Anti-emulsification precipitant for assisting extraction of a weak-polarity-non-polar target and application thereof

A non-polar solvent, non-polar technology, used in the field of precipitation purification agents, can solve the problems of low recovery rate, difficult separation, difficult to dissociate, etc., achieve strong purification of impurities, overcome emulsification, and high extraction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

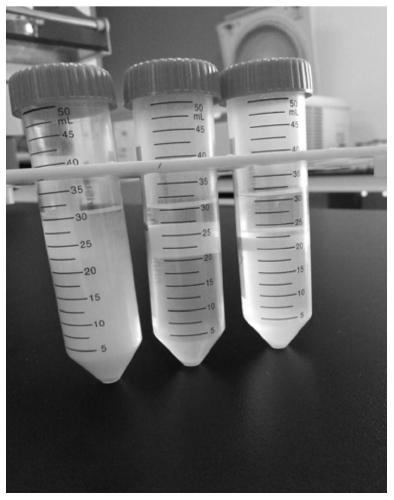

Image

Examples

specific Embodiment 1

[0024] An anti-emulsification precipitant for assisting the extraction of weakly polar-nonpolar target substances. The anti-emulsification precipitant is mainly composed of the following raw materials and their proportions: 500 mL of ammonium acetate buffer solution, 2 g of polyethylene glycol, and lower alcohol 200 mL, 500 mL of acetonitrile and 20 mL of n-octanol, and adjust the pH to 4.8 with formic acid. The lower alcohol is methanol or ethanol, and the concentration of ammonium acetate buffer is 1 mol / L.

specific Embodiment 2

[0026] The use method of the anti-emulsification precipitating agent that assists weak polarity-nonpolar target substance extraction in specific embodiment one, comprises the following steps:

[0027] (1) For water-containing samples to be tested (such as muscle, viscera, fruits, vegetables, etc.), add an equal volume of ethanol to the sample to be tested; for dry samples without water (such as infant formula milk powder, starch, animal feed, etc.) , add water equal to the weight of the dry sample, fully vortex and mix to obtain the sample to be tested, and add ethanol equal to the volume of the sample to be tested;

[0028] (2) Add 9 times the volume of anti-emulsifying precipitant and 5 times the volume of non-polar solvent of the sample to be tested, homogenize at a high speed of 10000 rpm for 2 minutes, then centrifuge at 4000 rpm for 10 minutes, and separate into two layers of supernatant, Collect the supernatant, then repeat the extraction with non-polar solvent 5 times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com