Metal phase molybdenum disulfide, electrode, preparation method, electrocatalyst and energy storage element

A technology of molybdenum disulfide and metal phase, applied in the field of materials, can solve the problems of low safety, long production cycle, complex equipment, etc., and achieve the effect of simple equipment, short reaction time and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

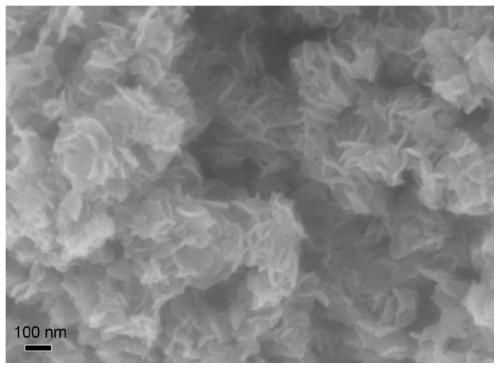

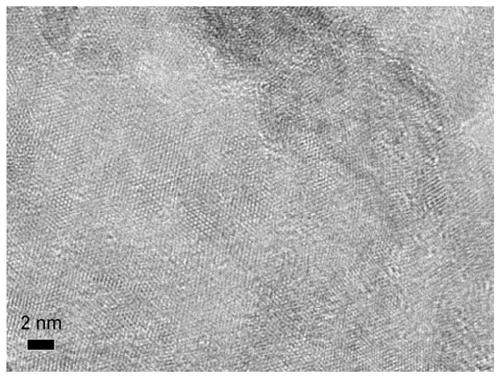

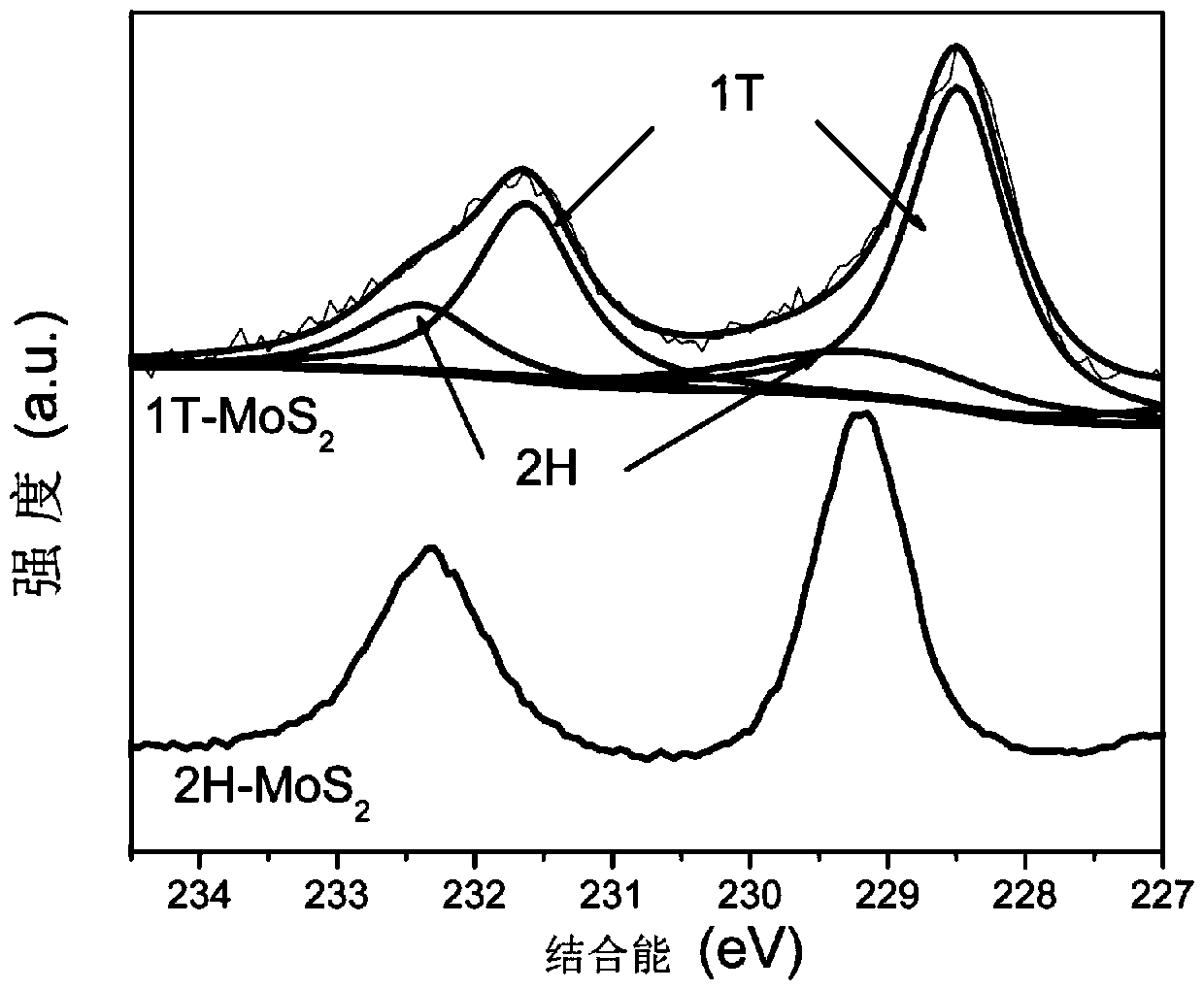

[0049] A metal phase molybdenum disulfide, the specific preparation method is as follows:

[0050] 1) Weigh 0.24g of sodium molybdate and 0.48g of thiourea, dissolve them in 16mL of water, stir to form a homogeneous solution, and obtain the first solution;

[0051] 2) Add 8 mL of propionic acid to the first solution, continue to stir until the mixture is evenly mixed to obtain a mixed solution, then transfer the mixed solution to a 50 mL reaction kettle, seal it, and conduct a hydrothermal reaction in an oven at 180°C for 4 hours;

[0052] 3) Naturally cool to room temperature after the hydrothermal reaction, centrifuge the obtained solid product, wash it several times with deionized water and ethanol respectively, collect the solid product, and dry it in vacuum to obtain metal phase molybdenum disulfide powder.

Embodiment 2

[0054] A metal phase molybdenum disulfide, the specific preparation method is as follows:

[0055] 1) Weigh 0.24g of sodium molybdate and 0.48g of thiourea, dissolve them in 16mL of water, stir to form a homogeneous solution, and obtain the first solution;

