Graphene supported spherical copper/cuprous oxide/cupric oxide composite material and its preparation method and application

A cuprous oxide and composite material technology, applied in the petroleum industry, lubricating compositions, additives, etc., to achieve the effect of simple preparation method, excellent anti-wear and anti-friction properties, and inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

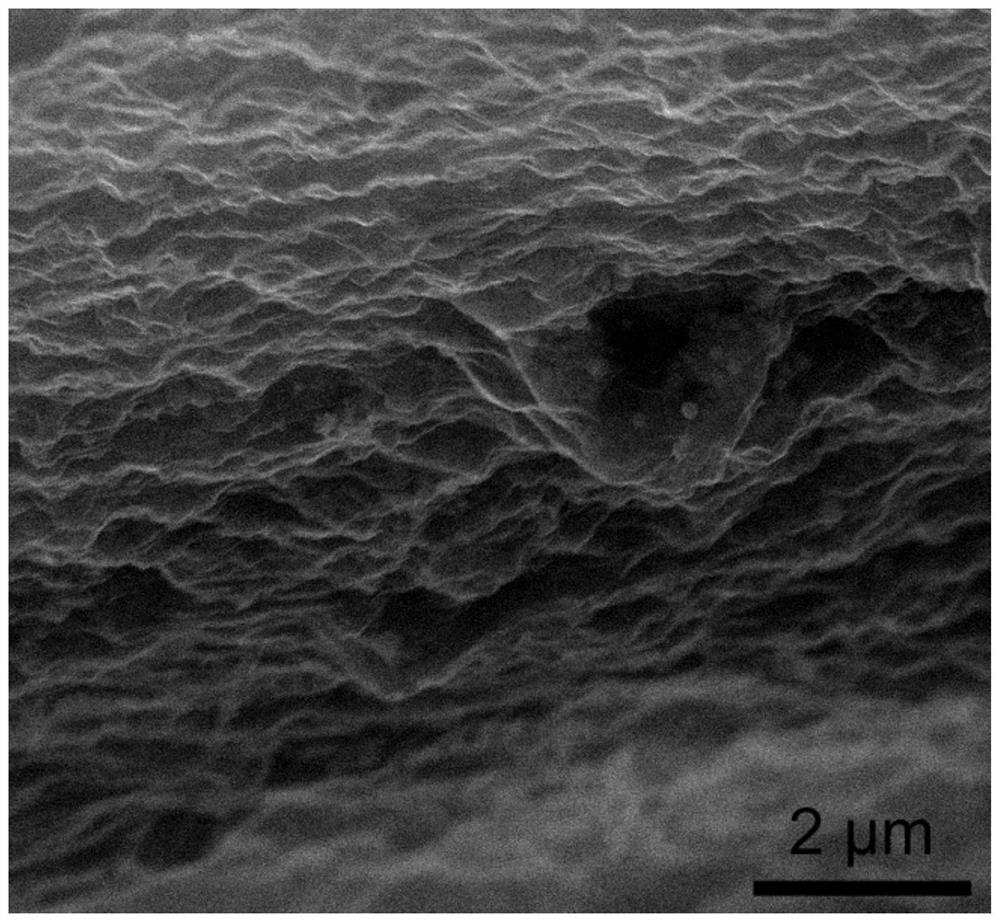

Image

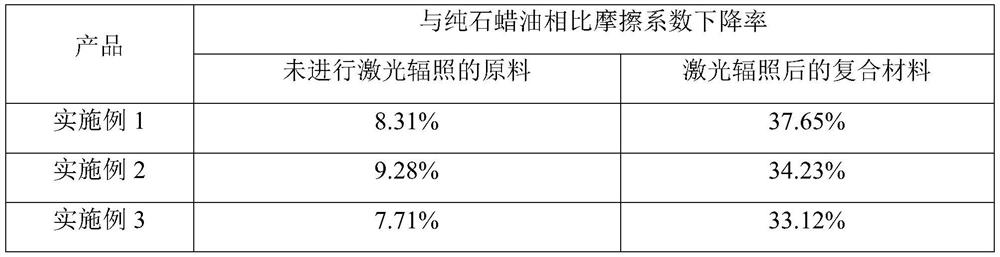

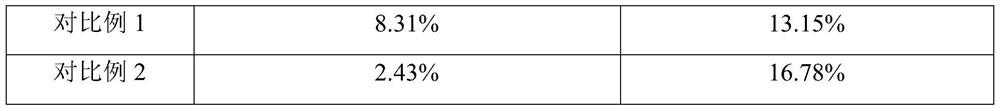

Examples

Embodiment 1

[0044] (1) Weigh 500 mg of copper oxide powder into a beaker, add 100 mL of deionized water, and disperse ultrasonically until there is no precipitation at the bottom of the beaker to form a uniform suspension.

[0045] (2) Add the graphene oxide solution to the suspension in step (1), and disperse it ultrasonically for 20 minutes to obtain a mixed suspension, in which the mass ratio of copper oxide to graphene oxide is 0.9:0.1.

[0046] (3) The above-mentioned mixed suspension is irradiated with the pulsed laser beam focused by the mirror and the convex lens, and the mixed suspension is pulsed laser irradiated under stirring, and the stirring speed is 500r min -1 ; The condition of pulsed laser beam irradiation is: pulsed laser energy density is 600mJ pulse -1 cm -2 , the frequency is 10Hz, and the irradiation time is 30min; the graphene oxide and copper oxide are transformed into copper / cuprous oxide / cupric oxide supported on reduced graphene oxide under the photothermal ac...

Embodiment 2

[0049] (1) Weigh 10mg of copper oxide powder into a beaker, add 100mL of deionized water, and ultrasonically disperse until there is no precipitation at the bottom of the beaker to form a uniform suspension.

[0050] (2) Adding the graphene oxide solution into the suspension in step (1), and ultrasonically dispersing for 5 minutes to obtain a mixed suspension, the mass ratio of copper oxide and graphene oxide in the mixed suspension is 0.85:0.15.

[0051] (3) The above-mentioned mixed suspension is irradiated with the focused pulsed laser beam, and the mixed suspension is pulsed laser irradiated under stirring, and the stirring speed is 300r min -1 ; The condition of pulsed laser beam irradiation is: pulsed laser energy density is 300mJpulse -1 cm -2 , the frequency is 1Hz, and the irradiation time is 60min; the graphene oxide and copper oxide are converted into copper / cuprous oxide / cupric oxide supported on reduced graphene oxide under the photothermal action and reduction a...

Embodiment 3

[0053] (1) Weigh 1000mg of copper oxide powder into a beaker, add 100mL of deionized water, and ultrasonically disperse until there is no precipitation at the bottom of the beaker to form a uniform suspension.

[0054] (2) Adding the graphene oxide solution into the suspension in step (1), and ultrasonically dispersing for 30 minutes to obtain a mixed suspension, the mass ratio of copper oxide to graphene oxide in the mixed suspension is 0.95:0.05.

[0055] (3) The above-mentioned mixed suspension is irradiated with the focused pulsed laser beam, and the mixed suspension is pulsed laser irradiated under stirring, and the stirring speed is 2000r min -1 ; The condition of pulsed laser beam irradiation is: pulsed laser energy density is 1000mJ pulse -1 cm -2 , the frequency is 15Hz, and the irradiation time is 5min; the graphene oxide and copper oxide are converted into copper / cuprous oxide / cupric oxide supported on reduced graphene oxide under the photothermal effect and reduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com