Anaerobic reaction system for treating livestock and poultry breeding sewage or high-concentration organic wastewater

A technology for organic wastewater treatment and anaerobic reaction, applied in the field of anaerobic reaction system, can solve problems such as gas production fluctuation, instability, and reduce effluent COD concentration, and achieve the effect of saving volume and investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

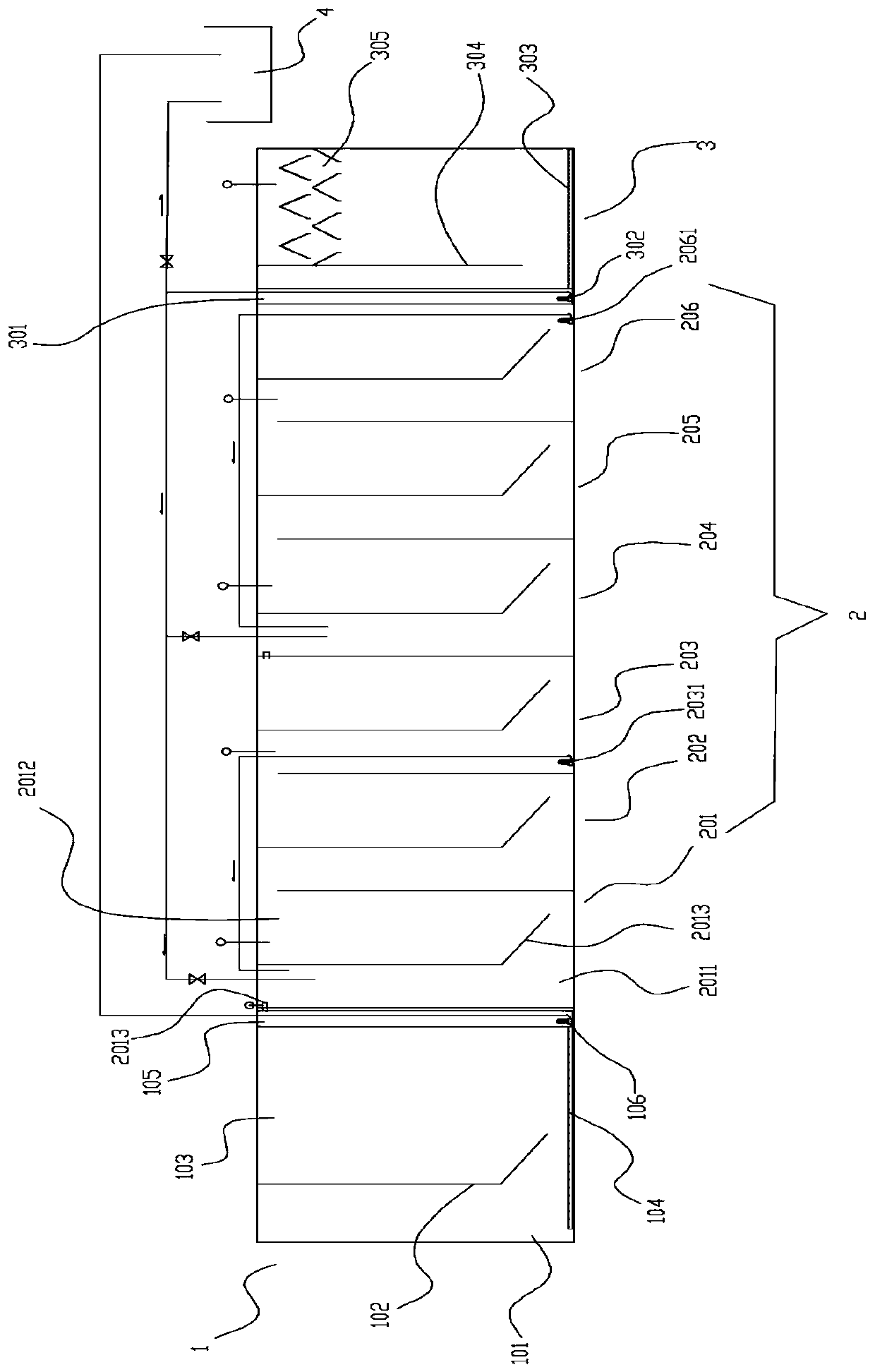

[0045] Such as figure 1 and figure 2 As shown, an anaerobic reaction system for the treatment of livestock and poultry breeding sewage or high-concentration organic wastewater, including suspended solids removal baffle reaction device 1, internal return anaerobic baffle reaction device 2, anaerobic sludge Collection device 3 and sludge thickening tank 4;

[0046] A solid-liquid separation device is provided before the suspended solids removal baffle reaction device 1. The solid-liquid separation device in this embodiment is a hydraulic screen type solid-liquid separator, and the liquid phase outlet of the hydraulic screen type solid-liquid separator is connected to the suspension Material removal baffle reaction device 1 communicates;

[0047] Suspended matter removal baffle reaction device 1 comprises suspended matter removal baffle reaction chamber, suspended matter removal baffle reaction chamber is provided with first baffle plate 102 along its longitudinal direction, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com