A construction method of tunnel blasting in complex layered rock strata

A construction method and rock formation technology are applied in the construction field of tunnel blasting in complex layered rock formations, and can solve the problems of large disturbance damage of surrounding rock, rock layer spalling, and discontinuity of surrounding rock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

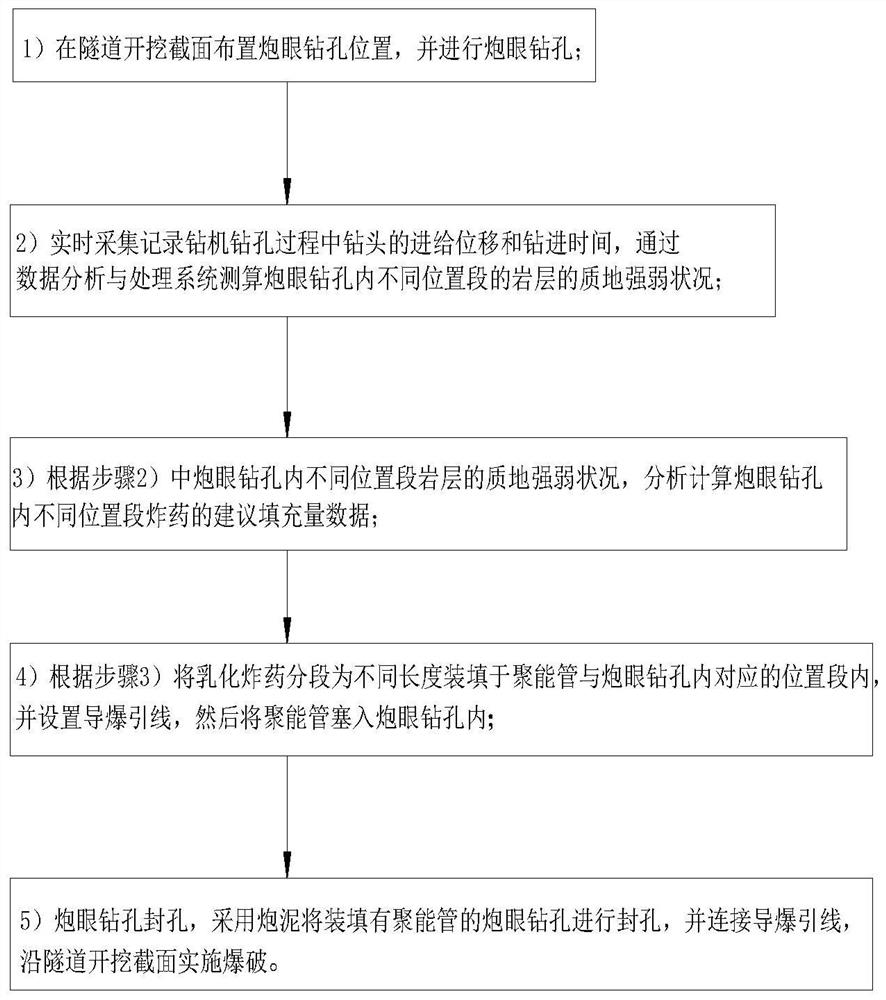

[0029] Embodiment: A kind of construction method of tunnel blasting in complex layered rock layer, such as figure 1 , figure 2 and image 3 As shown, it specifically includes the following steps:

