Compound paint baking process for panel of exhibition cabinet

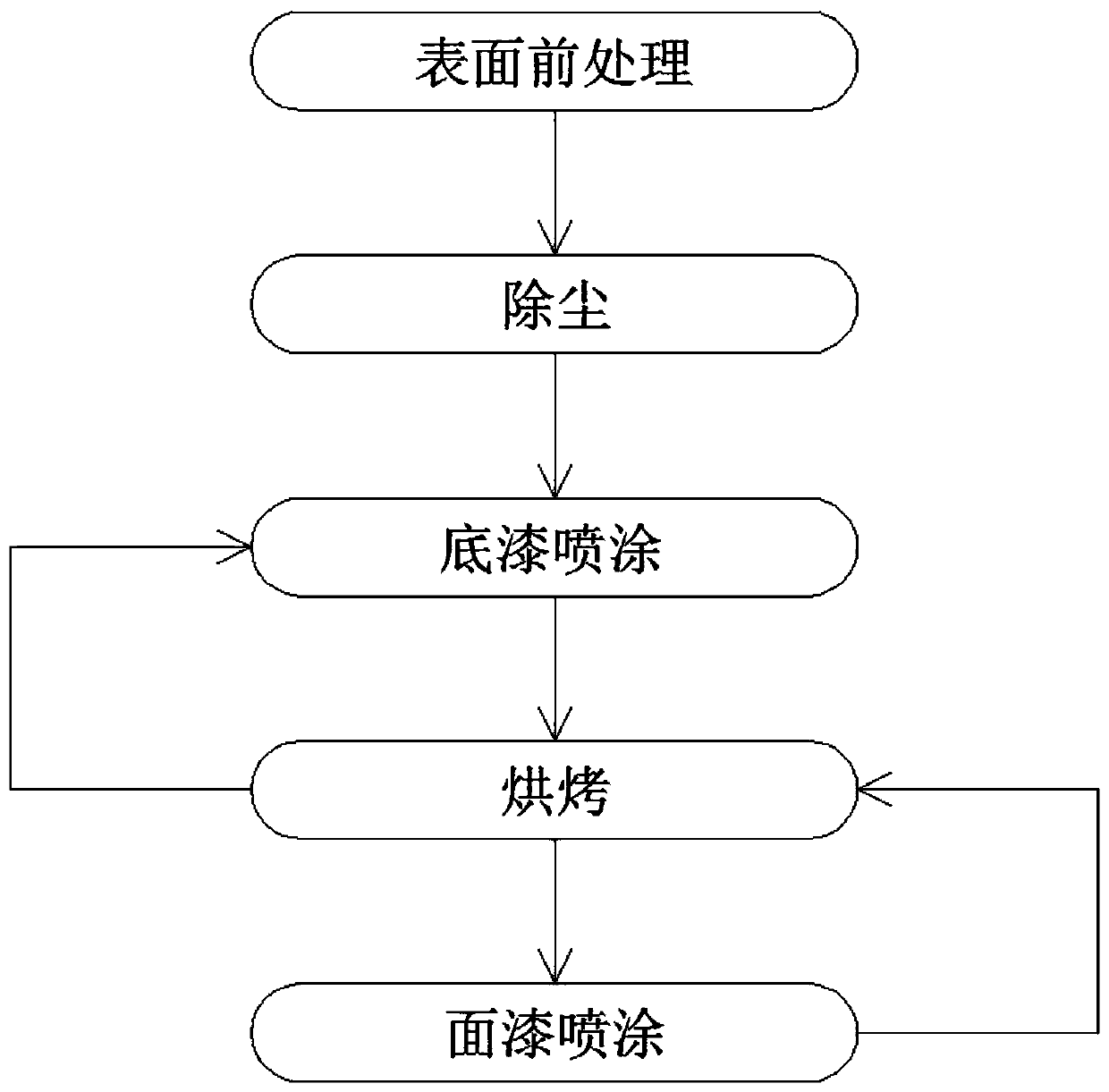

A panel and showcase technology, applied in the field of baking paint, can solve the problems of time-consuming and laborious, easy to miss, dust falling on the surface of the showcase panel, etc., to achieve the effect of convenient use, uniform painting, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

