Process method for extracting three enzymes from animal pancreas

A process method, pancreas technology, applied in the field of bioengineering, can solve the problems of high price, low product purity, and other enzyme structure damage, and achieve the effects of reducing resource waste, high product purity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

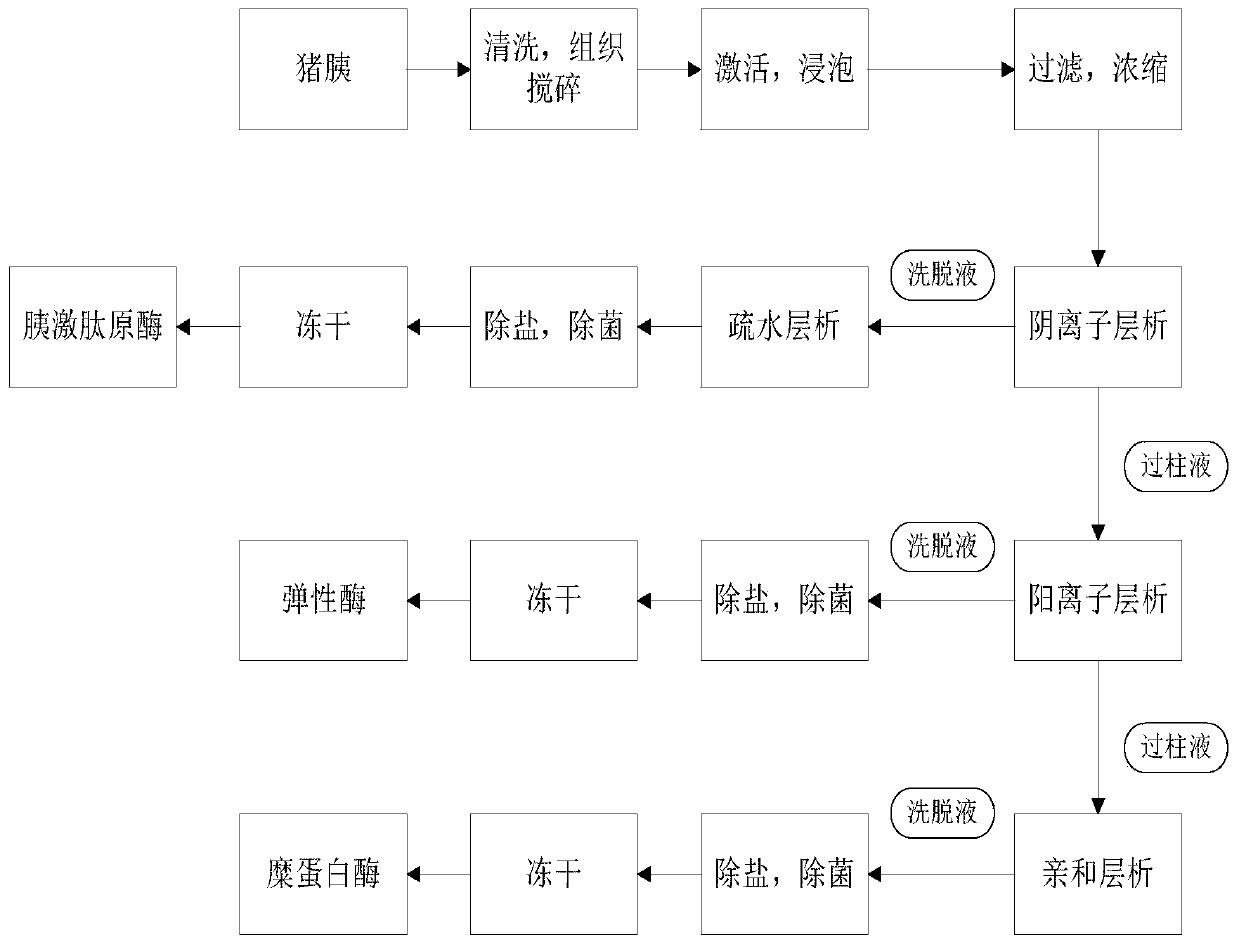

[0044] Such as figure 1 As shown, the invention provides a process for extracting three enzymes from animal pancreas.

[0045] The concrete implementation process of this method is as follows:

[0046] Step 101: Mincing the tissue: Mincing the pancreas of the animal to obtain a tissue pulp.

[0047] Wherein, in combination with specific implementation scenarios, the animal pancreas can be fresh porcine pancreas or bovine pancreas, and the fat and connective tissue are removed, washed and minced with a meat grinder.

[0048] Step 102: Activation and soaking: adding calcium chloride solution to the tissue pulp, adjusting the pH to the first pH range, and incubating at 35°C-45°C.

[0049]Wherein, in combination with specific implementation scenarios, the calcium chloride solution can be 1-5% calcium chloride solution, and calcium ions in calcium chloride can activate pancreatic kininogenase during soaking, and calcium ions can act on chymotrypsin Protective effect, inhibiting ...

