Electric firing device

A firing device and electromagnetic device technology, applied in the direction of nailing U-shaped nail tools, nailing tools, manufacturing tools, etc., can solve the problems of high overall structure height, speaker noise, and large volume, so as to reduce the structure volume and reduce operating noise , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples illustrate possible implementations of the present invention, but they are not intended to limit the protection scope of the present invention and are stated in advance.

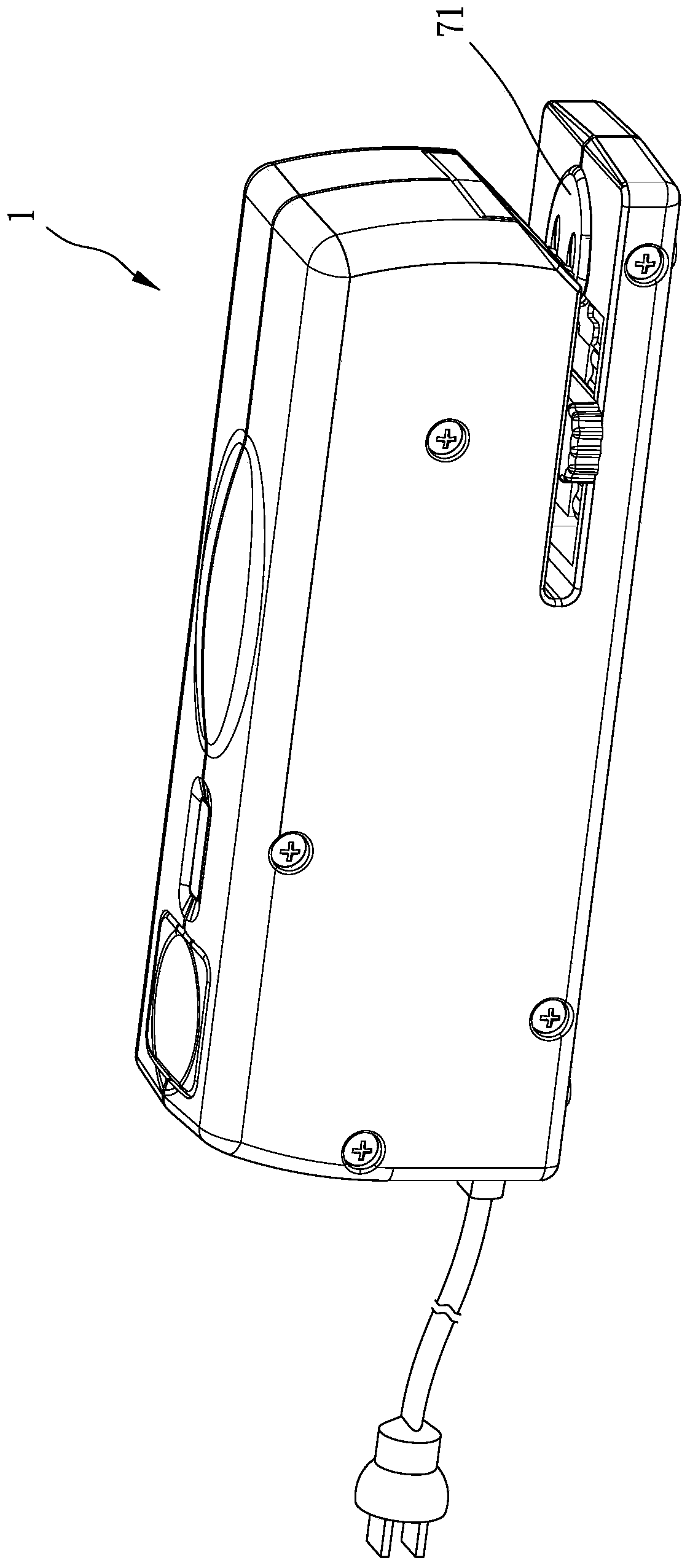

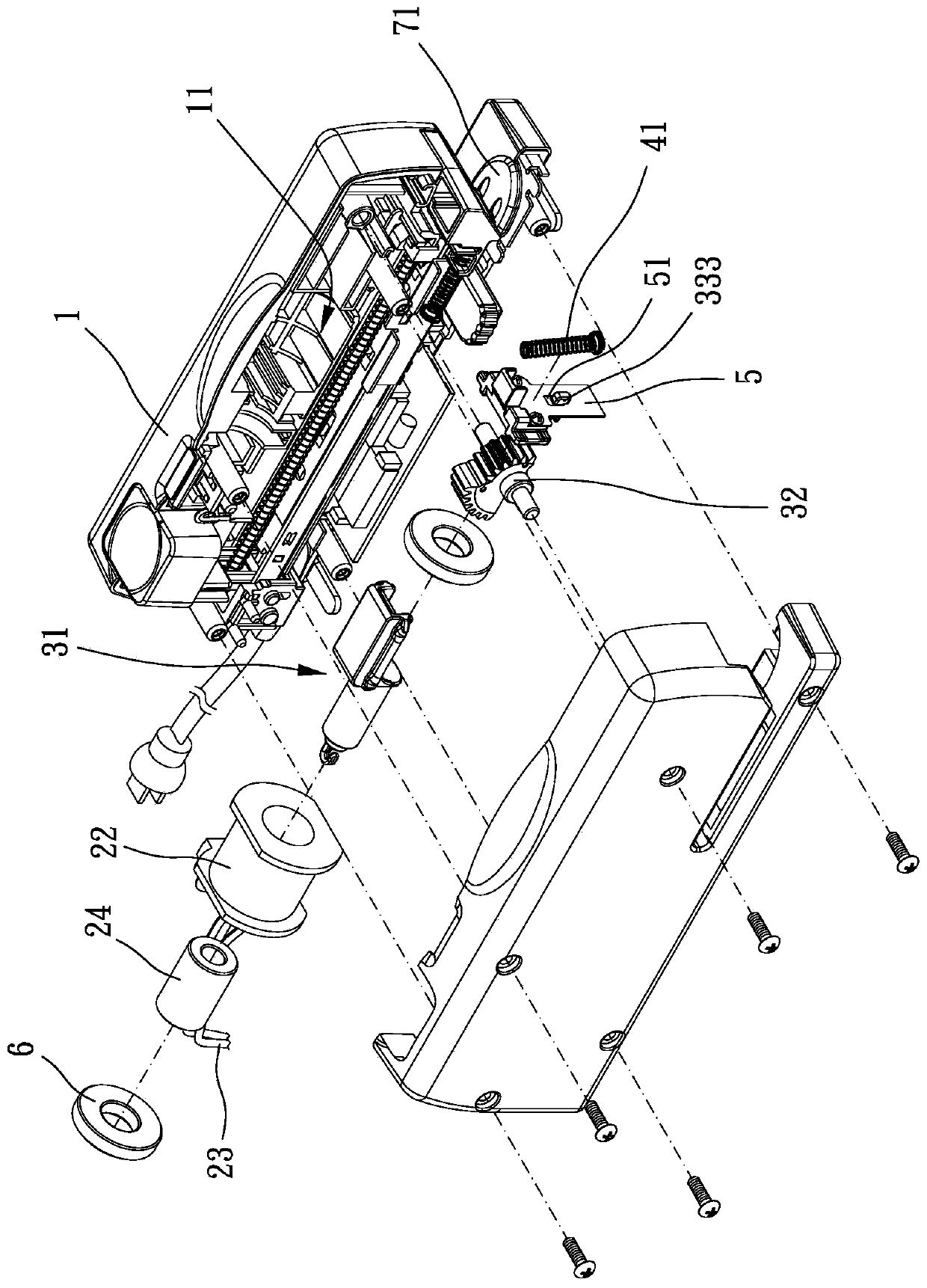

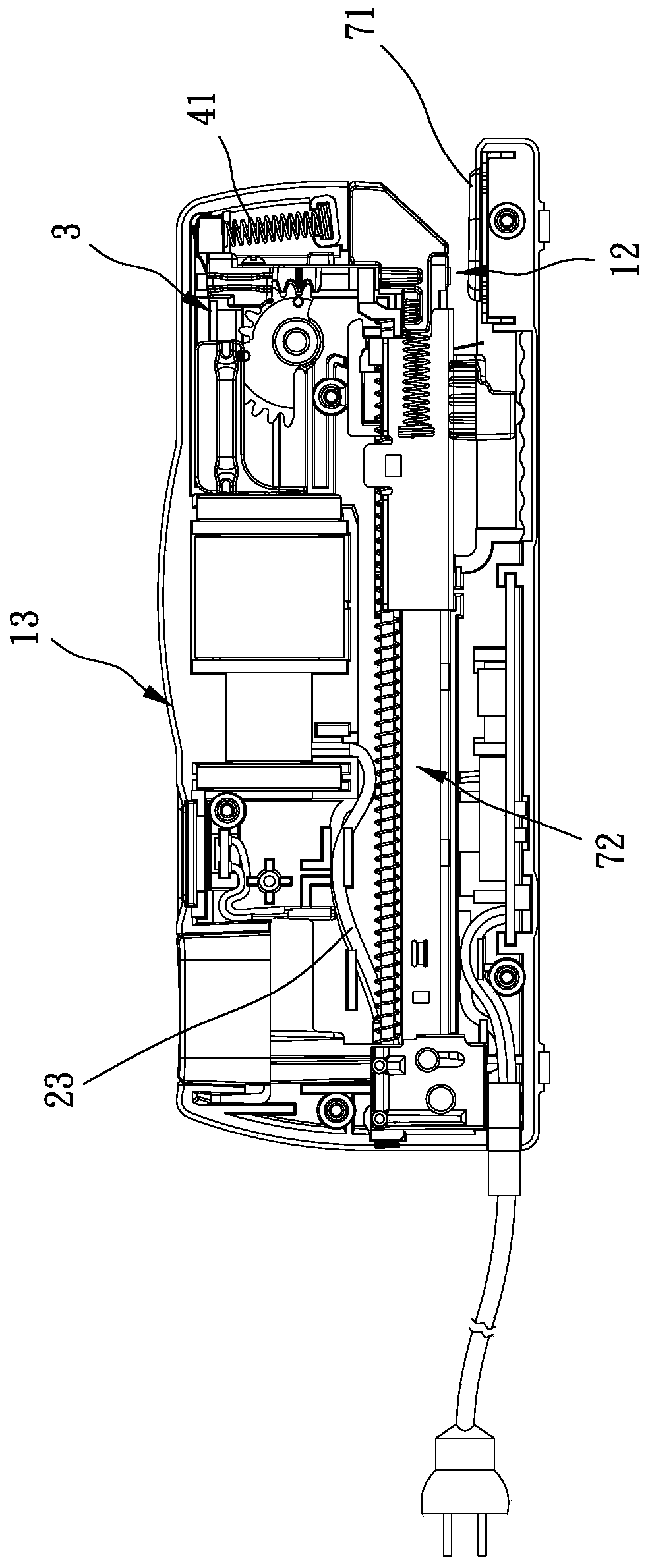

[0016] Please refer to Figure 1 to Figure 6 , which shows a first embodiment of the present invention, the electric firing device of the present invention includes a body 1 and a firing unit 2 .

[0017] The main body 1 includes an inner space 11 and a firing port 12 . The firing unit 2 is located in the internal space 11, and the firing unit 2 includes an electromagnetic device 21, a driving member 24, a steering mechanism 3 and a striking member 5, and the electromagnetic device 21 can generate magnetic force to drive The driving member 24 moves along the opening direction transverse to the firing port 12, that is, the direction of the magnetic field generated by the electromagnetic device 21 is transverse to the opening direction of the firing port 12, and the impact member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com