Low-corrosivity rubber and plastic product and preparation method thereof

A rubber and plastic product, corrosive technology, applied in the field of rubber and plastic products, can solve the problem of high corrosion of metal interface, achieve the effect of reduced corrosion, good mechanical properties, and solve the effect of high corrosion of metal interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

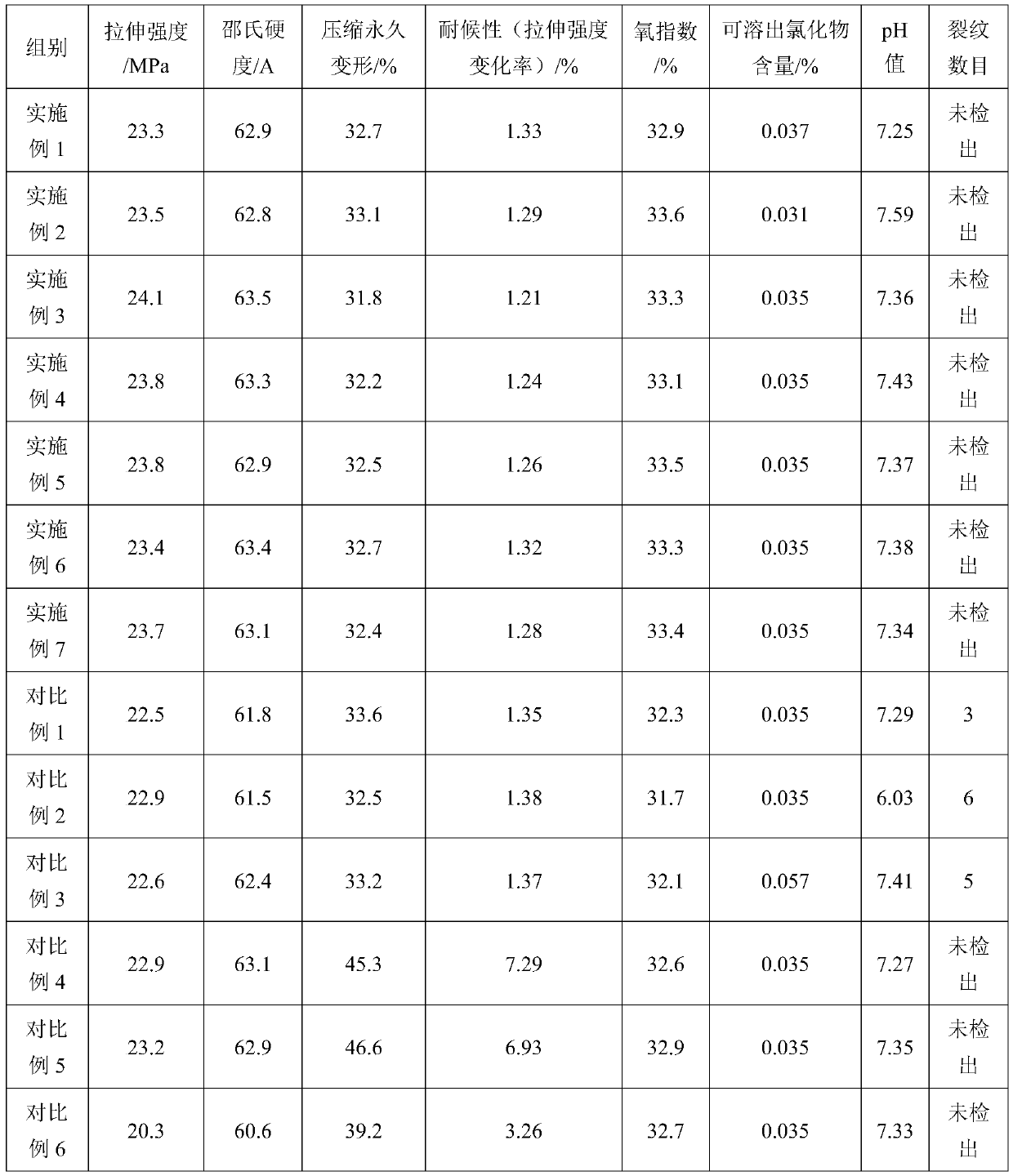

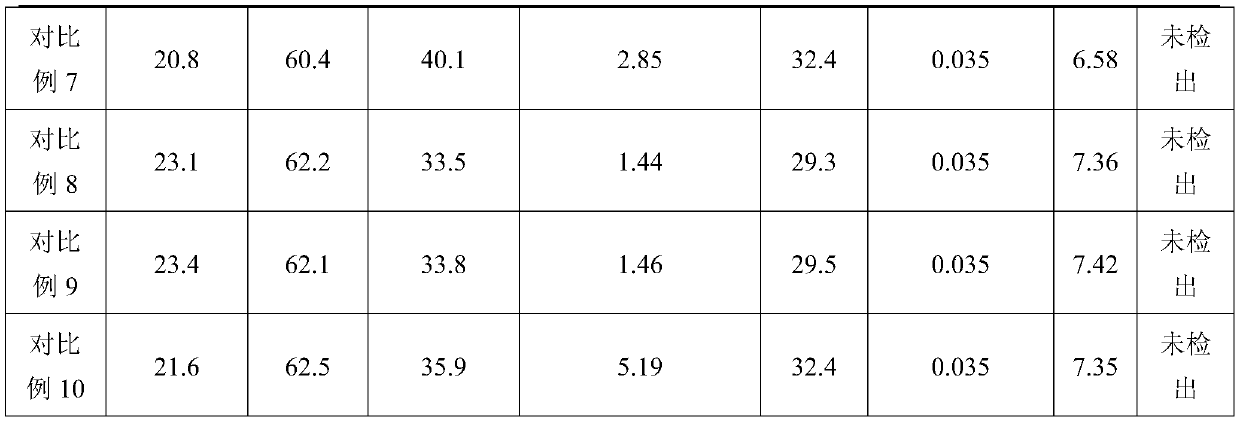

Examples

Embodiment 1

[0032] A low-corrosion rubber and plastic product, comprising the following components by weight:

[0033] 15 parts of nitrile rubber, 5 parts of polyvinyl chloride resin, 3 parts of vinyl acetate copolymer resin, 20 parts of talcum powder, 2 parts of polydimethylsiloxane, 13 parts of plasticizer, 1 part of heat stabilizer, protective 2 parts of wax, 3 parts of carbon black, 0.2 parts of active agent, 0.1 part of stearic acid, 10 parts of flame retardant, 0.1 part of anti-aging agent, 1 part of accelerator, 0.1 part of vulcanizing agent, 4 parts of foaming agent,

[0034] Among them, the vulcanizing agent is 4,4'-dithiodimorpholine, the heat stabilizer is a mixture of molybdenum trioxide and monobutyl phosphate with a mass ratio of 3:1, and the active agent is nano-zinc oxide, hydroxyethylidene The mass ratio of phosphonic acid is a mixture of 2.5:1, the flame retardant is a mixture of aluminum tripolyphosphate and sodium silicate with a mass ratio of 1:1, the anti-aging agent...

Embodiment 2

[0042] A low-corrosion rubber and plastic product, comprising the following components by weight:

