Preparation and detection method of high-purity high-melting-point sodium pantothenate

A detection method, the technology of sodium pantothenate, which is applied in the field of preparation and detection of high-purity and high-melting-point sodium pantothenate, can solve the problems of residual raw materials, low melting point, unstable purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

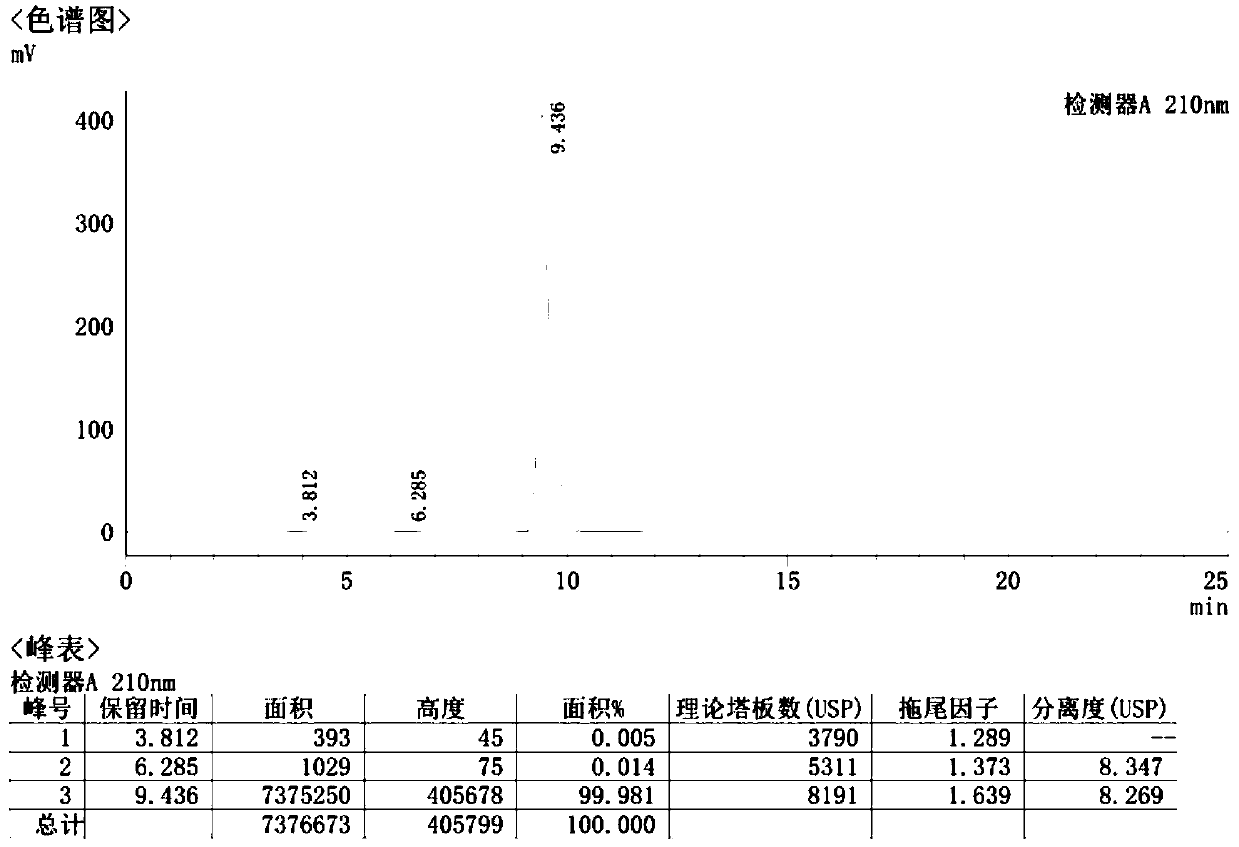

Embodiment 1

[0042] Take calcium pantothenate (50.0 g, 104.92 mmol) and dissolve it in 100 mL of purified water. Sodium carbonate (12.34g, 116.41mmol) was dissolved in 40mL of purified water. At 25°C, add the sodium carbonate aqueous solution dropwise to the calcium pantothenate aqueous solution, and after 20 minutes, the dropwise addition is completed, and then stir at the same temperature for 30 minutes. Filter and wash the filter cake with 10 mL of purified water. The filtrate was collected and tested with a pH meter. The pH value of the filtrate was between 9.0 and 10.0, and concentrated under reduced pressure at 75° C. (vacuum degree 0.090 MPa) until the moisture content of the oil was about 18%.

[0043] Add 100mL absolute ethanol to the oily substance and dissolve at 60°C. Then add 0.50 g (1%, m / m) of sodium pantothenate seed crystals, stir and disperse evenly, and stir and crystallize at 25° C. for 2 h. After more white particles were precipitated, 90 mL of acetonitrile was adde...

