Electrochemical reaction device and method for synchronously removing total nitrogen in electroplating wastewater

A chemical reaction and electroplating wastewater technology, applied in the field of electrochemistry, can solve the problems of long total processing time and high energy consumption, and achieve the effects of fast speed, simple and reasonable device structure design, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

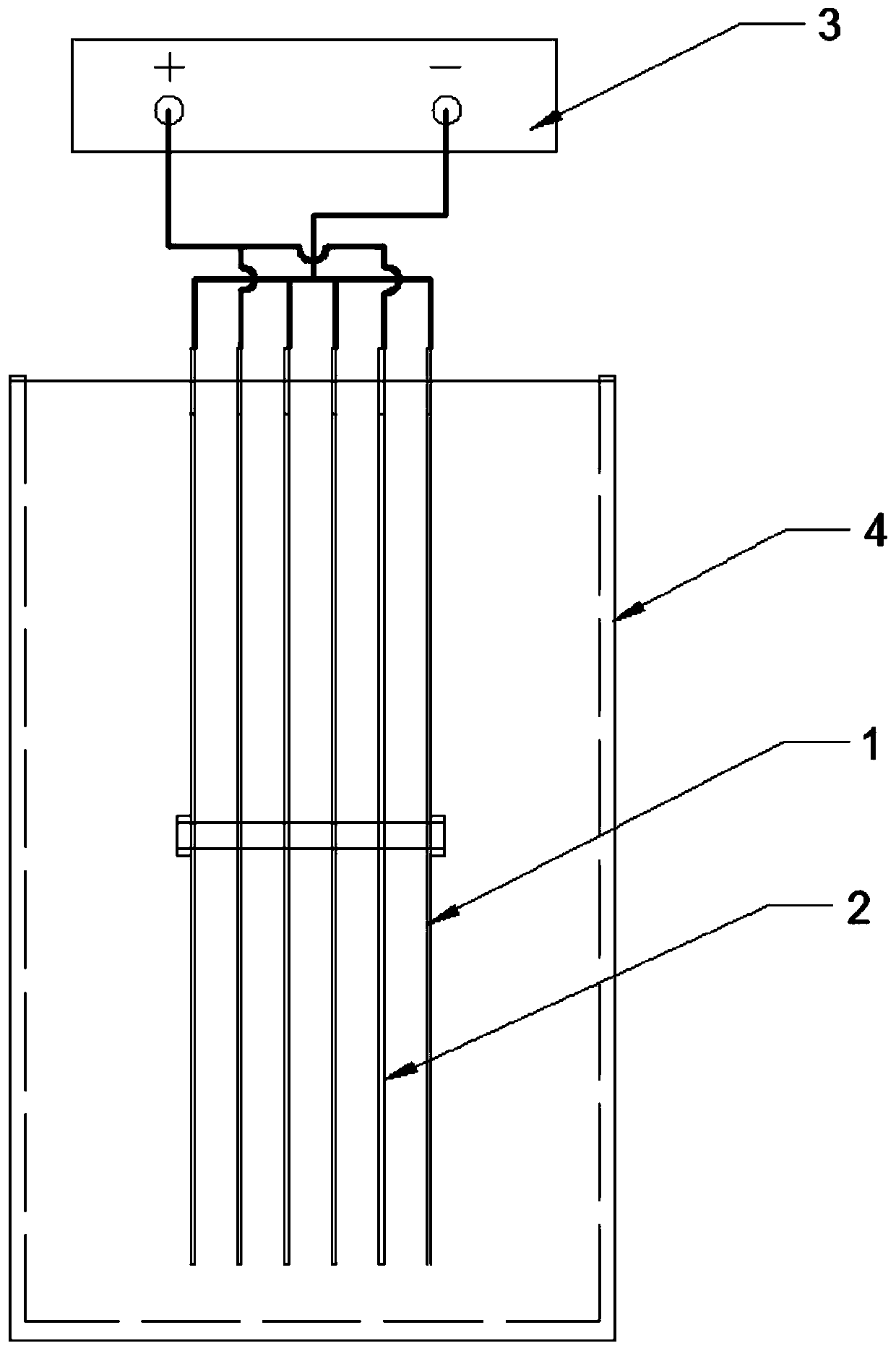

[0081] The cathode is connected to the negative pole of the power supply with three-dimensional nitrogen-doped carbon-loaded foam copper, the anode is connected to the positive pole of the power supply with a titanium ruthenium grid, and the cathode plate and the anode plate are placed at intervals (see attached figure 1 ), the ratio is cathode: anode = 2:1 (4 cathode plates, 2 anode plates), and the distance between the plates is 5mm. Turn on the power, and the hydraulic retention time is 3 hours.

[0082] Influent water quality: initial pH=6.78, conductivity=13.88ms / cm, dissolved oxygen (DO)=12.26mg / L, COD=214mg / L, nitrate nitrogen=80mg / L, ammonia nitrogen=160mg / L, total nitrogen =300mg / L, the current density is set to 5mA / cm 2 .

[0083] After being treated by the electrochemical synchronous denitrification reactor, the nitrate nitrogen is 7.5mg / L, the ammonia nitrogen is 0mg / L, the total nitrogen is 14mg / L, and the total nitrogen removal rate is 95.33%.

Embodiment 2

[0085] The cathode is connected to the negative pole of the power supply with three-dimensional nitrogen-doped carbon-loaded foam copper, the anode is connected to the positive pole of the power supply with a titanium ruthenium grid, and the cathode plate and the anode plate are placed at intervals (see attached figure 1 ), the ratio is cathode: anode = 2:1 (4 cathode plates, 2 anode plates), and the distance between the plates is 5mm. Turn on the power, and the hydraulic retention time is 3 hours.

[0086] Influent water quality: initial pH=6.78, conductivity=13.88ms / cm, dissolved oxygen (DO)=12.26mg / L, COD=214mg / L, nitrate nitrogen=80mg / L, ammonia nitrogen=160mg / L, total nitrogen =300mg / L, the current density is set to 10mA / cm 2 .

[0087] After being treated by the electrochemical synchronous denitrification reactor, the nitrate nitrogen is 4.5mg / L, the ammonia nitrogen is 0mg / L, the total nitrogen is 6.0mg / L, and the total nitrogen removal rate is 98%.

Embodiment 3

[0089]The cathode is connected to the negative electrode of the power supply with three-dimensional nitrogen-doped carbon-loaded foam copper, and the anode is connected to the positive electrode of the power supply with a titanium ruthenium grid. The cathode plate and the anode plate are placed at intervals. According to the low ratio of nitrate nitrogen in the influent, the ratio of the cathode to the anode is adjusted to the cathode: anode = 1:1 (2 cathode plates, 2 anode plates), the distance between the plates is 5mm. Turn on the power, and the hydraulic retention time is 3 hours.

[0090] Influent water quality: initial pH=6.78, conductivity=13.88ms / cm, dissolved oxygen (DO)=12.26mg / L, COD=214mg / L, nitrate nitrogen=35mg / L, ammonia nitrogen=200mg / L, total nitrogen =300mg / L; current density is set to 5mA / cm 2 .

[0091] After being treated by the electrochemical synchronous denitrification reactor, the nitrate nitrogen is 2.5mg / L, the ammonia nitrogen is 0mg / L, the total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com