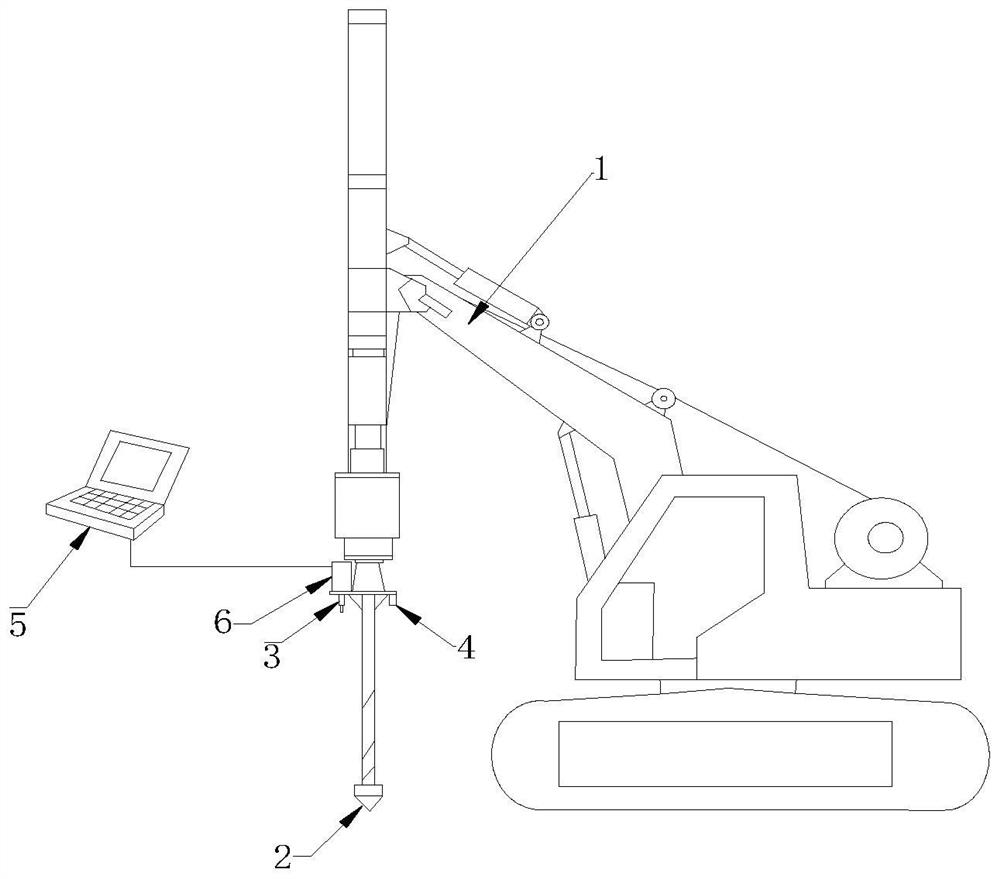

[0030] 1) According to the tunnel excavation and blasting construction plan, the blasthole drilling position is arranged on the tunnel excavation section, and then according to the arranged blasthole drilling position, the drilling rig 1 is used for blasthole drilling;

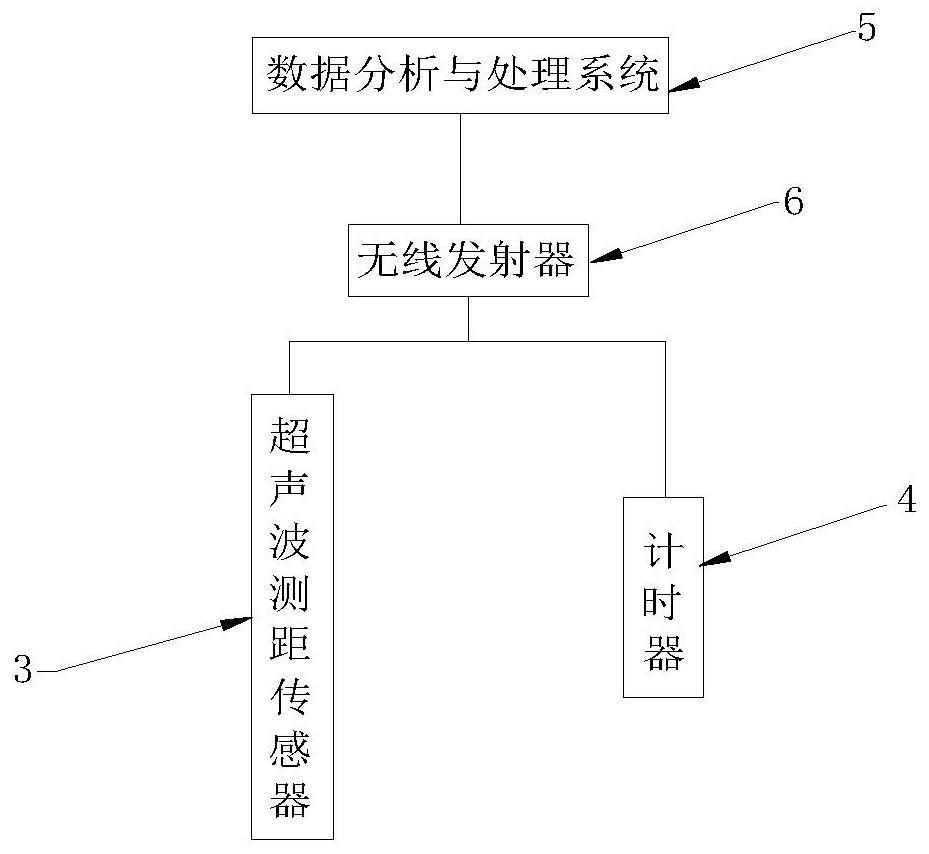

[0031] 2) While drilling in step 1), under the condition that the thrust and rotating speed of the drilling rig 1 are constant, the ultrasonic distance measuring sensor 3 and the timer 4 installed on the drilling rig 1 monitor and record the drill bit 2 of the drilling rig 1 in real time respectively. Feed displacement and drilling time, and transmit the real-time monitoring and recording of the feed displacement and drilling time data information of the drill bit 2 of the drilling rig 1 to the data analysis and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com