Method for leaching Carlin type gold ore through alkaline thiourea

A carlin type, gold mine technology, applied in the field of hydrometallurgy, can solve the problems of complex process and increased cost, and achieve the effect of simple process flow, low pollution, and eliminating the need for pretreatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

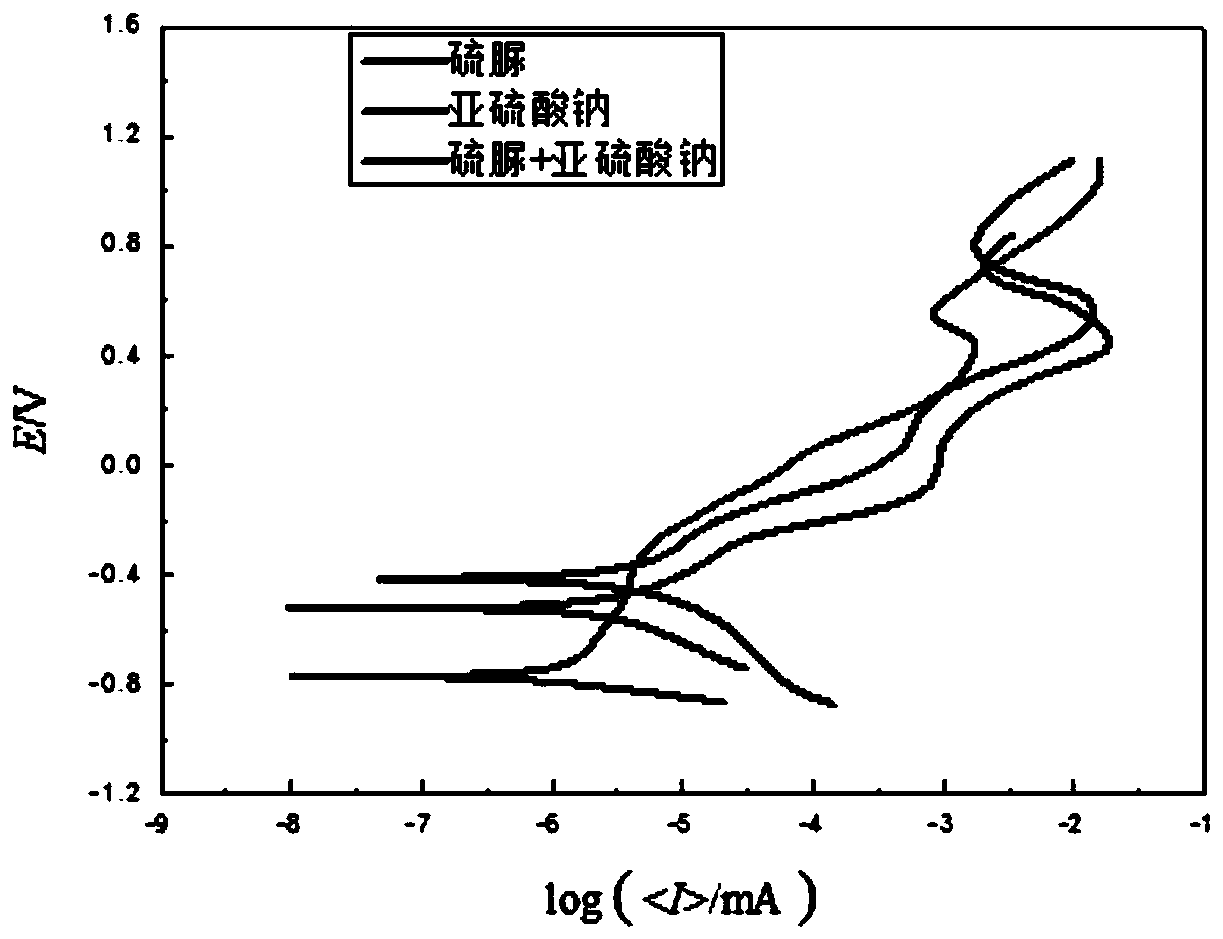

[0031] Effect of thiourea concentration on gold leaching:

[0032] Take 50g of Carlin-type gold ore ground to below 200 mesh as a group, a total of 5 groups, add clean glass containers, numbered 1, 2, 3, 4, 5 respectively, add 500 ml of distilled water to make slurry, so that the liquid-solid ratio is 10:1, sequentially add sodium sulfite, potassium persulfate, thiourea, sodium hydroxide, control the concentration of sodium sulfite to 0.1mol / L, the concentration of potassium persulfate to 0.05mol / L, and the concentration of thiourea to 0.01mol / L and 0.05mol / L respectively L, 0.10mol / L, 0.15mol / L, 0.20mol / L, pH=13, stirring and leaching at 25°C for 4 hours, the gold ore leaching rates were 39.6%, 64.2%, 62.7%, 62.3%, 63.1 %.

