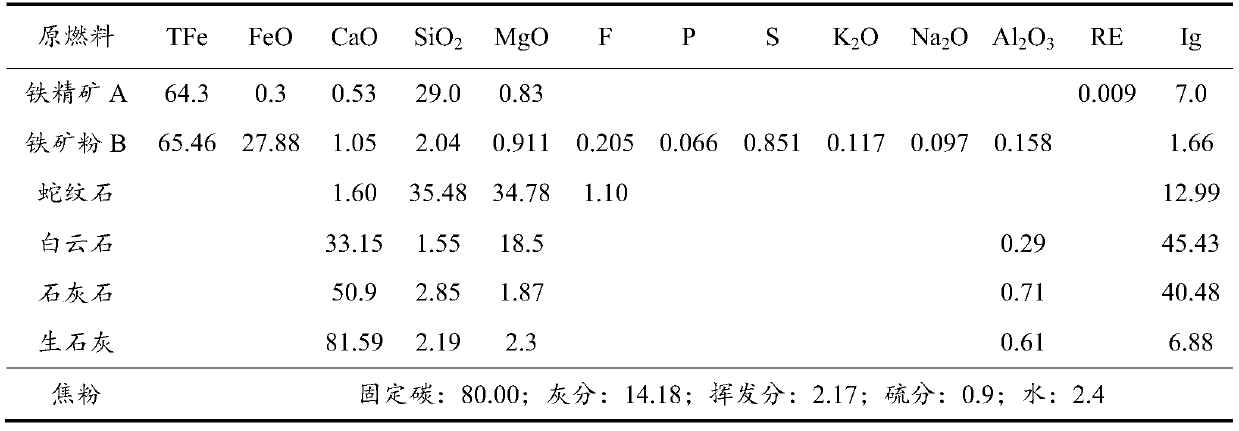

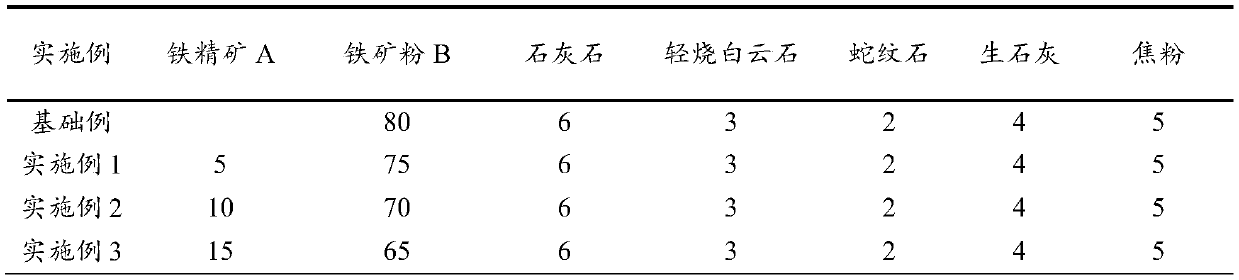

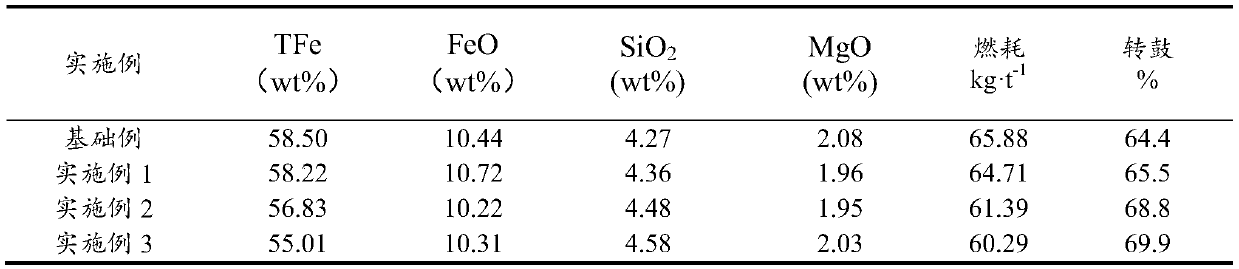

[0024] 1) According to the raw material and fuel shown in Table 1 below and the proportion shown in Table 2 below, the iron ore powder B has a particle size of 95% through a 200-mesh screen to obtain the raw material;

[0025] 2) The raw materials are mixed with water in a primary mixer, and the moisture content is controlled to 7.0%; then granulated in a secondary mixer with a granulating time of 5 minutes to obtain pellets. The average particle size of the pellets is 10mm;

[0026] 3) After granulation, the pellets are evenly distributed to the sintering device through the distributor. The thickness of the material layer is 700mm. The ignition is carried out by the sintering igniter. The ignition fuel is natural gas. The ignition time is 2.0min. At the same time, the bottom of the sintering device starts to draw air. A certain negative pressure is formed under the grate, the ignition negative pressure is 6000Pa, after ignition, the air is drawn from the top to the bottom through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com