A method for synthesizing Y-type molecular sieves containing mesopores and high crystallinity

A technology of high crystallinity and molecular sieve, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of limited improvement of acidity and hydrothermal stability, failure to meet the requirements of FCC, etc. Achieve the effects of obvious mesopore characteristics, simple preparation method and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

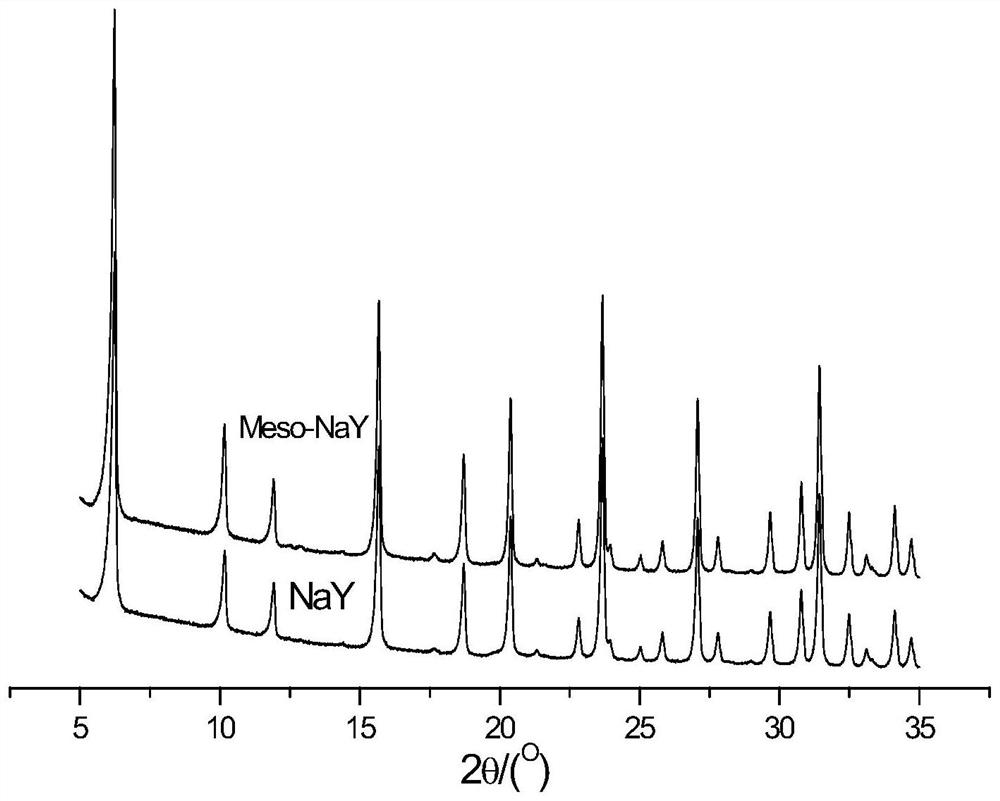

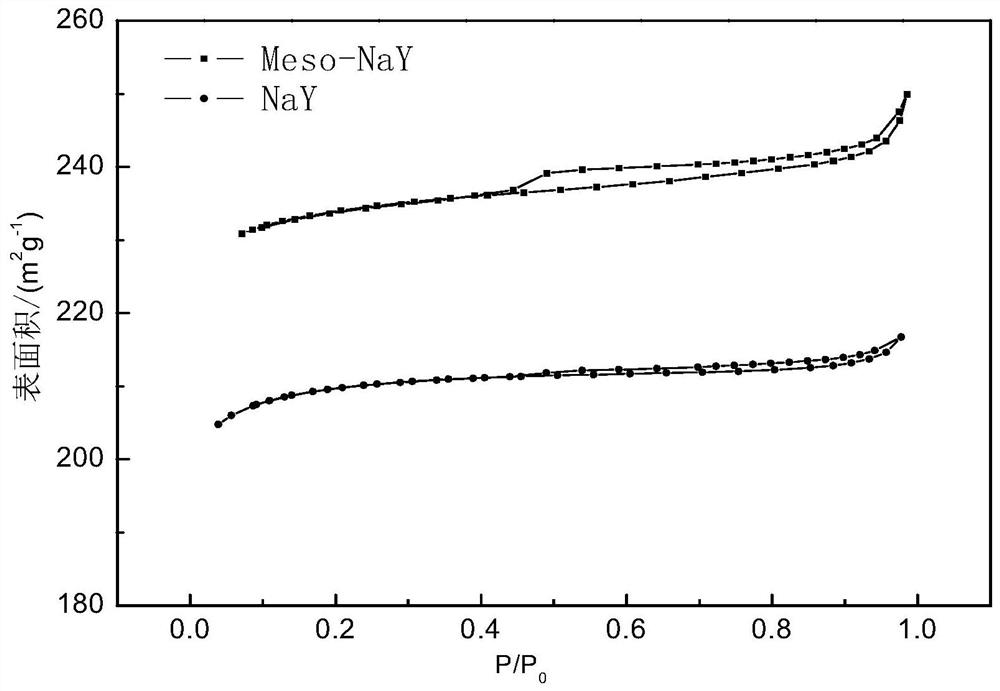

Image

Examples

preparation example Construction

[0018] The method of high crystallinity containing mesoporous synthetic Y type zeolite, wherein the preparation process characterized in that it comprises:

[0019] (1) according to Al 2 O 3 : (1 ~ 35) SiO 2 : (10 ~ 35) Na 2 O: (180 ~ 400) H 2 O molar ratio of the silicon source, an aluminum source and water are mixed, and then allowed to stand for aging for 0.5 ~ 60h crystallization directing agent to give at 0 ~ 80 ℃;

[0020] (2) Add an alkaline source and water in a cationic starch template for 2,3-epoxypropyltrimethylammonium chloride modification of 0.01% to 10%, and the cation starch template, an alkali source. And the mass ratio of water is (0.1 ~ 5): (0.1 ~ 3): (1 to 100), then hydrolyzed by water at 30 to 150 ° C;

[0021] (3) The Al 2 O 3 : (1 ~ 20) SiO 2 : (1 ~ 10) Na 2 O: (120 ~ 300) H 2 Molar ratio of O to silicon source in step (2) hydrolyzing the resulting product of step (1) feeding sequence resulting crystallization directing agent, an aluminum source and a base ...