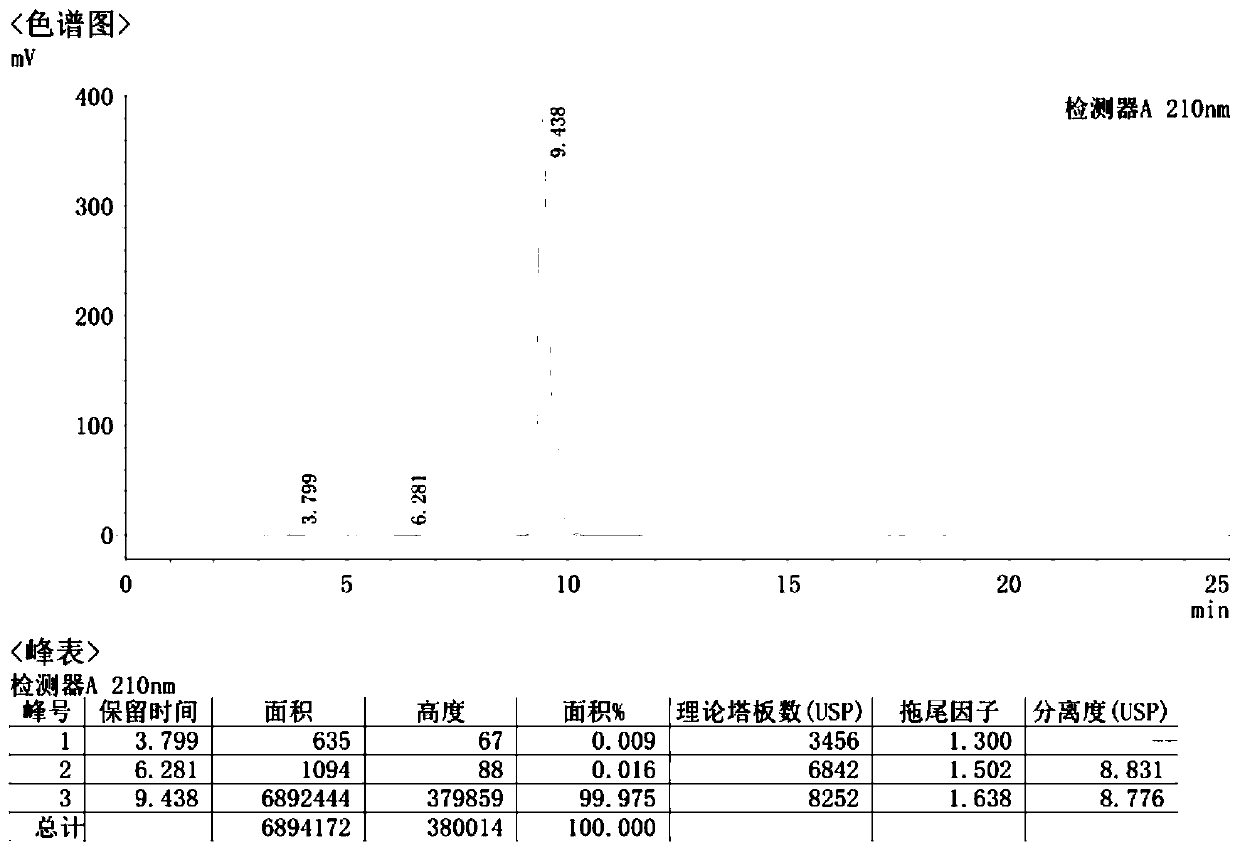

Embodiment 2

[0048] Take calcium pantothenate (50.20g, 105.34mmol) and dissolve it in 100mL of purified water. Sodium carbonate (12.34g, 116.41mmol) was dissolved in 40mL of purified water. Add the sodium carbonate aqueous solution dropwise to the calcium pantothenate aqueous solution at 28°C. After 30 minutes, the dropwise addition is completed, and then stir at the same temperature for 40 minutes. Filter and wash the filter cake with 10 mL of purified water. The filtrate was collected and tested with a pH meter. The pH value of the filtrate was between 9.0 and 10.0, and concentrated under reduced pressure at 75° C. (vacuum degree 0.090 MPa) until the moisture content of the oil was about 16%.

[0049] Add 100mL absolute ethanol to the oily substance and dissolve at 60°C. Add 0.51 g (1%, m / m) of sodium pantothenate seed crystals and stir to disperse evenly. Stir and crystallize at 26° C. for 3 h. After more white particles were precipitated, 90 mL of methyl ethyl ketone was added dropw...

Embodiment 3

[0054] Take calcium pantothenate (49.80g, 104.51mmol) and dissolve it in 100mL of purified water. Sodium carbonate (12.34g, 116.41mmol) was dissolved in 40mL of purified water. At 34°C, add the sodium carbonate aqueous solution dropwise to the calcium pantothenate aqueous solution, and the dropwise addition is completed in 15 minutes, and then stir at the same temperature for 20 minutes. Filter and wash the filter cake with 10 mL of purified water. The filtrate was collected and tested with a pH meter. The pH value of the filtrate was between 9.0 and 10.0, and concentrated under reduced pressure at 75° C. (vacuum degree 0.090 MPa) until the moisture content of the oil was about 19%.

[0055] Add 200mL of absolute ethanol to the oil and dissolve at 60°C. Then add 0.50 g (1%, m / m) of sodium pantothenate seed crystals, stir and disperse evenly, stir and crystallize at 18° C. for 3 h. After more white particles were precipitated, 90 mL of methyl ethyl ketone was added dropwise,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com