Automatic winding device for acetic acid cloth tape of automobile wire harness

A technology of automobile wiring harness and winding device, which is applied to electrical components, circuits, and conductor/cable insulation, etc., can solve problems such as the inability to apply automatic synchronous winding tape and release paper to stripping of automobile wiring harnesses, reducing production efficiency, and increasing equipment costs, etc. Achieve significant economic benefits, increase production speed, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

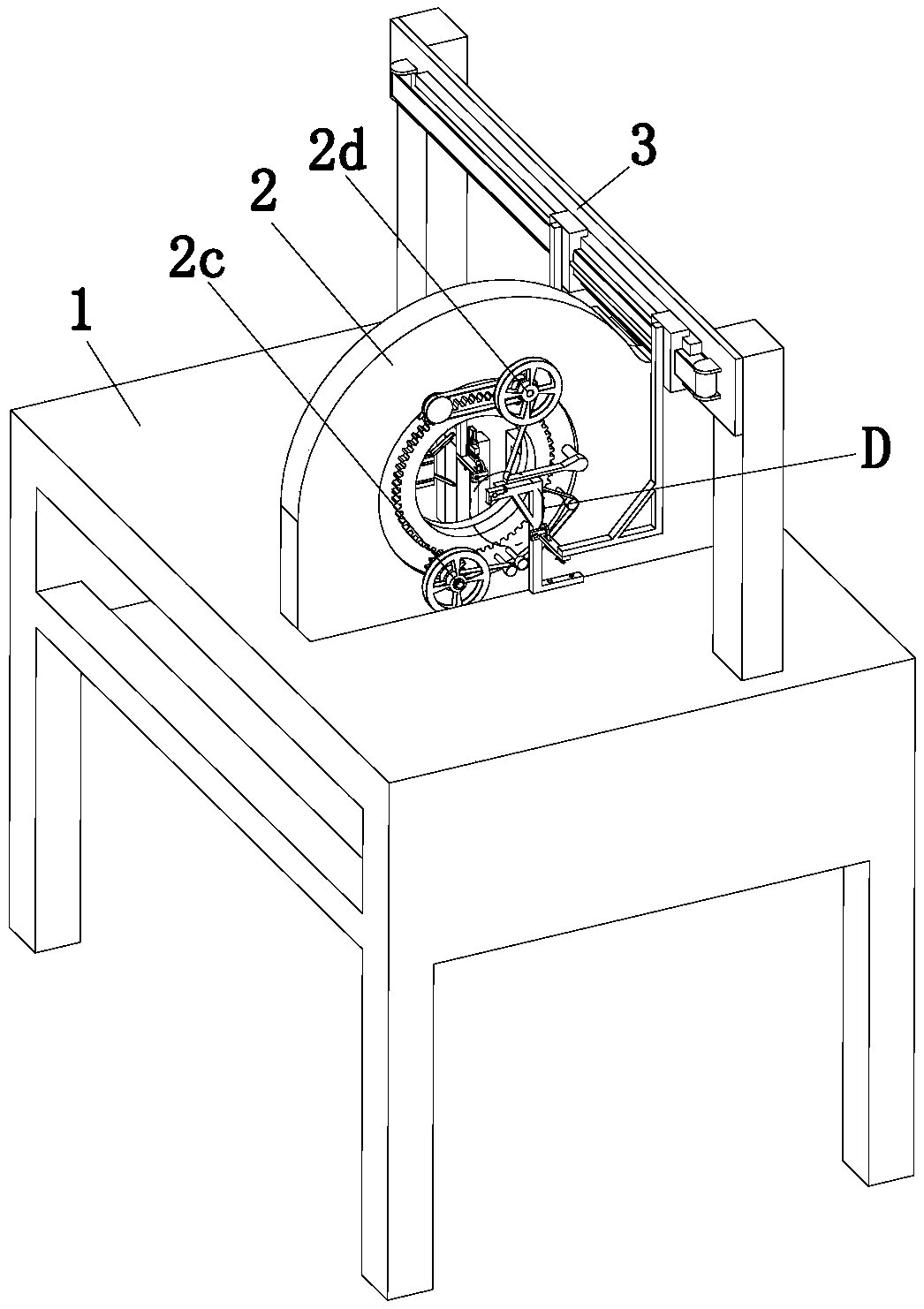

Image

Examples

Embodiment 1

[0047] The winding process of the automobile wiring harness acetate cloth tape automatic winding device described in embodiment 1 comprises the following steps:

[0048]In the first step, the worker passes one end of the automobile wiring harness through the circular groove and places it on the first traction assembly 3b, works through the traction cylinder 3b1 in the first traction assembly 3b, and is driven by the connecting block 3b3 and the connecting part 3b4 Make the two engaging blocks 3b5 engage, clamp one end of the automobile wire harness through the elastic block 5, and the traction cylinder 3b1 in the second traction assembly 3c works, so that the two engaging blocks 3b5 engage to form a circular groove to limit the automobile wire harness position, the worker pulls out one end of the tape and wraps it around one end of the car wiring harness;

[0049] In the second step, the rotating motor 2b1 works to drive the driving gear 2b2 to rotate, and the driving gear 2b2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com