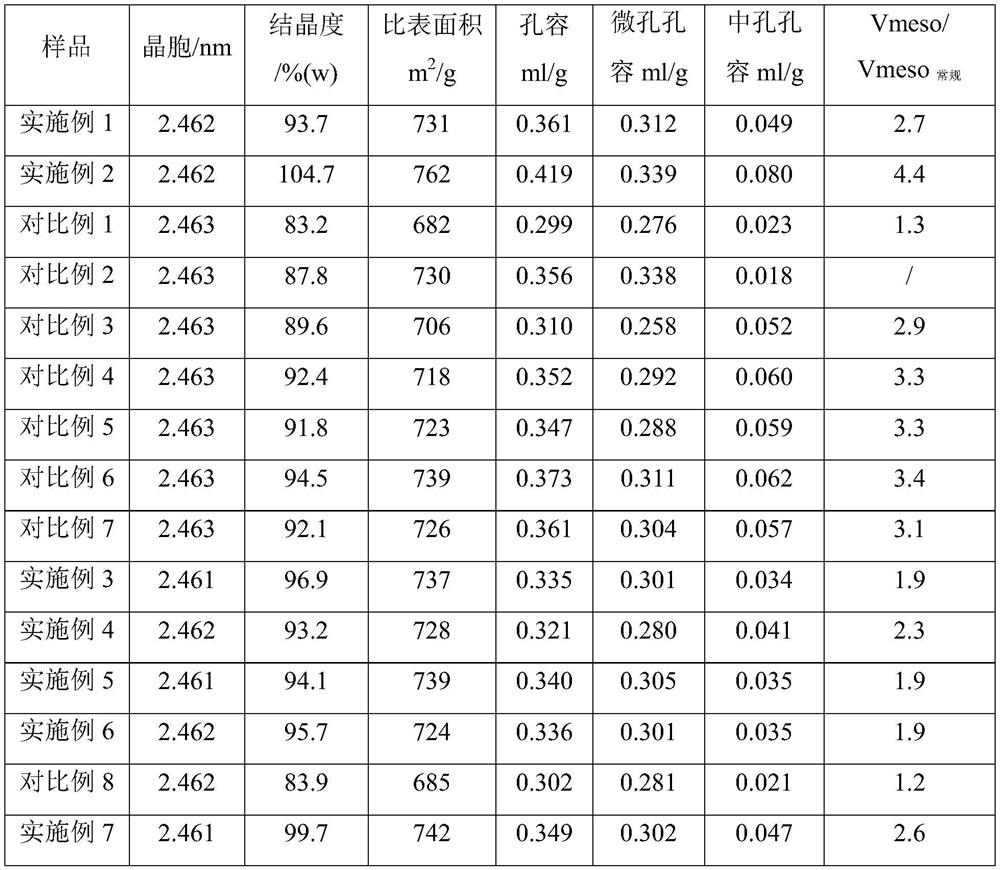

Embodiment 1

[0039] According to Al 2 O 3 : 15sio 2 : 16.5NA 2 O: 320h 2 The molar ratio of O. 30 ml of water glass (modulus 3.3) was added to 20.8 ml of sodium aluminate, stirred and dissolved, and then the aging temperature was 30 ° C, the aging time was 20 h, and the crystallization guide agent was obtained.

[0040] 1 g of YZA-1 cationic starch (2,3-epoxypropyltrimethylammonium chloride substitution 1%) was placed in 60 g of water, then 0.5 g of NaOH, stirred well, warm to 40 ° C, constant temperature stirred for 1h hydrolysis deal with.

[0041] Then, after the above hydrolysis treatment, YZA-1 cationic starch (substitute 1%) was added to 50 ml of water glass (modulus 3.3), stirred for 0.5 h, and then the above 12g guiding agent was added, stirred for 1 h, then add 30 ml of aluminum sulfate And 10 ml of sodium aluminate, after completion of the mixture for 1 h, finally put the mixture into a stainless steel crystalline altal, after sealed crystallization at 90 ° C for 30 h, filtered, wash...

Embodiment 2

[0044] According to Al 2 O 3 : 15sio 2 : 16.5NA 2 O: 320h 2 The molar ratio of O, 30 ml of water glass (modulus 3.3) was added to 20.8 ml of sodium aluminate, stirred and dissolved, and then the aging temperature was 45 ° C, the aging time was 5 h, and the crystallization guiding agent was obtained.

[0045] 2 Gyza-2 cationic starch (2,3-epoxypropyltrimethylammonium chloride substitution was 0.5%) 60 g of water, and 1 g NaOH was added, stirred well, warmed to 60 ° C, and the temperature was stirred for 1 h hydrolysis treatment.

[0046] The above hydrolysis treatment was added to 65 ml of water glass (analog number 3.3) after the above hydrolysis treatment, and stirred for 0.5 h, and then the above addition was added to the above-mentioned 18 g of the guide agent, stirred for 1 h, then add 40 ml of aluminum sulfate And 18 ml of sodium aluminate, then continued to stir for 1 h after completion, finally put the mixture in a stainless steel crystalline altal, after sealed crystalliza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com