Embodiment 2

[0034] Effect of sodium sulfite concentration on gold leaching:

[0035] Take 50g of Carlin-type gold ore ground to below 200 mesh as a group, a total of 5 groups, add clean glass containers, numbered 1, 2, 3, 4, 5 respectively, add 500 ml of distilled water to make slurry, so that the liquid-solid ratio is 10:1, add sodium sulfite, potassium persulfate, thiourea, sodium hydroxide successively, control the concentration of sodium sulfite to be 0.05mol / L, 0.1mol / L, 0.15mol / L, 0.20mol / L, 0.25mol / L respectively, over Potassium sulfate concentration is 0.05mol / L, thiourea concentration is 0.10mol / L, pH=13, stirring and leaching at 25°C for 4 hours, the gold ore leaching rates are 37.2%, 66.1%, 68.6%, 67.5%, 64.1%.

Embodiment 3

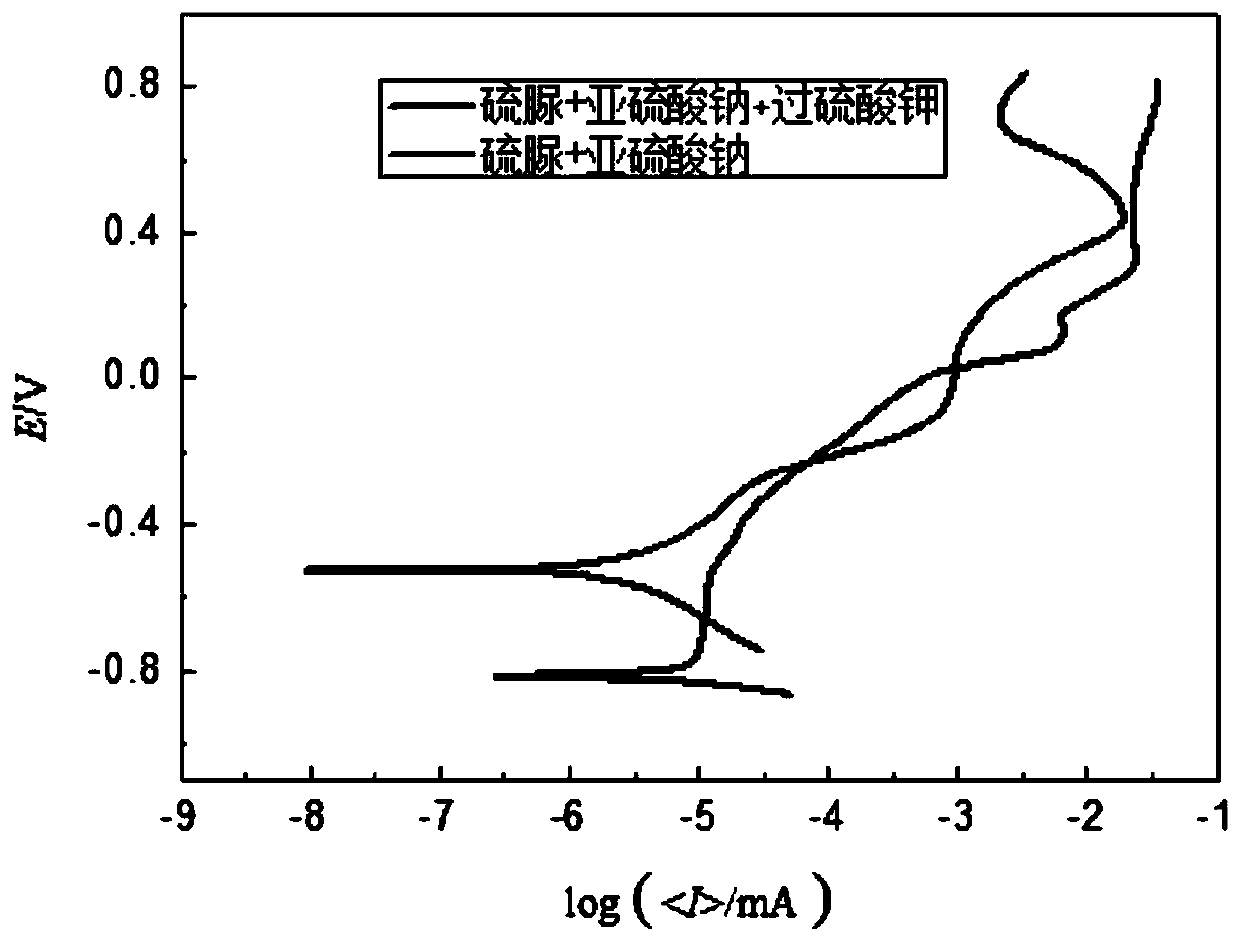

