Method for controlling air input of engine by oxygen sensor signal

A technology of oxygen sensor and control method, which is applied in the direction of engine control, machine/engine, electrical control, etc., can solve problems such as powerlessness, and achieve the effects of precise air-fuel ratio control, overcoming hysteresis response, and precise fuel injection pulse width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Attached below Figure 1-3 The control method for automatically adjusting the air intake of the engine of the present invention is described further:

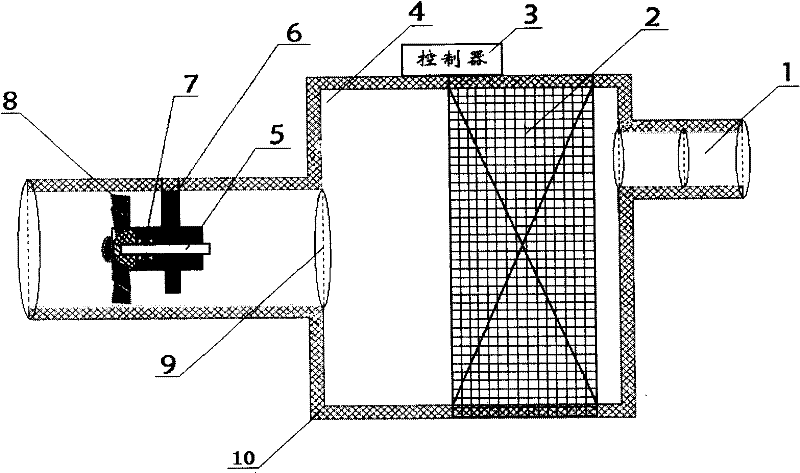

[0023] like figure 1 As shown: the air intake assembly in the figure is composed of an air intake channel opening 1, an air filter 2, a controller 3, an air flow chamber 4, a fan 5, an air flow channel opening 9 and a housing 10; among them, the fan 5 is composed of a fan bracket 6. The speed regulating motor 7 and the fan blade 8 are composed; the external air enters the air filter 2 through the air inlet channel port 1, the air filter 2 purifies and filters the incoming gas, passes through the air flow chamber 4, and passes through the air flow channel port 9 into the engine; the controller 3 is connected with the speed regulating motor 7 of the fan 4.

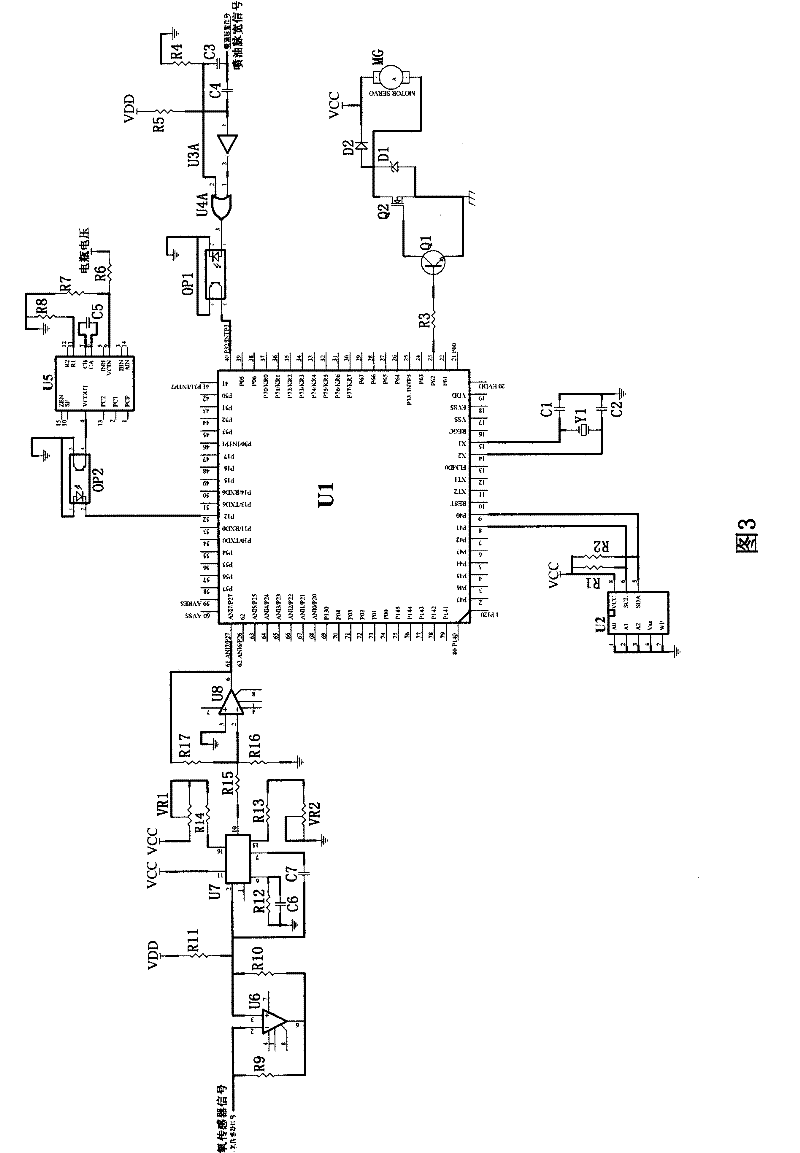

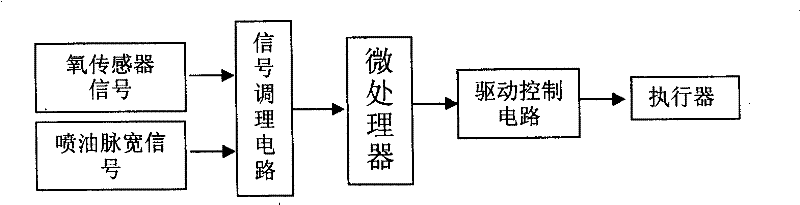

[0024] like image 3 As shown: the controller is composed of microprocessor U1 and its peripheral circuits. The microprocessor is a single-chip microcomputer with b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com