Mesh belt screen with high-molecular ring belt plane-rotation movement screen surface and manufacturing method of special mesh belt

A polymer and sieve surface technology, applied in chemical instruments and methods, filtration, solid separation, etc., can solve problems such as easy clogging of the sieve surface, weakened sieving effect, broken sieve, etc., to ensure motion stability, sieve The effect of increasing the handling efficiency and smoothing the contact position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

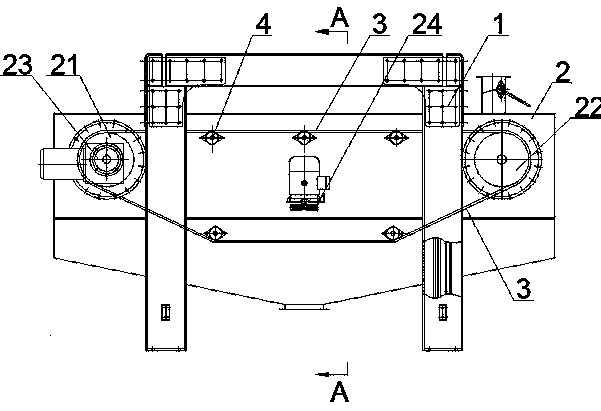

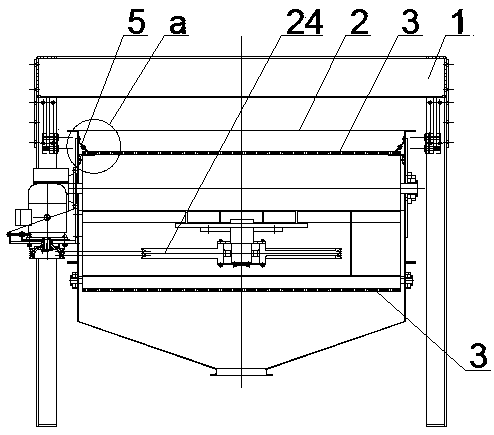

[0044] A mesh belt sieve with a polymer ring belt and a horizontally moving screen surface, which consists of: an overall frame of the equipment 1, a screen box 2 hinged on the frame, and a head wheel 21 and a tail wheel are installed in the screen box. Wheel 22, the head wheel is connected to the rotating drive device 23, and the polymer ring belt screen surface 3 is set on the head wheel 21 and the tail wheel 22 as a conveyor belt, driving the screen surface to circle between the head wheel and the tail wheel The sieve box is connected to the horizontal return drive device 24 to make the sieve box do a plane rotary motion. The screen surface of the polymer ring belt has sieving holes 31, and the two sides of the screen surface of the polymer ring belt There is a non-porous anti-wear zone 32, the non-porous anti-wear zone is 15-100 mm wide, such as 15, 20, 30, 40, 50, 60, 70, 80, 90, 100 mm, the wider the screen surface, the wider the The width of the anti-wear zone of the ho...

Embodiment 2

[0046] The mesh belt screen with the polymer ring belt flat back movement screen surface described in Example 1, the polymer ring belt can be a polyurethane screen surface or a composite screen surface with reinforcing ribs, and the composite screen surface It includes a tensile layer with reinforcing ribs and a surface layer 33, the tensile layer is metal or organic tensile wire 34 or base cloth 35, and the surface layer is a latex or rubber adhesive layer or polyurethane coating. The supporting rollers are arranged horizontally or vertically, and the direction of the supporting rollers is perpendicular to the moving direction of the sieve or consistent with the moving direction of the screen surface

Embodiment 3

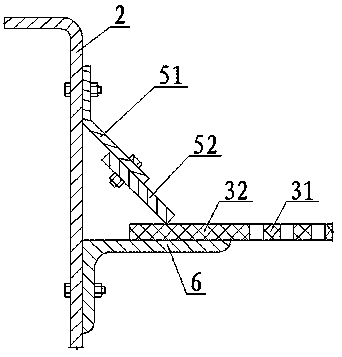

[0048] In the mesh belt screen with a polymer ring belt flat back moving screen surface described in embodiment 1 or 2, material blocking plates 5 are connected to the box plates on both sides of the screen box to prevent materials from falling from both sides of the screen surface. One end of the material blocking plate is fixed on the screen box, and the other end is lapped on the non-porous wear-resistant area 32 of the polymer ring belt screen surface. The lower part of the blocking plate has a bracket 6, the cross-section of the bracket is L-shaped, one side of the L-shaped bracket is connected to the side wall of the screen box, and the other side supports the non-porous anti-wear area of the screen surface .

[0049] The material blocking plate includes a v-shaped steel plate 51 and a wear-resistant organic plate 52, the wear-resistant organic plate is fixed on one side of the v-shaped steel plate 51 by bolts, and the other side of the v-shaped steel plate is fixed on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com