A kind of active mesoporous silica-alumina catalytic material

A catalytic material, mesoporous silicon-alumina technology, applied in catalytic cracking, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem of low impurity content, uneven distribution of silicon and aluminum, expensive and stable organic silicon prices issues of sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example illustrates the preparation of the active mesoporous silica-alumina catalytic material provided by the present invention.

[0027] Take Al 2 (SO 4 ) 3 Solution (concentration 90gAl 2 o 3 / L) and ammonia (mass fraction 25%) are reaction raw materials. Using the method of co-flow gelation, under vigorous stirring, the Al 2 (SO 4 ) 3 Solution and ammoniacal liquor are mixed into gel, and the temperature of controlling gelation is 40 ℃, and the pH value of gelation system remains on 9.0, simultaneously the water glass solution of metering (concentration 100gSiO 2 / L) mixed with the above-mentioned colloidal slurry in parallel flow to realize the online addition of silicon source. After collecting a certain amount of mixed slurry, raise the temperature to 70°C and age for 2 hours; Base: Ammonium Salt: H 2 The weight ratio of O=1:0.5:15 was exchanged at 60°C for 0.5 hours, filtered and washed with water, and the ammonium exchange was repeated once. After ...

Embodiment 2

[0034] This example illustrates the preparation of the active mesoporous silica-alumina catalytic material provided by the present invention.

[0035] Take Al 2 (SO 4 ) 3 The solution and ammonia water are used as the reaction raw materials, and the Al 2 (SO 4 ) 3 The solution and ammonia water are mixed to form a gel, the gelation temperature is controlled at 30°C, the pH value of the gelation system is maintained at 10.0, and the metered water glass solution and the above-mentioned gelation slurry are mixed in parallel to realize the on-line silicon source Add, after collecting a certain amount of mixed slurry, raise the temperature to 60°C and age for 2 hours; after filtering, the obtained solid precipitate is calculated on a dry basis of the precipitate: ammonium salt: H 2 The weight ratio of O=1:1:15 was exchanged at 70° C. for 0.5 hours, filtered and washed with water, and the active mesoporous silica-alumina catalytic material provided by the present invention was ...

Embodiment 3

[0042] This example illustrates the preparation of the active mesoporous silica-alumina catalytic material provided by the present invention.

[0043] Take Al 2 (SO 4 ) 3 solution and NaAlO 2 Solution (concentration 190gAl 2 o 3 / L) is the reaction raw material, at room temperature co-flow into gel and control the pH value of the gel-forming process to remain at 10.5, and simultaneously mix the water glass solution and the gel-forming slurry in proportion to realize the on-line addition of silicon source, and then Warm up the collected slurry to 60°C and age for 4 hours; filter the resulting solid precipitate on a dry basis: ammonium salt: H 2 The weight ratio of O=1:0.8:12 was exchanged at 55° C. for 1 hour, filtered and washed with water, and the active mesoporous silica-alumina catalyst material provided by the present invention was obtained, denoted as AM-3.

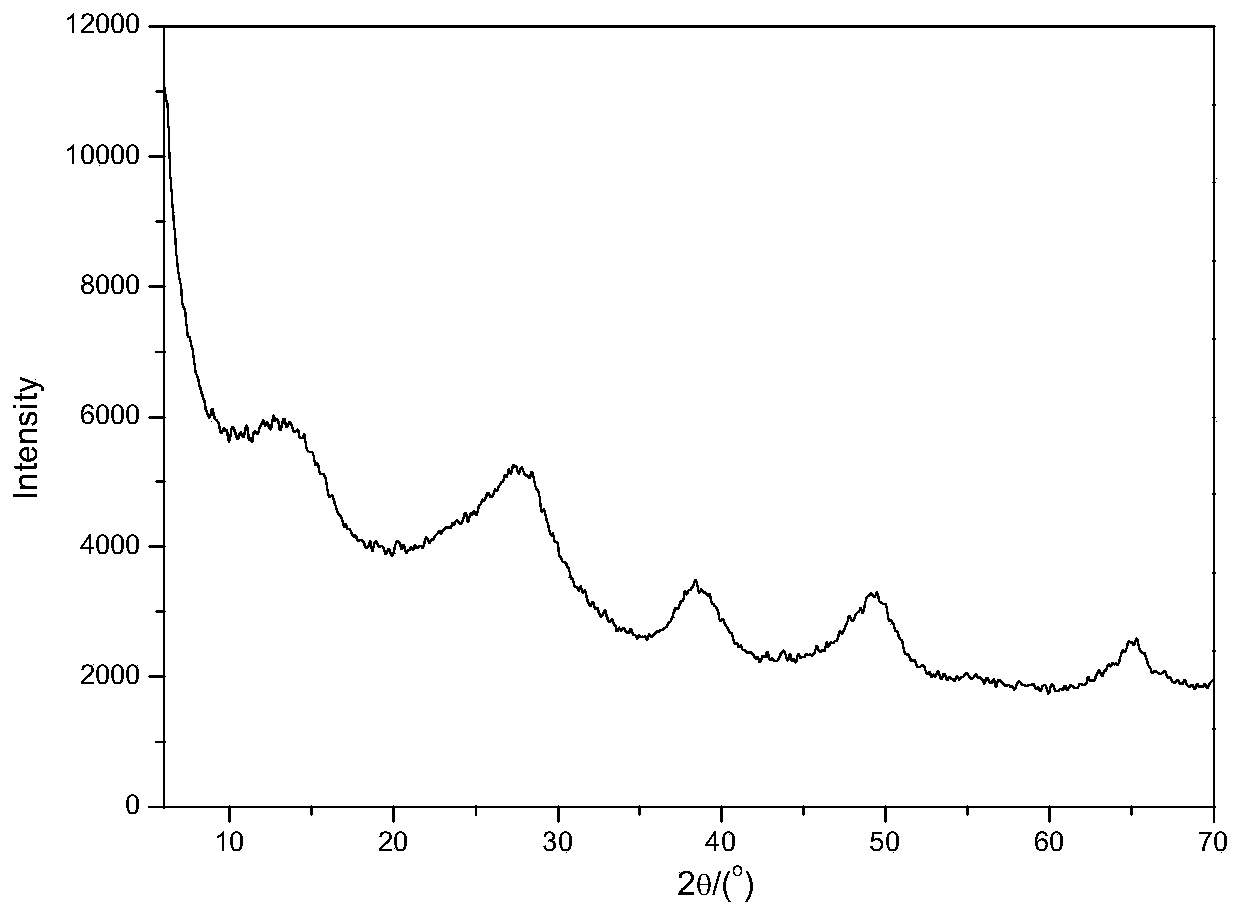

[0044] AM-3 has a pseudo-boehmite structure, and its X-ray diffraction spectrum is as shown in the accompany...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com