Automatic winding production process of integrally formed inductors

A production process and an integrated technology, applied in the field of inductance, can solve the problems of poor consistency of inductance coil winding, inconformity with the large-scale production of integrated molding inductance, and low production efficiency of inductance coil production process, and achieve the goal of improving assembly efficiency and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

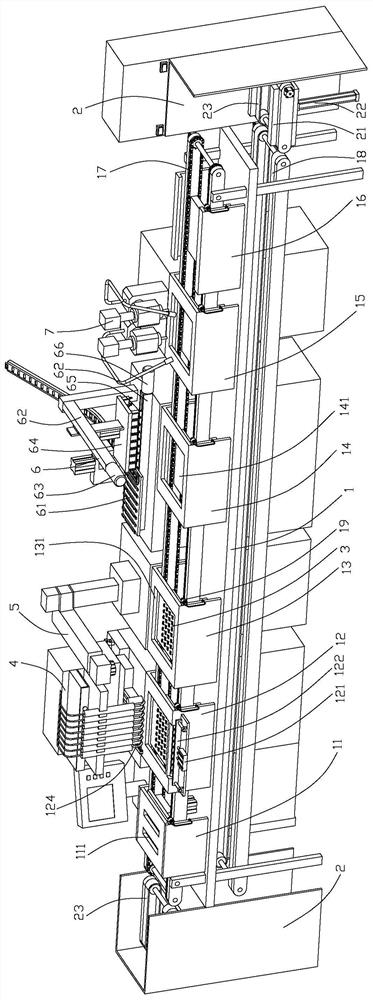

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

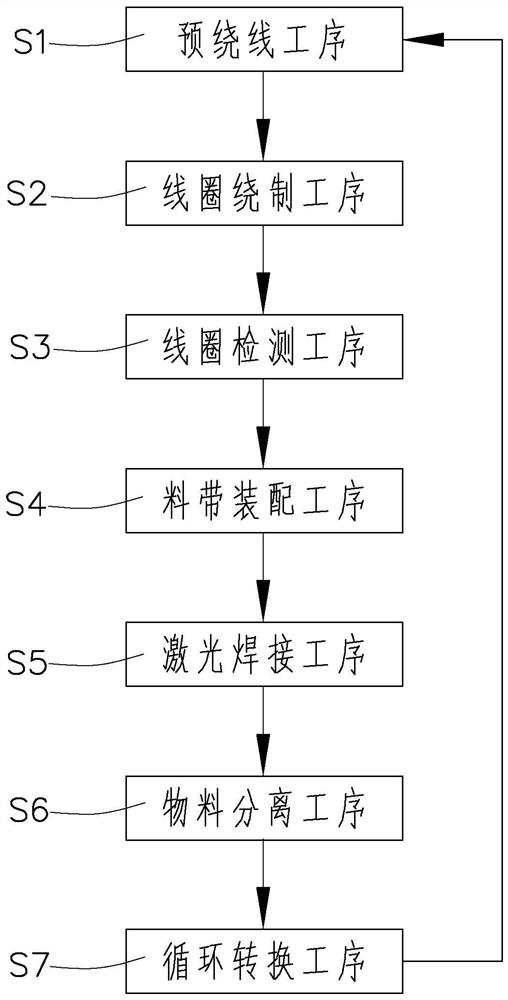

[0048] refer to figure 1 , figure 2 , which is an automatic winding production process for an integrally formed inductor disclosed in the present invention, is implemented in turn according to the following process steps:

[0049] S1, pre-winding process:

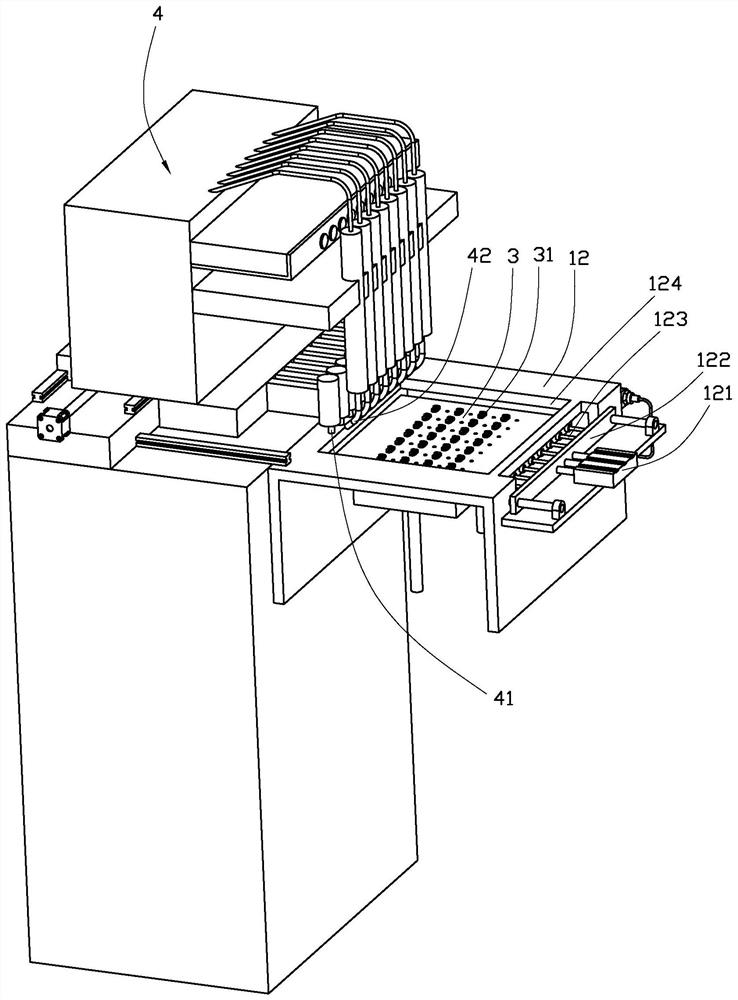

[0050] The coil fixture 3 moves forward along the transmission chain 17 installed on the upper part of the assembly line workbench 1 to the bottom of the pre-winding station 11, where a column of winding columns is located directly below the bar-shaped gap 111, and the pre-winding station As soon as the cylinder below 11 starts to work, the piston rod of cylinder one stretches out upwards and drives the top block to be placed on the lower end of the row of winding post groups, and at the same time pushes the upper end of each winding post 31 of the row of winding post groups to extend. Into the strip-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com