Crystallization and purification process of high-purity ethylene carbonate

A technology of crystallization of ethylene carbonate, applied in the crystallization and purification process field of high-purity ethylene carbonate, can solve the problems of low yield, high energy consumption, low product purity, etc., achieve improved purity, mild process, improved purity and Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

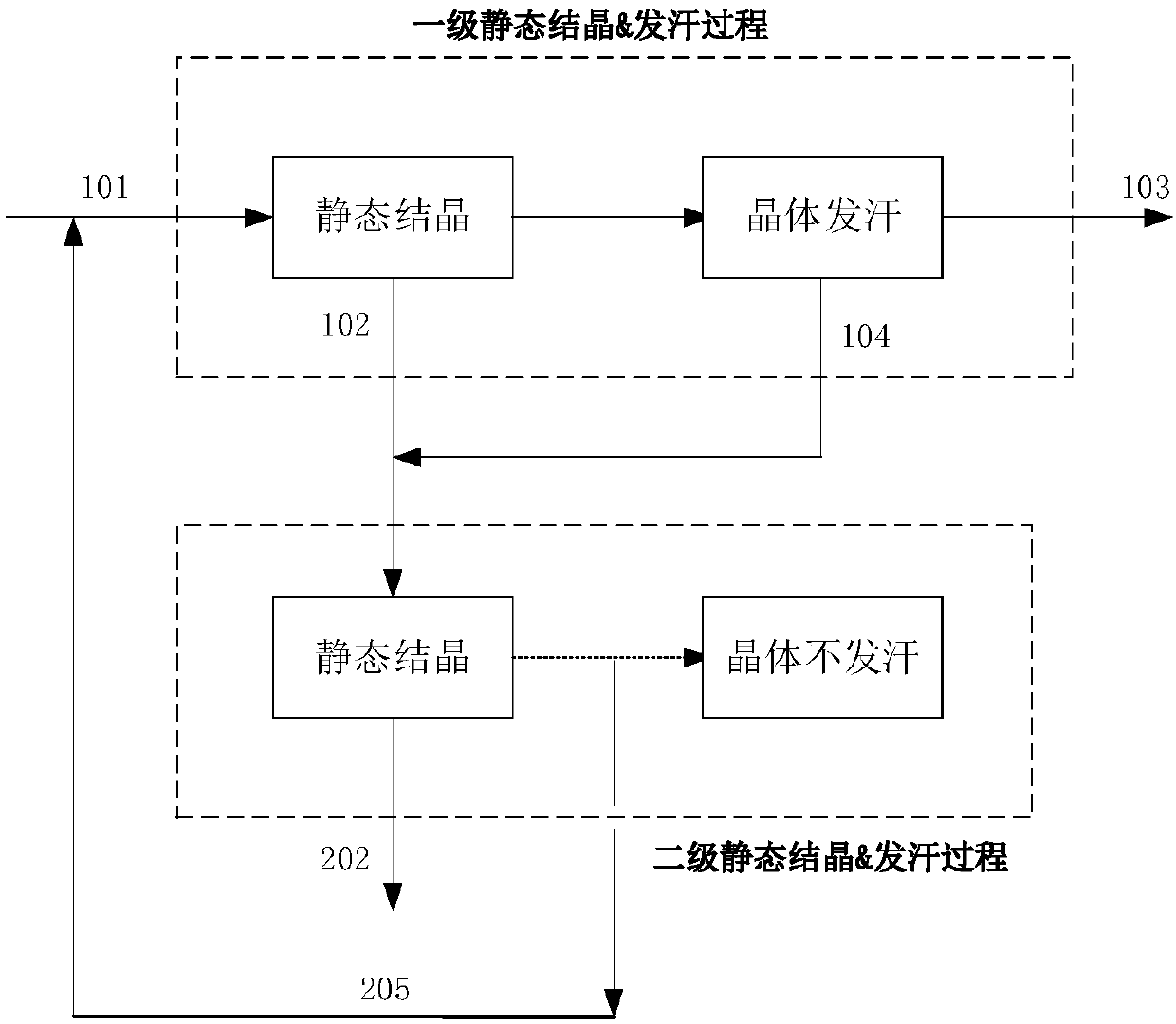

[0043] according to figure 1 As shown in the flow process, the weight percent composition is ethylene carbonate 90.15%, ethylene glycol 6.23%, and other 3.62% EC raw materials are preheated and melted, and then added such as Figure 4 The first-stage static crystallization is carried out in the static crystallizer shown, in which the number of internal heat exchange tubes is 1, and the support on the heat exchange tubes is a single-layer stainless steel wire mesh, whose height is equal to the liquid level in the crystallizer. The external jacket is kept at a constant temperature of 34°C, the seed crystal addition temperature is 34°C, the internal heat exchange tube is cooled by program, the cooling rate is 0.01°C / min, the crystallization end point temperature is 15°C, and the crystallization is stopped after 60 minutes at the end point temperature, and the drain at the bottom of the static crystallizer is opened At the feeding port, the sweating of the crystals begins after th...