[0056] 2) Add 6 mL of acetic acid to the first solution, continue to stir until the mixture is evenly mixed to obtain a mixed solution, then transfer the mixed solution to a 50 mL reaction kettle, and conduct a hydrothermal reaction in an oven at 180°C for 4 hours after sealing;

[0057] 3) Naturally cool to room temperature after the hydrothermal reaction, centrifuge the obtained solid product, wash it several times with deionized water and ethanol respectively, collect the solid product, and dry it in vacuum to obtain metal phase molybdenum disulfide powder.

Embodiment 3

[0059] A self-supporting structure electrode, the specific preparation method is as follows:

[0060] 1) Weigh 0.024g of sodium molybdate and 0.048g of thiourea, dissolve them in 10mL of water, stir to form a homogeneous solution, and obtain the first solution;

[0061] 2) Add 5mL propionic acid to the first solution, continue to stir until the mixture is evenly mixed to obtain a mixed solution, then transfer the mixed solution to a 50mL reactor, and then add carbon cloth into the reactor as a base material, after the reactor is closed Hydrothermal reaction in an oven at 180°C for 8 hours;

[0062] 3) Naturally cool to room temperature after the hydrothermal reaction, take out the carbon cloth, wash it with ethanol several times, and dry it in vacuum to obtain a self-supporting structure electrode, which includes carbon cloth and a metal phase grown on the carbon cloth Molybdenum disulfide self-supporting structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com