Method for preparing controllable photoluminescence carbon dots by changing temperature

A technology of photoluminescence and temperature change, which is applied in the direction of luminescent materials, chemical instruments and methods, nano-carbon, etc., can solve the problem of difficult separation of carbon dot mixture, achieve good photobleaching resistance and stability, easy operation process, The effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

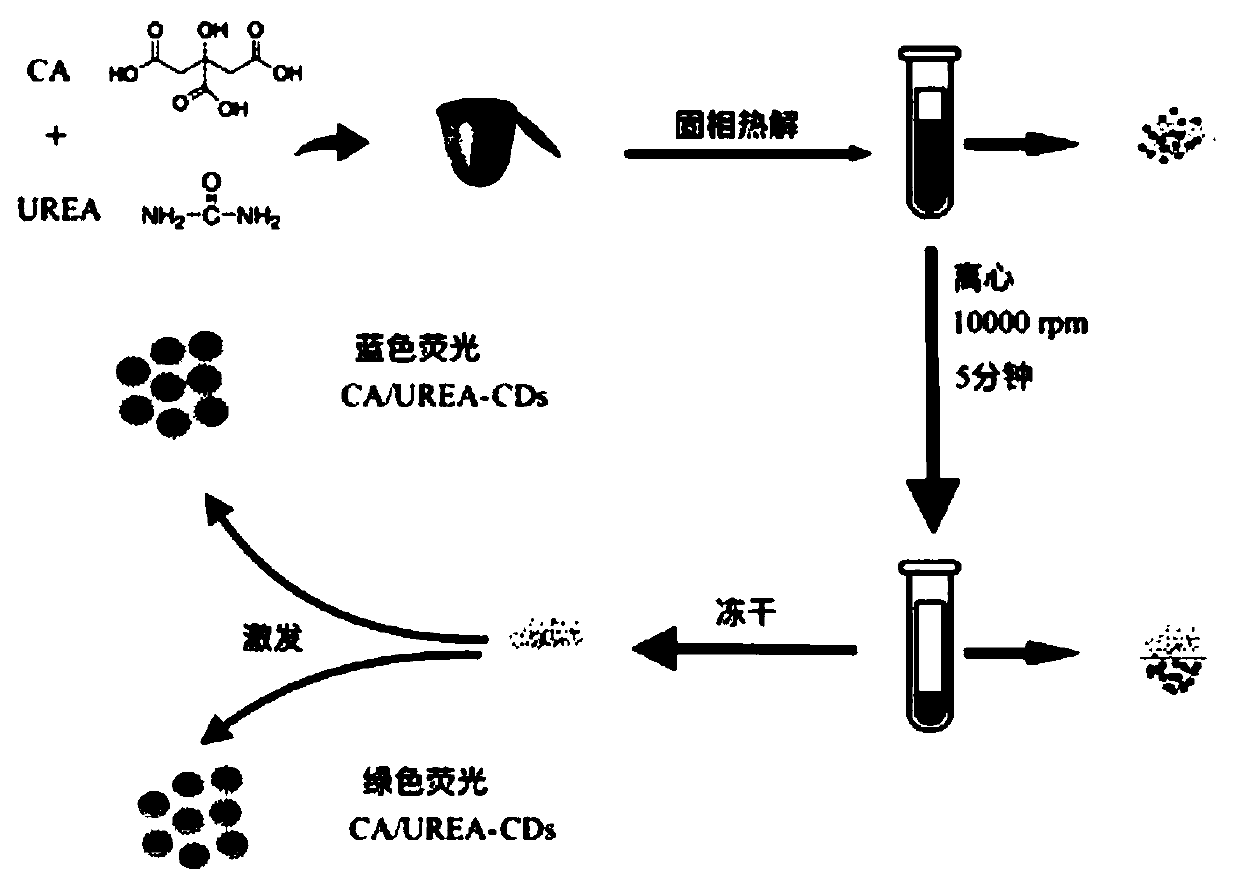

Embodiment 1

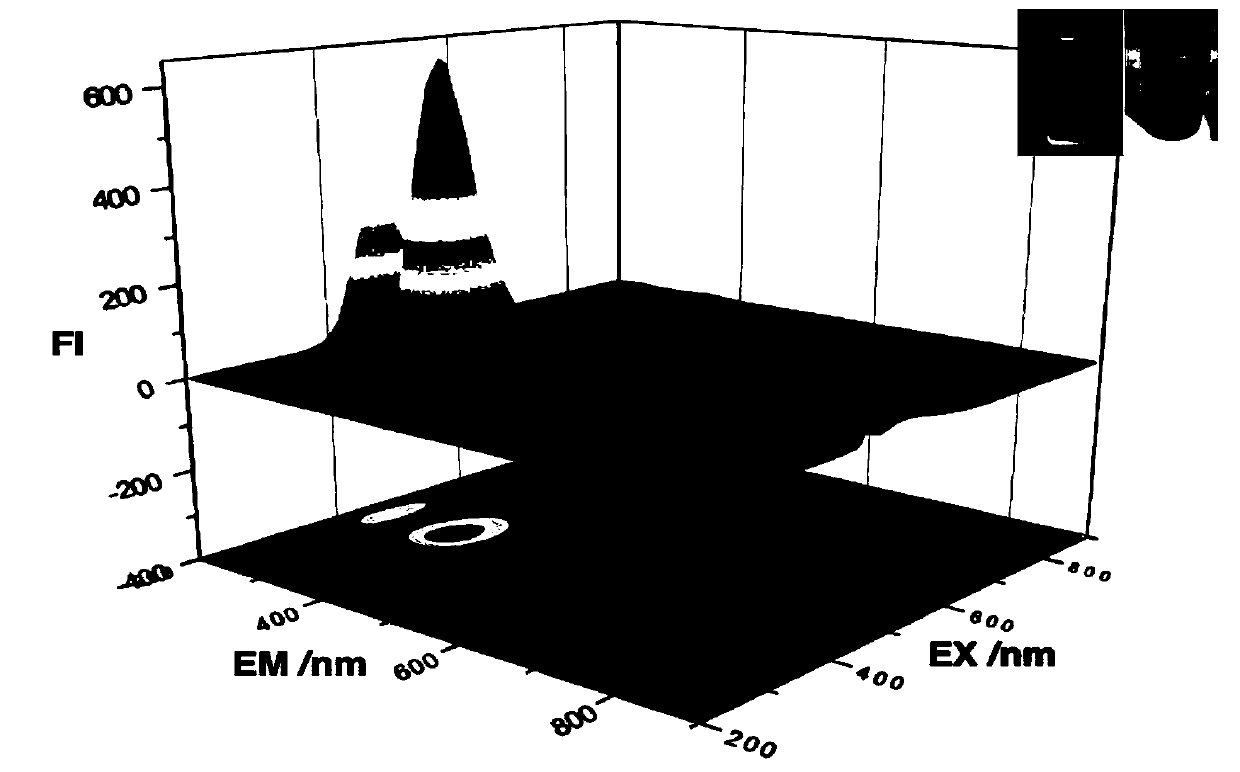

[0029] In order to study the method for preparing blue fluorescent carbon dots in the present invention, select citric acid monohydrate as the carbon source, urea as a nitrogen dopant, weigh 1 g of citric acid monohydrate solid, 2 g of urea, and fully mix them in a nickel crucible , placed in an oven at 150°C for 2 h to obtain a crude product of carbon dots. Cool the synthesized carbon dots (CA-N-CDs) slightly, add 10ml of deionized water to dissolve, and centrifuge at a high speed of 10000r / min for 10min after the synthesized product is fully dissolved, and take the supernatant ; The centrifuged carbon dots (CA-N-CDs) supernatant solution is filtered and purified through a 0.22 micron microporous membrane to obtain a carbon dot solution.

[0030] The above-mentioned purified sample solution is diluted to an ultraviolet absorbance lower than 0.05, and the fluorescence intensity of the solution is detected to obtain the fluorescence spectrum of the carbon dot solution. From thi...

