Composite material skin and preparation method thereof

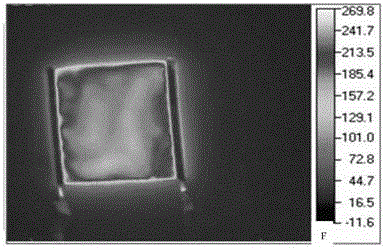

A composite material and skin technology, which is applied in the field of polyimide-fiber reinforced composite skin and its preparation, can solve the problems of high environmental noise, high energy consumption, air pollution, etc., and achieve high heating efficiency and high heating performance Excellent, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] As an embodiment of the present invention, the preparation method of the composite skin comprises the following steps:

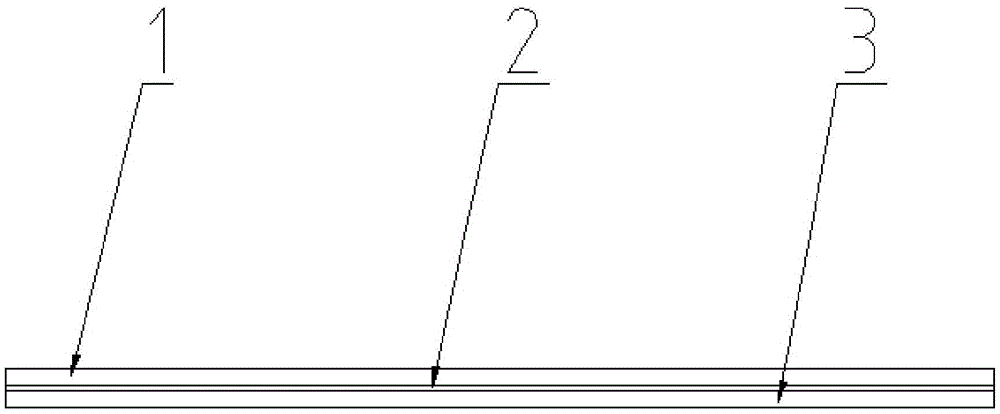

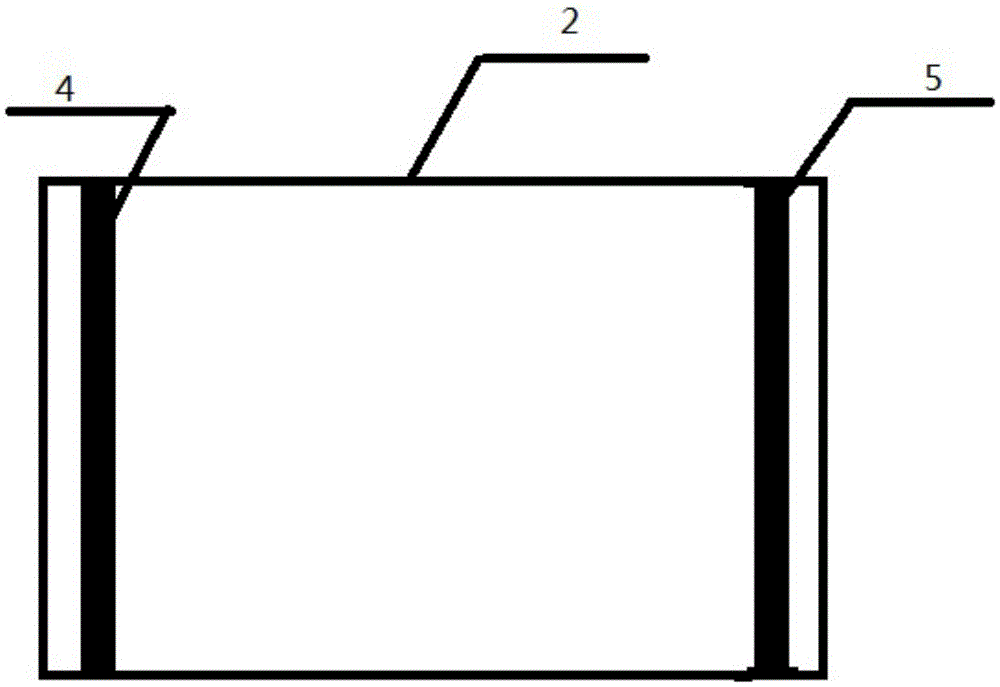

[0036] 1) Use screen printing technology at both ends of the conductive carbon black-polyimide film to print the conductive silver paste into electrodes, such as figure 2 As shown, one end of the electrode is connected to the positive electrode wire by welding, and the other end of the electrode is connected to the negative electrode wire by welding, as shown in image 3 shown.

[0037] 2) The lower fiber-reinforced layer brushed with adhesive, the conductive carbon black-polyimide film and the upper fiber-reinforced layer brushed with adhesive are neatly stacked on the press from bottom to top according to the design requirements On the steel plate, a laminated sandwich structure is obtained.

[0038] The lower fiber reinforced layer is a glass fiber cloth prepreg, the upper fiber reinforced layer is a glass fiber cloth prepreg, and the resin matr...

Embodiment 2

[0041] As an embodiment of the present invention, the preparation method of the composite skin comprises the following steps:

[0042] 1) Use screen printing technology at both ends of the conductive graphene-polyimide film to print the conductive silver paste into electrodes, such as figure 2 As shown, one end of the electrode is connected to the positive electrode wire by welding, and the other end of the electrode is connected to the negative electrode wire by welding, as shown in image 3 shown.

[0043] 2) The lower fiber-reinforced layer brushed with adhesive, the conductive graphene-polyimide film and the upper fiber-reinforced layer brushed with adhesive are neatly stacked on the press from bottom to top according to the design requirements On the steel plate, a laminated sandwich structure is obtained.

[0044] The lower fiber reinforced layer is carbon fiber cloth prepreg, the upper fiber reinforced layer is carbon fiber cloth prepreg, and the resin matrix of the ...

Embodiment 3

[0047] As an embodiment of the present invention, the preparation method of the composite skin comprises the following steps:

[0048] 1) Use screen printing technology at both ends of the conductive carbon nanotube-polyimide film to print the conductive silver paste into electrodes, such as figure 2 As shown, one end of the electrode is connected to the positive electrode wire by welding, and the other end of the electrode is connected to the negative electrode wire by welding, as shown in image 3 shown.

[0049] 2) The lower fiber-reinforced layer brushed with adhesive, the conductive carbon nanotube-polyimide film and the upper fiber-reinforced layer brushed with adhesive are neatly stacked on the press from bottom to top according to the design requirements. On the steel plate of the machine, a laminated sandwich structure is obtained.

[0050] The lower fiber reinforced layer is glass fiber cloth prepreg, the upper fiber reinforced layer is glass fiber cloth prepreg, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com