[0043] 20 parts of nitrile rubber, 7 parts of polyvinyl chloride resin, 5 parts of vinyl acetate copolymer resin, 30 parts of talcum powder, 7 parts of polydimethylsiloxane, 15 parts of plasticizer, 3 parts of heat stabilizer, protective 4 parts of wax, 5 parts of carbon black, 0.3 part of active agent, 0.3 part of stearic acid, 20 parts of flame retardant, 0.3 part of anti-aging agent, 3 parts of accelerator, 0.3 part of vulcanizing agent, 7 parts of foaming agent,

[0044]Among them, the vulcanizing agent is 4,4'-dithiodimorpholine, the heat stabilizer is a mixture of molybdenum trioxide and monobutyl phosphate with a mass ratio of 3:1, and the active agent is nano-zinc oxide, hydroxyethylidene The mass ratio of phosphonic acid is a mixture of 2.5:1, the flame retardant is a mixture of aluminum tripolyphosphate and sodium silicate with a mass ratio of 1:1, the anti-aging agent...

Embodiment 3

[0047] A low-corrosion rubber and plastic product, comprising the following components by weight:

[0048] 18 parts of nitrile rubber, 6 parts of polyvinyl chloride resin, 4 parts of vinyl acetate copolymer resin, 25 parts of talcum powder, 5 parts of polydimethylsiloxane, 14 parts of plasticizer, 2 parts of heat stabilizer, protective 3 parts of wax, 4 parts of carbon black, 0.25 parts of active agent, 0.2 part of stearic acid, 15 parts of flame retardant, 0.2 part of anti-aging agent, 2 parts of accelerator, 0.2 part of vulcanizing agent, 5 parts of foaming agent,

[0049] Among them, the vulcanizing agent is 4,4'-dithiodimorpholine, the heat stabilizer is a mixture of molybdenum trioxide and monobutyl phosphate with a mass ratio of 3:1, and the active agent is nano-zinc oxide, hydroxyethylidene The mass ratio of phosphonic acid is a mixture of 2.5:1, the flame retardant is a mixture of aluminum tripolyphosphate and sodium silicate with a mass ratio of 1:1, the anti-aging ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com