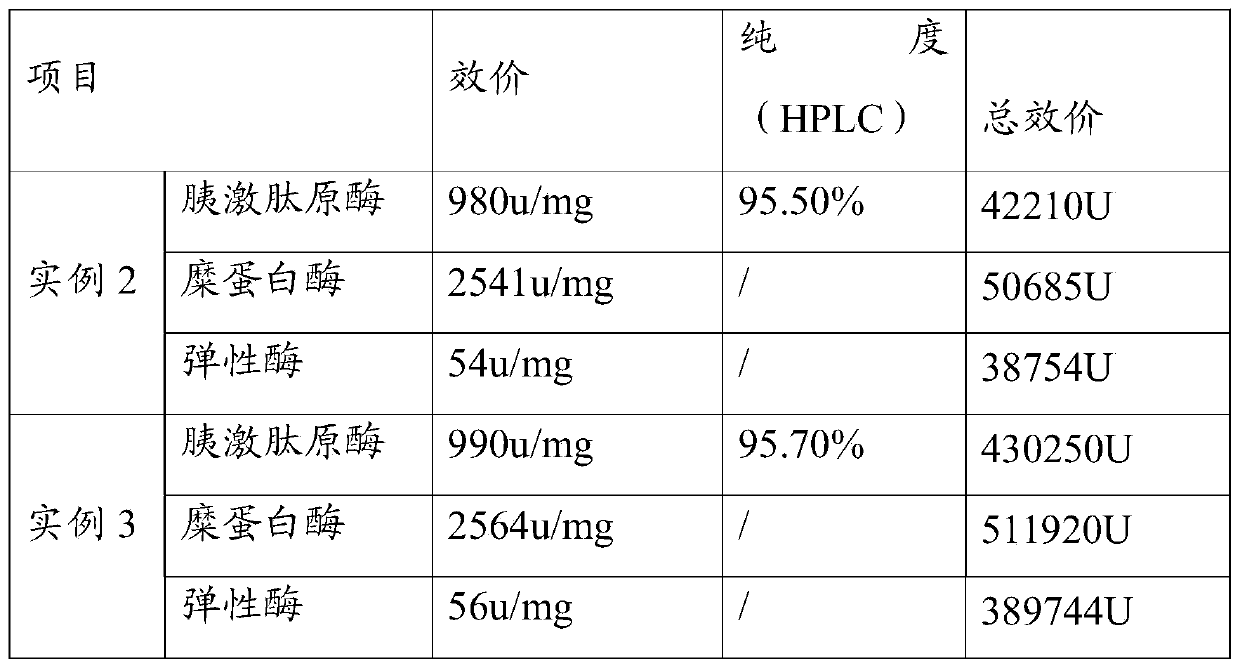

Embodiment 2

[0062] Step 201: Grinding the tissue: take 1000 grams of fresh frozen pig, remove the fat and connective tissue, wash it with water, and grind it with a meat grinder.

[0063] Step 202: Activation and soaking: Add 5 liters of 3% calcium chloride solution, adjust the pH to 7.0, stir, and put it in a 40°C water bath for 4 hours.

[0064] Step 203: Filtration and Concentration: After the heat preservation is completed, add 5% diatomaceous earth for filtration, and the obtained filtrate 1 is ultrafiltered with a 10KD ultrafiltration membrane to obtain a 300 mL solution.

[0065] Step 204: Q Sepharose FF anion exchange chromatography: After the ion exchange chromatography column is equilibrated with a balance solution (0.1M HAc-NaAc, pH 5), adjust the pH of the concentrated solution after the ultrafiltration to 5, and put it on at a flow rate of 5ml / min Column, collect the column liquid 1, elute with the eluent (0.1M HAc-NaAc+0.5M NaCl, pH5), and collect the eluate 1.

[0066] Ste...

Embodiment 3

[0070] Step 301: Grinding the tissue: take 10 kg of fresh frozen pigs, remove the fat and connective tissue, wash them with clean water, and grind them with a meat grinder.

[0071] Step 302: Activation and soaking: Add 50 liters of 3% calcium chloride solution, adjust the pH to 7.0, stir, and put it in a 40°C water bath for 4 hours.

[0072] Step 303: Filtration and Concentration: After the heat preservation is completed, add 5% diatomaceous earth for filtration, and the obtained filtrate 1 is ultrafiltered with a 10KD ultrafiltration membrane to obtain 1000 ml of a solution.

[0073] Step 304: Q Sepharose FF anion exchange chromatography: After the ion exchange chromatography column is equilibrated with an equilibrium solution (0.1M HAc-NaAc, pH 5), adjust the pH of the concentrated solution after ultrafiltration to 5, and put it on at a flow rate of 5ml / min Column, collect the column liquid 1, elute with the eluent (0.1M HAc-NaAc+0.5M NaCl, pH5), and collect the eluate 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com