Embodiment 2

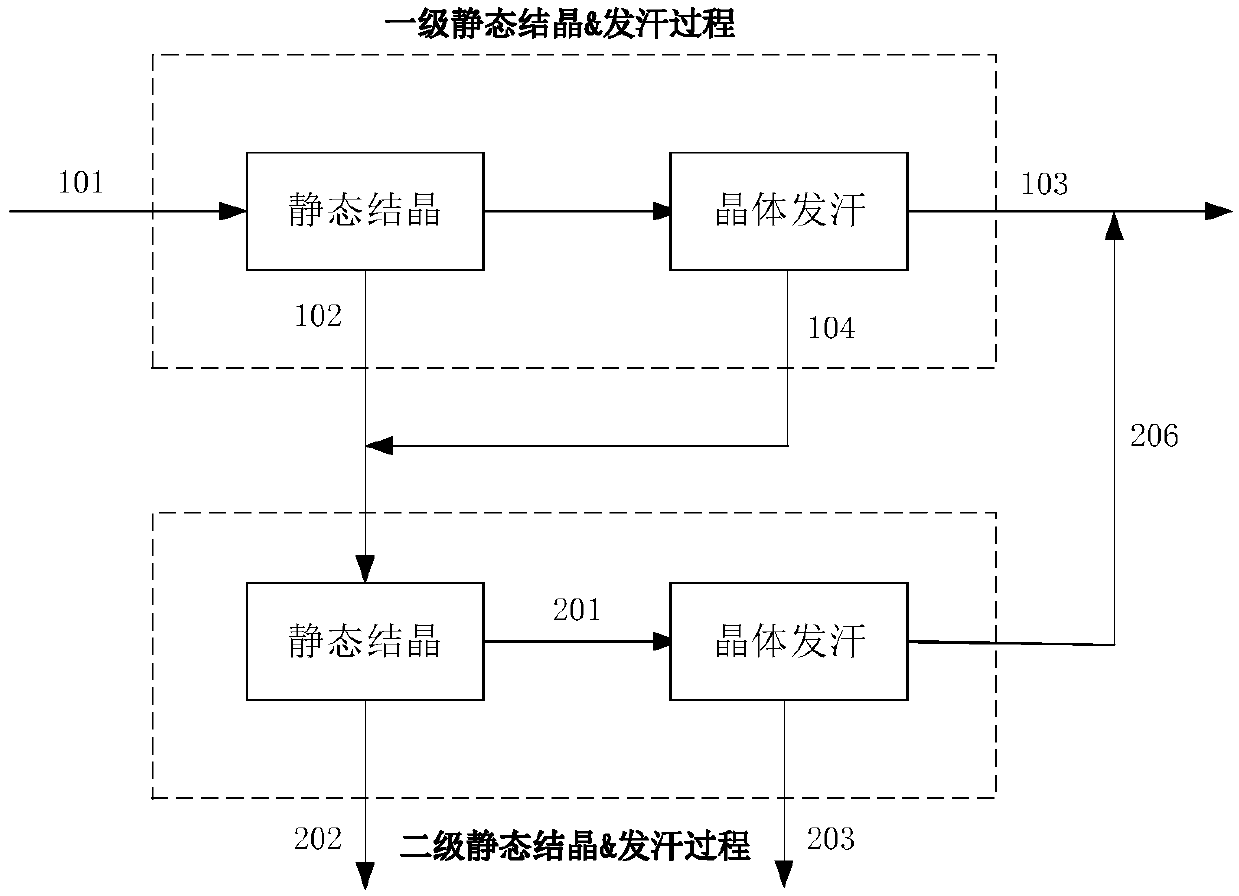

[0046] according to figure 2 Shown flow process adopts the raw material composition identical with embodiment 1, joins in such as Figure 4 The first-stage static crystallization & sweating are carried out in the static crystallizer shown, and the process parameters are the same as in Example 1, wherein the number of internal heat exchange tubes is 1, and the support on the heat exchange tubes is a single-layer stainless steel wire mesh, with a height of It is flush with the liquid level in the crystallizer, the outer jacket is kept at a constant temperature of 34°C, the seeding temperature is 34°C, the internal heat exchange tube is cooled by program, the cooling rate is 0.01°C / min, the crystallization end point temperature is 15°C, and the end point temperature is kept at a constant temperature for 60 minutes before stopping Crystallization, open the discharge port at the bottom of the static crystallizer, drain the mother liquor and start sweating of the crystals. At this ...

Embodiment 3

[0049] according to image 3 Shown flow process adopts the raw material composition identical with embodiment 1, joins in such as Figure 4The first-stage static crystallization & sweating are carried out in the static crystallizer shown, and the process parameters are the same as in Example 1, wherein the number of internal heat exchange tubes is 1, and the support on the heat exchange tubes is a single-layer stainless steel wire mesh, with a height of It is flush with the liquid level in the crystallizer, the outer jacket is kept at a constant temperature of 34°C, the seeding temperature is 34°C, the internal heat exchange tube is cooled by program, the cooling rate is 0.02°C / min, the crystallization end point temperature is 15°C, and the end point temperature is kept at a constant temperature for 60 minutes before stopping Crystallization, open the discharge port at the bottom of the static crystallizer, drain the mother liquor and start sweating of the crystals. At this ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com