High-viscosity polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof and high-viscosity technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of coating heat dissipation decline, affecting equipment use, coating aging and falling off, etc., to prevent oxidation, facilitate heat dissipation, and maintain high temperature The effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

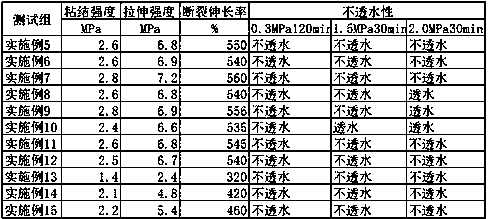

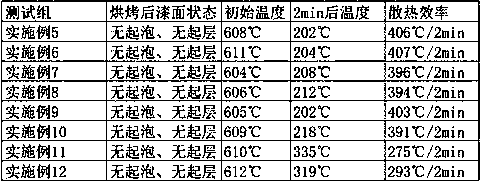

Examples

Embodiment 1

[0029] A high-viscosity polyurethane waterproof coating, made of the following raw materials in parts by weight: 80 parts of polyurethane emulsion, 5 parts of vermiculite powder, 6 parts of cordierite micropowder, 3 parts of lime powder, 6 parts of thermal conductivity additive, fatty alcohol polyoxyethylene 0.45 parts of ether, 2.55 parts of carbomer resin, 5 parts of benzyl alcohol, 1 part of mineral oil liquid powerful defoamer, 1 part of talcum powder and 10 parts of deionized water, wherein the particle size of vermiculite powder is 600 mesh, and cordierite micropowder The particle size is less than 10 μm.

[0030] Described heat conduction aid is low melting point glass powder modified graphene, and the preparation method of low melting point glass powder modified graphene is as follows:

[0031] A. Add low melting point glass powder into deionized water (1g low melting point glass powder / 10ml deionized water), and fully stir in a magnetic stirrer (speed 1000r / min, stirr...

Embodiment 2

[0037] A high-viscosity polyurethane waterproof coating, made of the following raw materials in parts by weight: 45 parts of polyurethane emulsion, 5 parts of vermiculite powder, 6 parts of cordierite micropowder, 3 parts of lime powder, 6 parts of thermal conductivity additive, fatty alcohol polyoxyethylene 0.05 parts of ether, 0.95 parts of carbomer resin, 5 parts of 2,2,4-trimethyl-1,3 pentanediol monoisobutyrate, 0.2 parts of mineral oil liquid powerful defoamer, 2 parts of talc powder and 5 parts of deionized water, wherein the particle size of the vermiculite powder is 800 mesh, and the particle size of the cordierite micropowder is less than 10 μm.

[0038] The heat conduction aid is low melting point glass powder modified graphene, and the preparation method of low melting point glass powder modified graphene is as follows:

[0039] A. Add low melting point glass powder into deionized water (1g low melting point glass powder / 20ml deionized water), fully stir in a magne...

Embodiment 3

[0045]A high-viscosity polyurethane waterproof coating, made of the following raw materials in parts by weight: 90 parts of polyurethane emulsion, 3.5 parts of vermiculite powder, 1.5 parts of cordierite micropowder, 2 parts of lime powder, 2 parts of thermal conductivity additive, fatty alcohol polyoxyethylene 0.5 parts of ether, 4.5 parts of carbomer resin, 2 parts of benzyl alcohol, 0.5 parts of mineral oil liquid strong defoamer, 0.5 part of silicon polyether defoamer, 0.5 part of titanium dioxide and 20 parts of deionized water, of which vermiculite powder The particle size of the cordierite powder is 600 mesh, and the particle size of the cordierite powder is less than 10 μm.

[0046] The heat conduction aid is low melting point glass powder modified graphene, and the preparation method of low melting point glass powder modified graphene is as follows:

[0047] A. Add low melting point glass powder into deionized water (1g low melting point glass powder / 10ml deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com