Embodiment 2

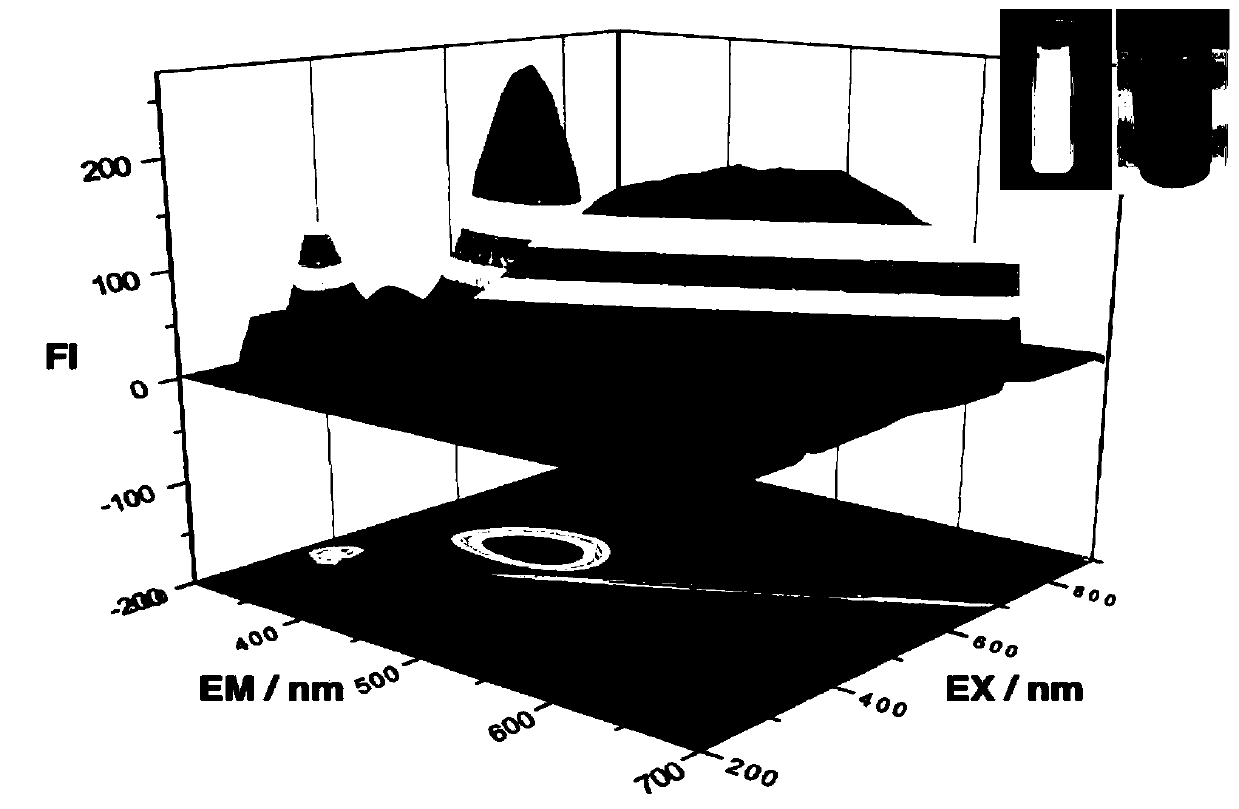

[0034] Study the method for preparing green fluorescent carbon dots in the present invention, modify the "calcination in an oven at 150°C for 2 hours" in Example 1 to "calcination in an oven at 180°C for 2 hours", and the rest are the same as in Example 1. A solution of carbon dots is obtained.

[0035] The above-mentioned purified sample solution is diluted to an ultraviolet absorbance lower than 0.05, and the fluorescence intensity of the solution is detected to obtain the fluorescence spectrum of the carbon dot solution. It can be seen that the prepared green carbon dot solution has an emission peak at 530nm in this spectrum (using In the ultraviolet absorption results, the maximum absorption peak is excited at 410nm), and has a strong fluorescence intensity. Observing the optical properties of carbon dots under the irradiation of ultraviolet light with the naked eye, you can see that they emit bright green light.

[0036] The purified product solution was lyophilized into...

Embodiment 3

[0039]In order to study the method for preparing blue fluorescent carbon dots in the present invention, select citric acid monohydrate as the carbon source, urea as a nitrogen dopant, weigh 1 g of citric acid monohydrate solid, 2 g of urea, and fully mix them in a nickel crucible , placed in an oven at 180°C for 0.2h to obtain a crude product of carbon dots. Cool the synthesized carbon dots (CA-N-CDs) slightly, add 10ml of deionized water to dissolve, and centrifuge at a high speed of 10000r / min for 10min after the synthesized product is fully dissolved, and take the supernatant ; The centrifuged carbon dots (CA-N-CDs) supernatant solution is filtered and purified through a 0.22 micron microporous membrane to obtain a carbon dot solution. The above-mentioned purified sample solution is diluted to an ultraviolet absorbance lower than 0.05, and the fluorescence intensity of the solution is detected to obtain the fluorescence spectrum of the carbon dot solution. It can be seen th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com