Wet clutch hydraulic system thermal resistance network model and average temperature estimation method

A wet clutch, hydraulic system technology, applied in the direction of brake type, transmission parts, design optimization/simulation, etc., can solve the problems of limited wide application, large manpower consumption, material and financial resources, poor versatility, etc., to achieve accurate measurement, universal Good sex, the effect of overcoming delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described below in conjunction with accompanying drawing and embodiment:

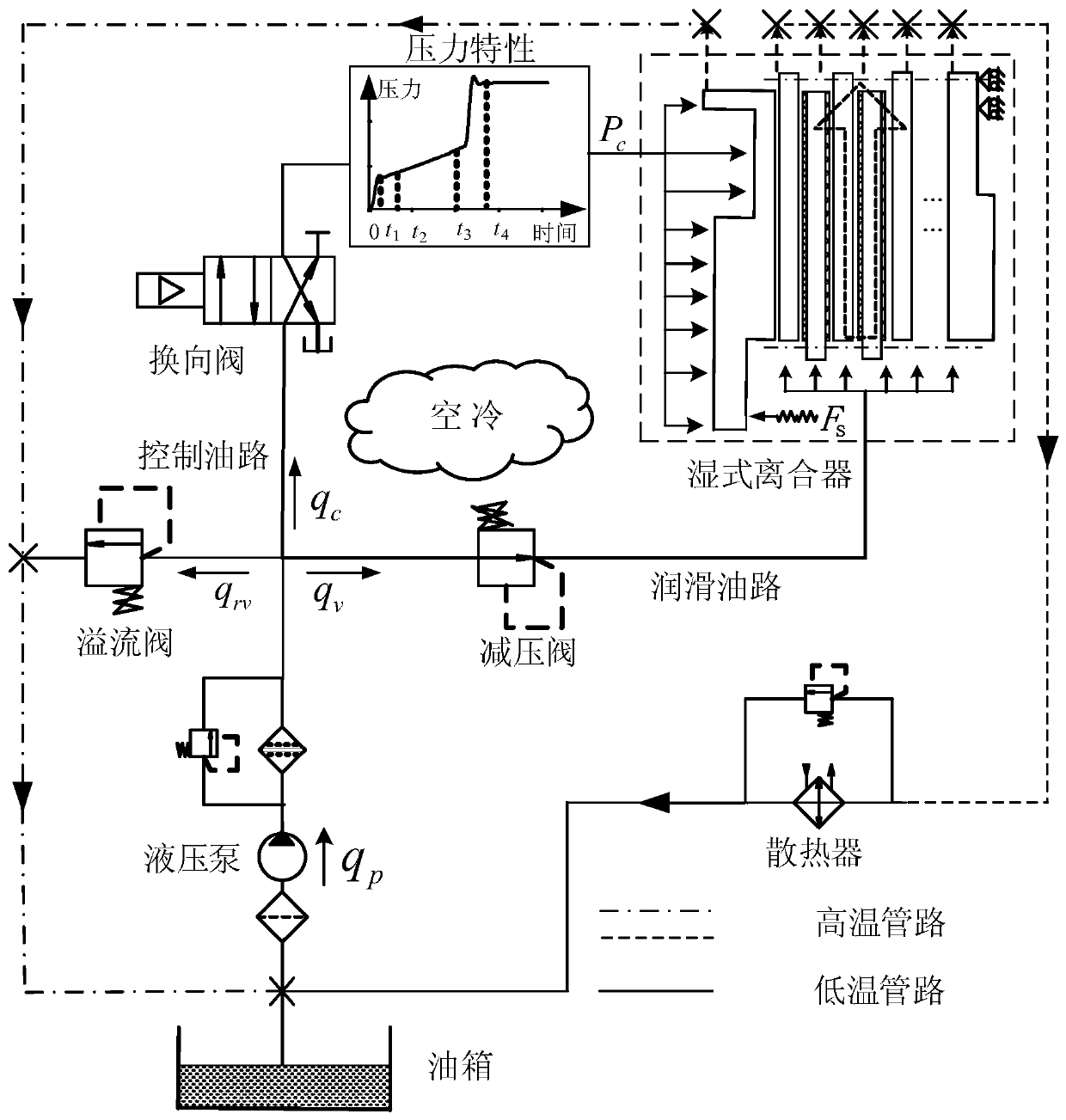

[0037] like figure 1 As shown, the wet clutch hydraulic system can be divided into control oil circuit and lubricating oil circuit. In the control oil circuit, the oil in the oil tank enters the wet clutch piston cylinder from the hydraulic pump through the reversing valve to control the engagement and separation of the wet clutch; when the oil pressure on the piston is established, the excess oil will pass through the piston hole It flows directly back to the oil tank; the oil flowing out of the hydraulic pump is connected with the excess oil circuit through a relief valve. In the lubricating oil circuit, the oil flows through the pressure reducing valve to the gap of the friction pair for cooling and lubrication, and the oil in this circuit flows back to the oil tank after being cooled by the radiator.

