Dual-energy heating type non-scaling type heat storage water tank

A hot water storage tank, heating type technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of bacteria breeding, water pollution, heating efficiency, etc., to avoid scale and stabilize air pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

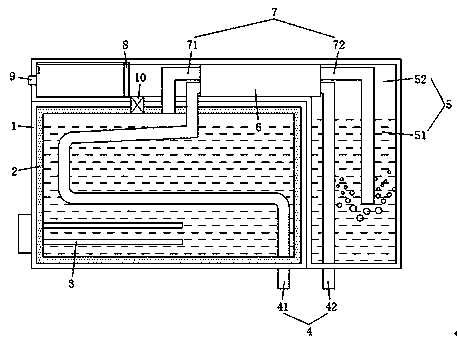

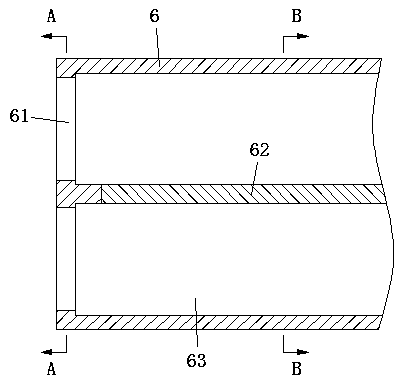

[0029] see Figure 1-Figure 4 As shown, the technical solution provided in this embodiment is: a dual-energy heating type non-fouling hot water storage tank, the hot water storage tank includes a heating box 1, and an insulation layer 2 is provided on the inner wall of the heating box 1;

[0030] A heat exchange tube 4 runs through the inside of the heating box 1, and the two ends of the heat exchange tube 4 are respectively connected with a cold water pipe and a hot water pipe for conducting tap water to be heated;

[0031] There is inherent liquid stored in the heating box 1, and some pipes of the heat exchange tube 4 are immersed in the inherent liquid, and the inherent liquid is demineralized water, so as to ensure that the inherent liquid will not have scale after heating;

[0032] A heating device 3 is also installed in the heating box 1, and the heating device 3 is located in the inherent liquid to heat the inherent liquid; the heating device 3 includes a photovoltaic h...

Embodiment 2

[0038] see Figure 1-Figure 4 As shown, the technical solution provided by this embodiment is: a dual-energy heating type non-fouling hot water storage tank, the hot water storage tank includes a heating tank 1 and a circulation tank 5, wherein the structure of the heating tank 1 is the same as that of the first embodiment In addition, regarding the circulation box 5, it includes: a liquid storage part 51 and an air pressure buffer part 52, the liquid storage part 51 is located below the air pressure buffer part 52, and the inherent liquid is stored in the liquid storage part 51;

[0039] In this embodiment, the air outlet end of the air pipe 7 extends into the liquid storage part 51, the liquid inlet end of the one-way liquid replenishment pipe 10 extends into the air pressure buffer part 52, and the one-way liquid replenishment pipe 10 is composed of the liquid replenishment pipe and installed on the The one-way valve in the liquid replenishment pipe is formed.

[0040] Reg...

Embodiment 3

[0048] This embodiment is a further preferred solution of Embodiment 2, specifically: an air pressure buffer device is also installed in the air pressure buffer part 52, and the air pressure buffer device includes a piston 8 and an exhaust pipe 9, and the piston 8 is located between the exhaust pipe 9 and the one-way Between the liquid replenishment pipes 10, the reciprocating movement is performed based on the air pressure change in the circulation box 5.

[0049] Based on this, in this embodiment, the isolation of the air pressure buffer part 52 from the outside air can be realized, so that the water vapor will not leak out if the water vapor is not condensed in time, and at the same time, it still ensures the air pressure inside the overall hot water storage tank. The stability of air pressure.

[0050] Specifically, its working principle is:

[0051] When water vapor does not condense in time, figure 1 The air pressure in the area on the right side of the middle piston 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com