Preparation and application of ultrathin two-dimensional layered composite photocatalytic materials

A composite photocatalytic, two-dimensional layered technology, applied in the field of photocatalytic materials, can solve the problems of complex preparation process, damage to tooth and bone development, etc., and achieve the effects of simple preparation process, multiple active sites, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

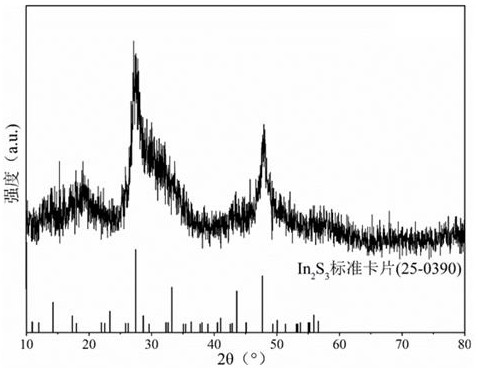

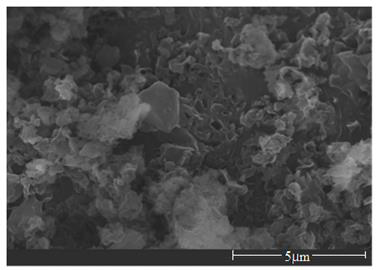

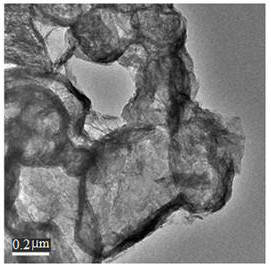

Embodiment 1

[0023] Weigh 5g of urea into a 25mL crucible, heat to 550°C in a muffle furnace at a heating rate of 5°C / min, keep it warm for 4 hours, cool naturally to 20°C, and then heat to 520°C at a heating rate of 2°C / min , keep warm for 2h, cool naturally at 25°C, grind into powder, and get g-C 3 N 4 nanosheets; 0.2 g of g-C 3 N 4 The nanosheets were dispersed into a three-necked flask filled with 100 mL of deionized water, then 1 mL of graphene oxide solution with a mass volume concentration of 2 mg / mL was added, and ultrasonically stirred for 20 min to make g-C 3 N 4 Mix the nanosheets and graphene oxide evenly, cool and reflux at 95°C, stir for 6 hours, and wash the solution by centrifugation after cooling to obtain g-C 3 N 4 / rGO complex; 0.2289g of In(NO 3 ) 3 ·5H 2 O, 0.3645g of cetyltrimethylammonium bromide and 0.135g of thioacetamide were added to a three-necked flask containing 100mL of deionized water, stirred ultrasonically for 20min, and then added 0.2g of g-C 3 N...

Embodiment 2

[0034] Weigh 20g of urea into a 100mL crucible, heat it to 535°C in a muffle furnace at a heating rate of 3.5°C / min, keep it warm for 3 hours, and cool it down to 25°C in natural cooling, then heat it to 550°C at a heating rate of 5°C / min , keep warm for 4h, cool naturally at 30°C, grind into powder, and get g-C 3 N 4 nanosheets; 1 g of g-C 3 N 4 The nanosheets were dispersed into a three-necked flask filled with 200 mL of deionized water, and then 5 mL of graphene oxide solution with a mass volume concentration of 2 mg / mL was added, and stirred ultrasonically for 30 min to make the g-C 3 N 4 Mix the nanosheets and graphene oxide evenly, cool and reflux at 90°C, stir for 4 hours, and wash the solution by centrifugation after cooling to obtain g-C 3 N 4 / rGO complex; 0.0457g of In(NO 3 ) 3 ·5H 2 O, 0.9113g of cetyltrimethylammonium bromide and 0.189g of thioacetamide were added to a three-necked flask containing 200mL of deionized water, stirred ultrasonically for 15min...

Embodiment 3

[0036] Weigh 12.5g of urea into a 65mL crucible, heat it to 520°C in a muffle furnace at a heating rate of 2°C / min, keep it warm for 2h, cool naturally to 30°C, and then heat it to 535°C at a heating rate of 3.5°C / min ℃, keep warm for 3h, cool naturally at 20℃, grind into powder, and get g-C 3 N 4 nanosheets; 0.6 g of g-C 3 N 4 The nanosheets were dispersed into a three-neck flask filled with 40 mL of deionized water, then 3 mL of graphene oxide solution with a mass volume concentration of 2 mg / mL was added, and ultrasonically stirred for 25 min to make the g-C 3 N 4 Mix the nanosheets and graphene oxide evenly, cool and reflux at 92.5°C, stir for 5 hours, and wash the solution by centrifugation after cooling to obtain g-C 3 N 4 / rGO complex; 0.3205g of In(NO 3 ) 3 ·5H 2 O. Add 1.4580g of cetyltrimethylammonium bromide and 0.027g of thioacetamide into a three-necked flask containing 150mL of deionized water, stir ultrasonically for 10min, and then add 0.15g of g-C 3 N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com