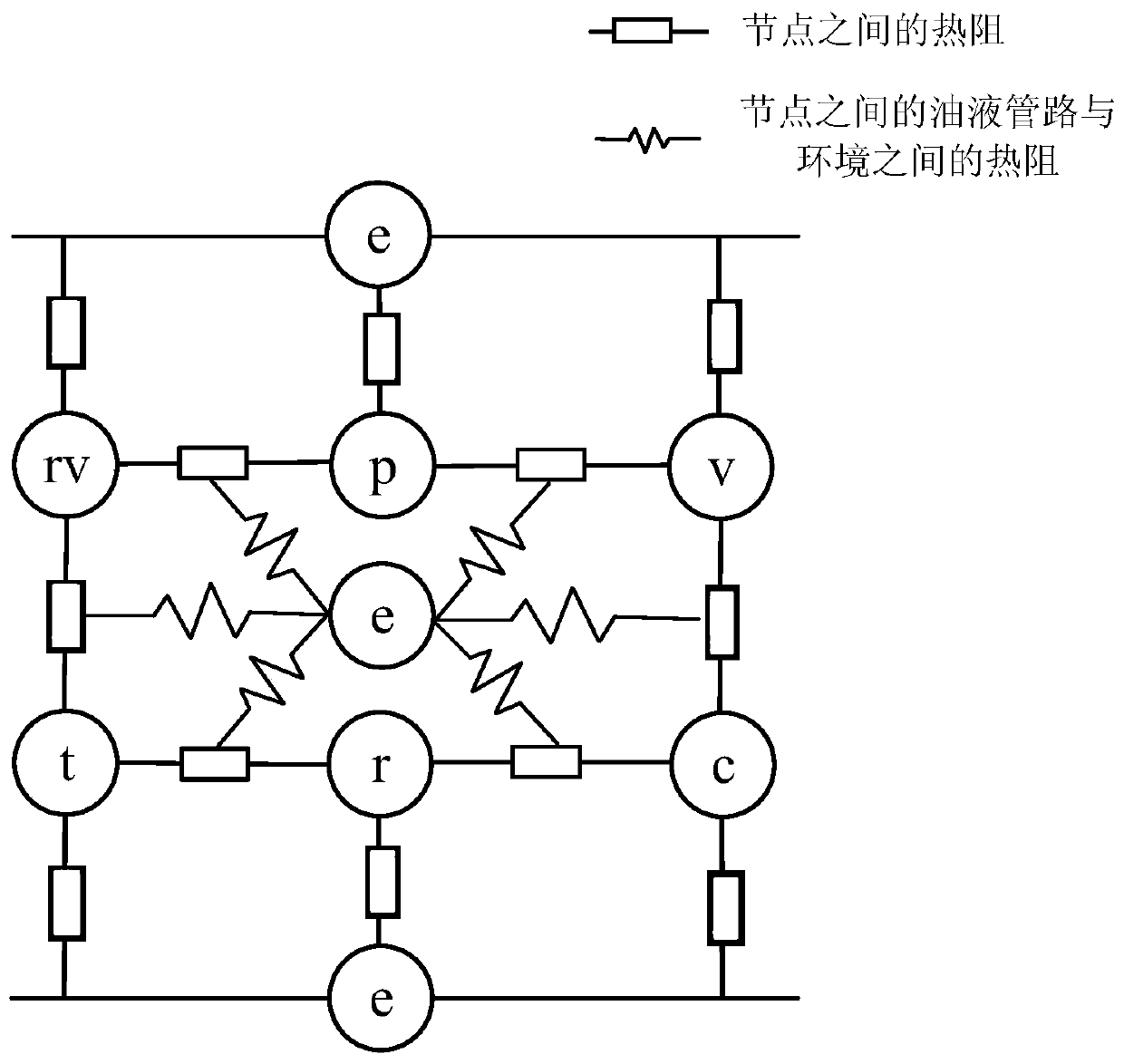

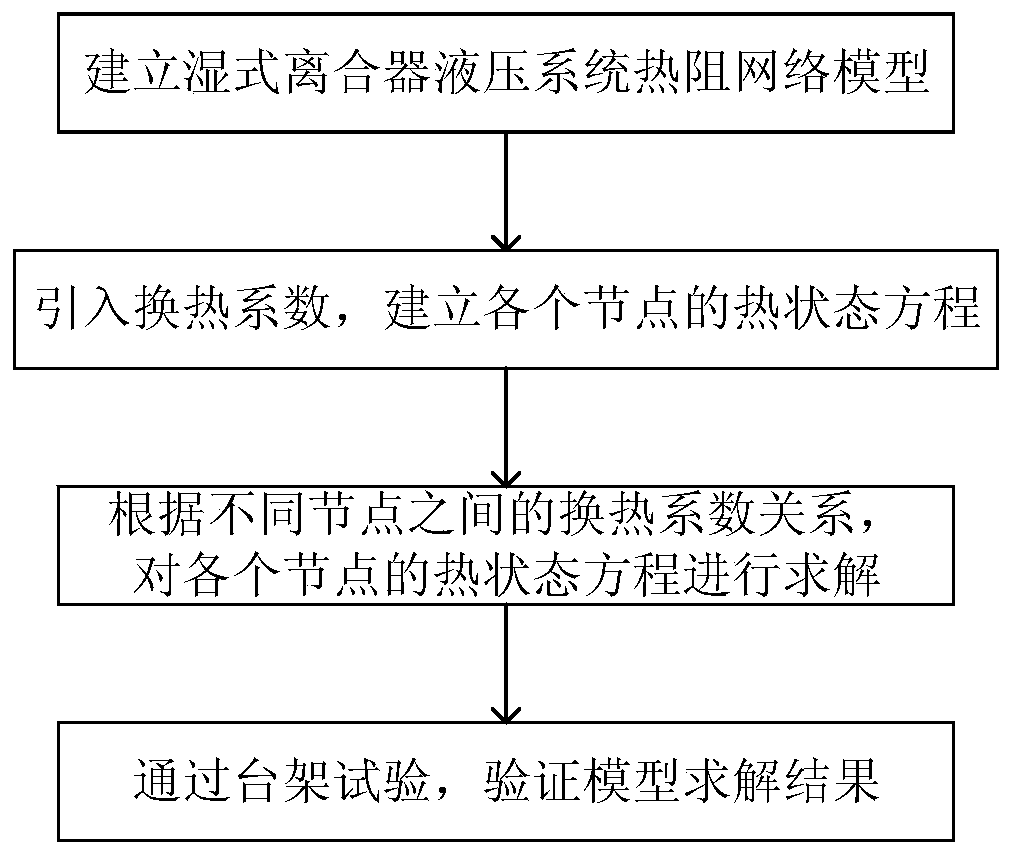

[0038] like figure 2 As shown, in the heat transfer pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com