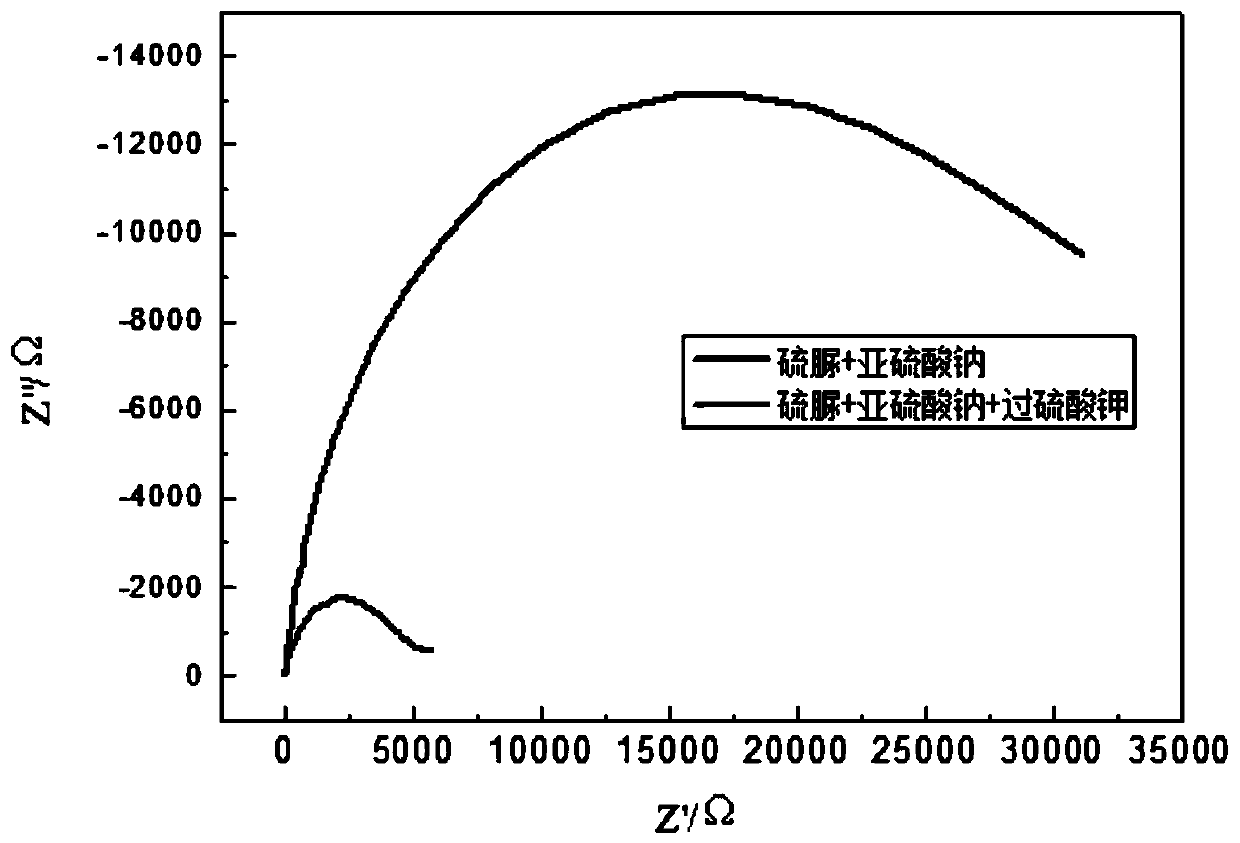

[0037] Effect of potassium persulfate concentration on gold leaching:

[0038] Take 50g of Carlin-type gold ore ground to below 200 mesh as a group, a total of 5 groups, add clean glass containers, numbered 1, 2, 3, 4, 5 respectively, add 500 ml of distilled water to make slurry, so that the liquid-solid ratio is 10:1, add sodium sulfite, potassium persulfate, thiourea, and sodium hydroxide in sequence, control the concentration of sodium sulfite to 0.15mol / L, and the concentration of potassium persulfate to 0.01mol / L, 0.03mol / L, 0.05mol / L, and 0.07mol respectively / L, 0.1mol / L, thiourea concentration 0.10mol / L, pH=13, stirred and leached at 25°C for 4 hours, the gold ore leaching rates were 56.2%, 65.4%, 69.2%, 72.5%, 71.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com