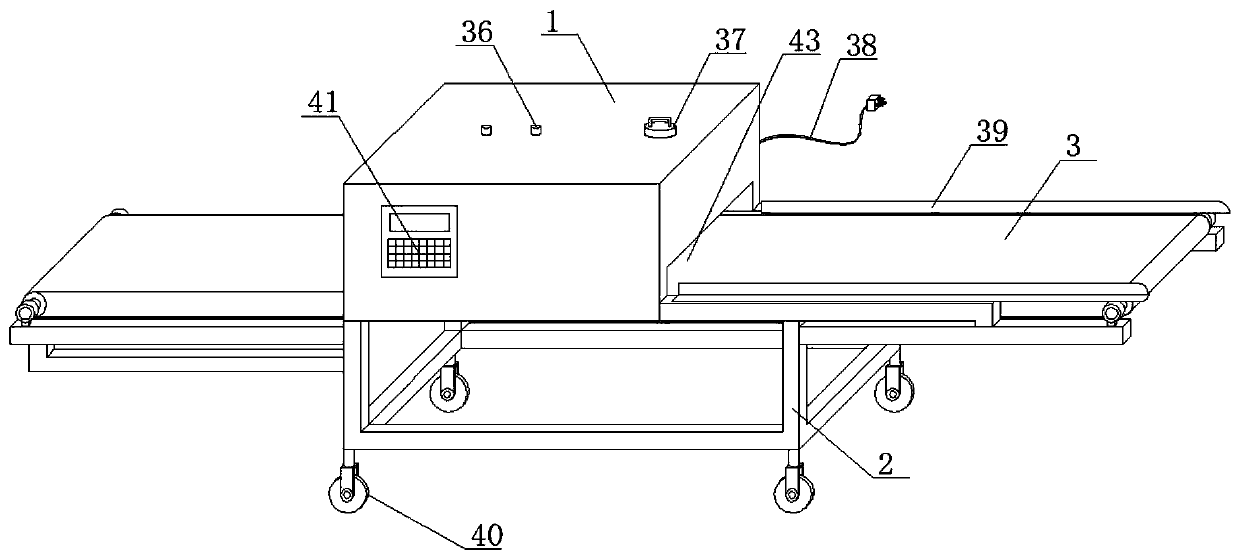

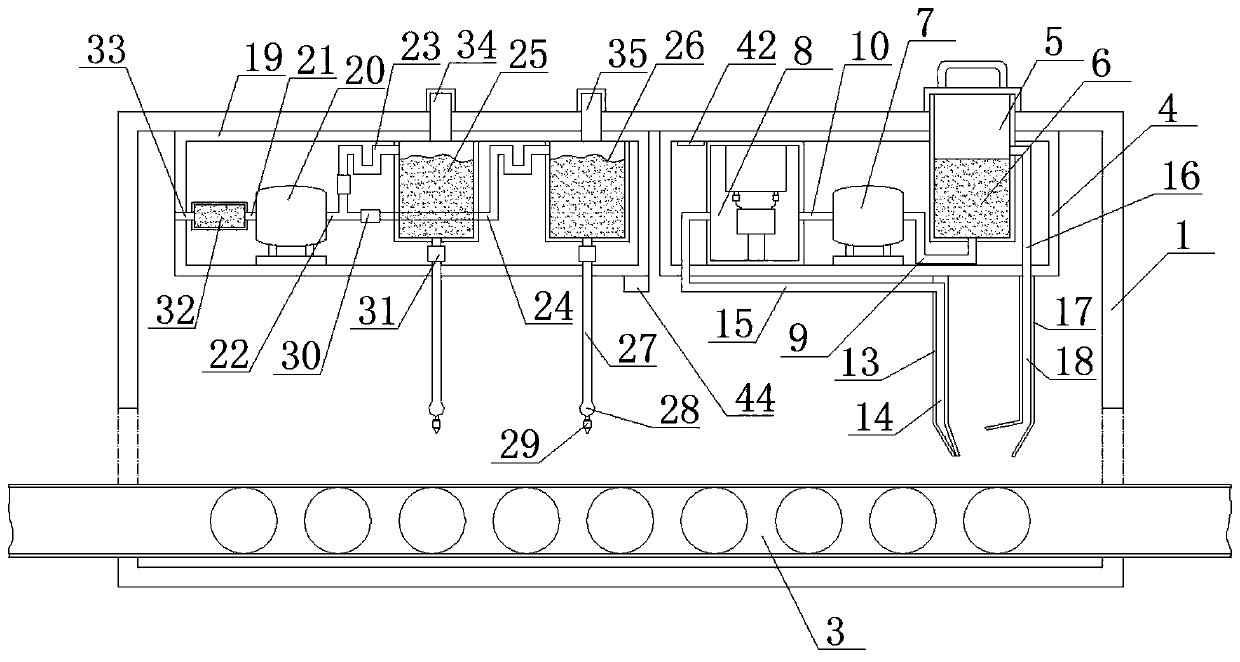

[0032] As a preferred embodiment of the present invention, rollers 40 are fixedly installed at corners of the bottom of the support frame 2 .

[0033] As a preferred embodiment of the present invention, the power cord 38 is respectively connected to the processor 42, the conveyor belt 3, the operation button 41, the infrared sensor 44, the high voltage generator 11, the ionization device 12, the dust removal air pump 7, the spray paint booster, etc. through the power supply circuit. The pressure pump 20, the electric valve one 30 and the electric valve two 31 are electrically connected, and the processor 42 is respectively connected with the conveyor belt 3, the operation button 41, the infrared sensor 44, the high voltage generator 11, the ionization device 12, the dust removal air pump 7, the spray paint booster The pressure pump 20, the electric valve one 30 and the electric valve two 31 are electrically connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com